This article was previously published in Compound Semiconductor.

GaN as enabler of 5G

Wireless communications have rapidly evolved through several evolutions since their inception in the 1980s, with subsequent generations addressing an ever-growing demand for faster and more reliable communication. Despite these advancements, the explosive growth in data traffic and the need for higher bandwidth continues unabated, and even accelerates with the onset of the era incorporating Artificial Intelligence, and virtual reality. Currently, the 5th generation (5G) is starting to come online which represents a significant leap in capabilities. Operating today on sub-6GHz frequencies, 5G offers unprecedented data rates, ultra-low latency, and the capacity to connect a massive number of devices simultaneously. This has paved the way for new applications such as smart cities, autonomous vehicles, and the Internet of Things (IoT).

The sub-6GHz devices currently available are based on SOI (silicon on insulator) technologies and utilize the scalability of the silicon microelectronic industry. However, fundamental limitations in speed have opened the door to III-V materials to supplant silicon-based devices as the primary foundation for next-generation RF technologies. Among the promising materials are SiGe (Silicon Germanium), InP (Indium Phosphide), and GaN (Gallium Nitride), with GaN standing out due to its superior electron mobility, high breakdown voltage, and capacity for higher frequency and power operation. GaN-based devices are ideal for RF and microwave applications, including 5G infrastructure, radar, and satellite communications, thanks to their excellent thermal stability and efficiency.

MOS-HEMTs for GaN-on-Silicon technologies

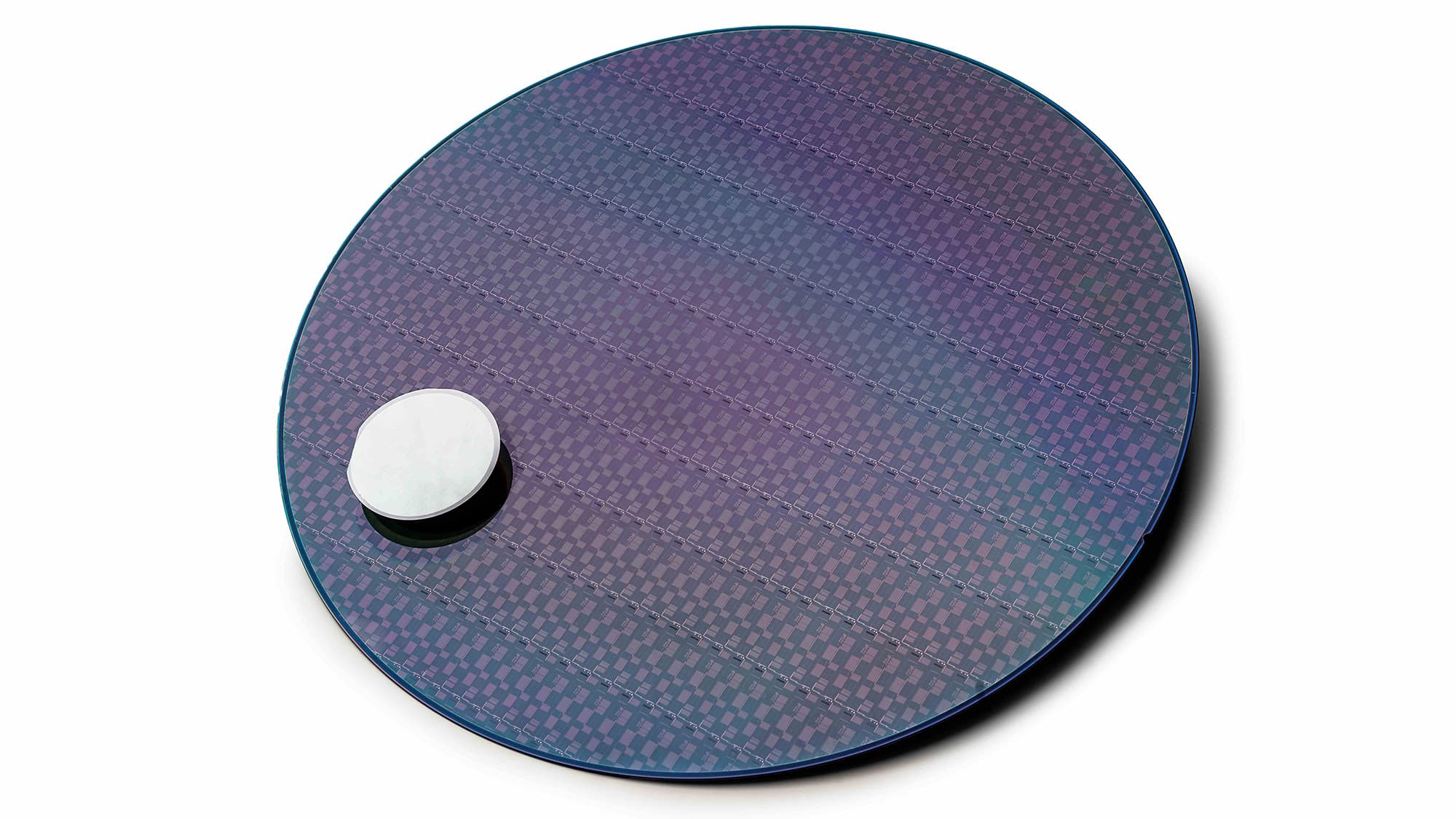

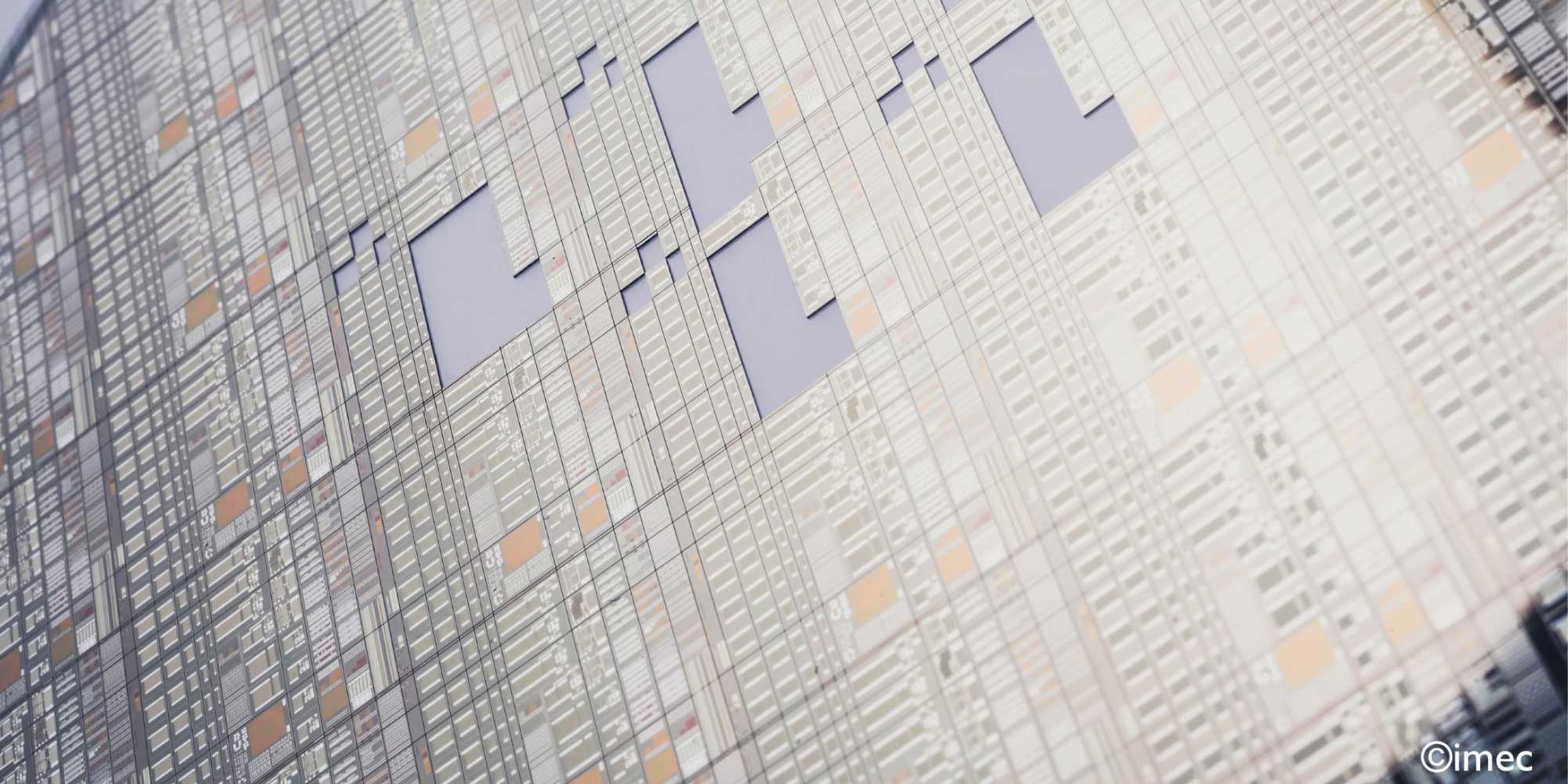

Currently, researchers at imec are exploring the potential of GaN-on-Silicon technologies for mm-wave RF applications in the FR3 frequency range (~7-25 GHz).

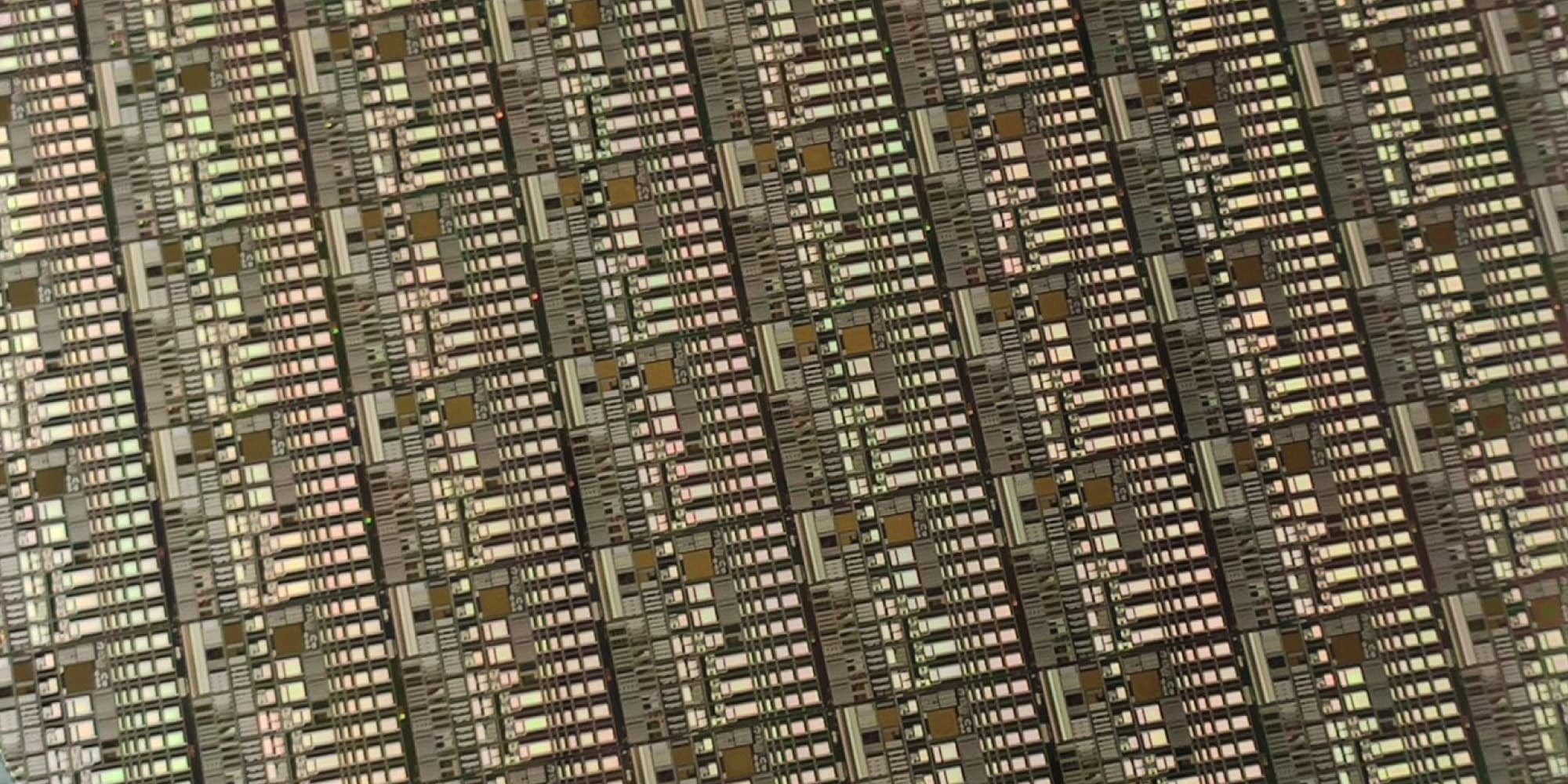

GaN power amplifiers show superior output power at mm-wave frequencies compared to other technologies, and when fabricated on silicon, they offer additional cost benefits. AlGaN/GaN HEMTs (high electron mobility transistors) are the core transistors used in these amplifiers due to their excellent high-frequency performance and ability to handle high power.

Both lateral (reducing width and length of the transistor) and vertical (adjusting the thickness of the layers) scaling are crucial for optimizing the performance of RF transistors in applications for 5G and beyond. Lateral scaling can enhance speed and frequency response, while vertical scaling is needed to manage short-channel effects that degrade transistor performance. However, continued vertical scaling can also lead to increased leakage currents, particularly when the transistor is in the on-state. One route to mitigate this effect is by inserting a high-κ dielectric between the gate metal and the AlGaN barrier, using a metal-oxide-semiconductor HEMT (MOS-HEMT) structure.

High-κ dielectrics have been used in silicon technologies for the same reason -to reduce leakage in ultrascaled transistors- for the last 20 years and are notoriously defective materials. Given the reliability challenges of incorporating them in Si-based logic devices, their impact needs to be studied in these MOS-HEMT structures.

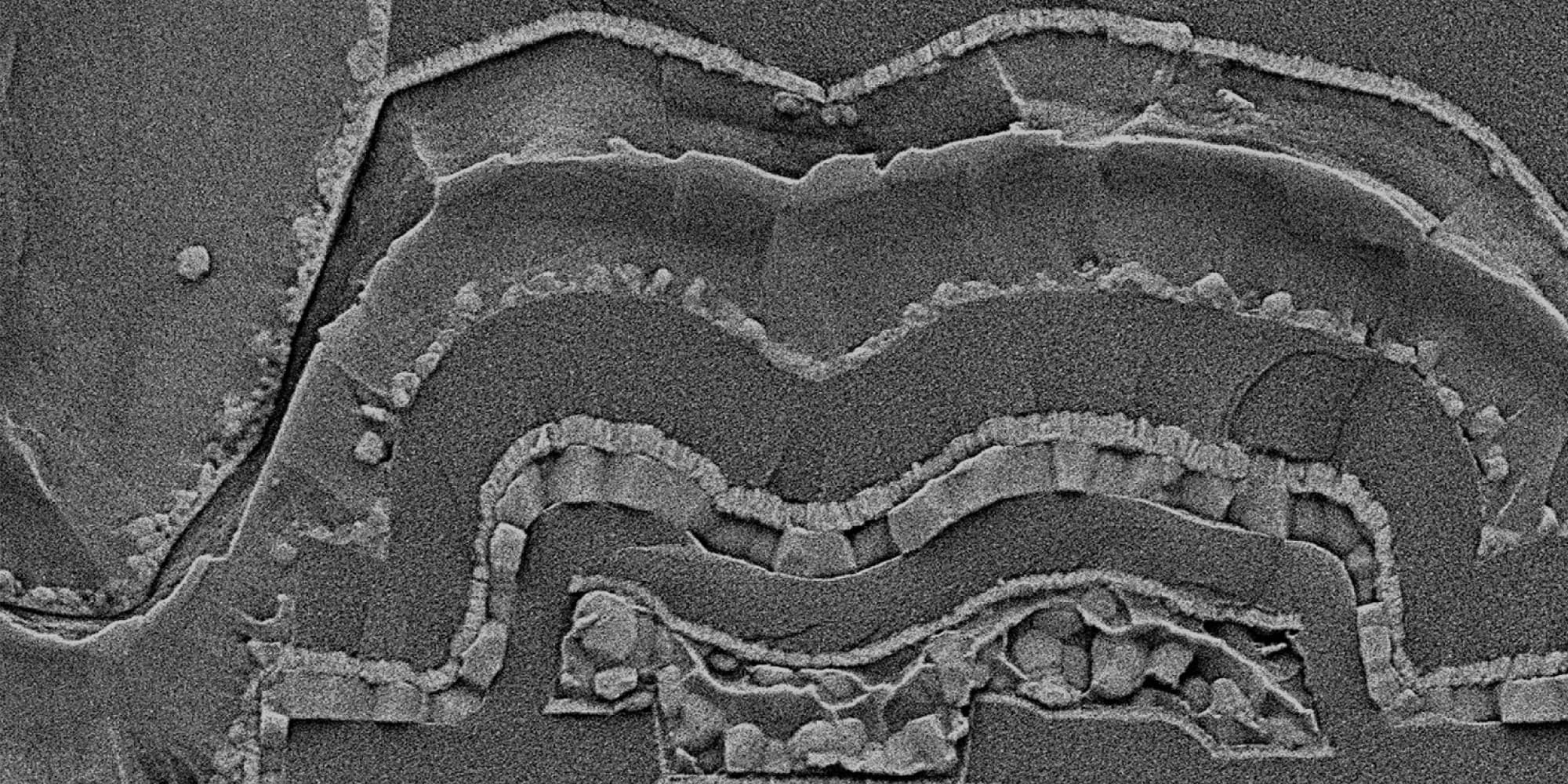

Figure 1 – Schematic design of MOS-HEMT devices with gate dielectric deposited in partially recessed AlGaN layer.

In this article, imec researchers present the main findings of one of the first reliability studies of GaN-on-Si for power amplifiers, recently shown at the 2024 IEEE International Reliability Physics Symposium (IRPS) and published in its proceedings. In particular, they show charge trapping and emission in the HEMT-structures with high-κ dielectrics, and succeed to isolate the physical and energetic location of the responsible defects. Trapping and emission occur when the charge carriers in the device are confined in or released from certain defects in the semiconductor or dielectric material. This impacts the performance and reliability of the HEMTs, especially in high-frequency and high-power applications. The results of this study will help define the best material combinations and layer thicknesses in the overall process optimization for these devices.

Significant electron capture from the bulk dielectric in MOS-HEMTs

One of the main reliability concerns that affects MOS-HEMTs is bias temperature instability (BTI), referring to the transistor’s degradation over time due to prolonged exposure to electrical stress (bias) under certain temperature conditions. It is caused by the trapping of electrons in the dielectric or the interface between the dielectric and semiconductor layers. BTI causes gradual shifts in the threshold voltage (Vt), meaning that transistors require more voltage to switch on, which reduces the speed and efficiency of circuits.

The imec researchers mimicked BTI by applying a DC voltage or ‘stress’ on a MOS-HEMT device with either HfO2 or Al2O3 high-κ dielectrics and monitoring the Vt. In the case of Al2O3-stacks, Vt increases as a function of time and bias, which points to defects present over a wide bias and energy range. In the case of HfO2, two modes of degradation are observed. At lower voltages the results show HEMT-like time-independent and negligible charge trapping, while at higher stress bias significant Vt shifts are observed, with a power law increase with time and bias until it saturates at ~300mV. This high bias dependance suggests a relatively narrow defect type in this stress range.

Are the charges trapped in the bulk dielectric or the interface? The researchers could differentiate between both locations by observing how the Vt shift responds to changes in thickness of the high-κ dielectric, capacitance measurements and simulations. They found that most of the charge trapping happens in the bulk dielectric.

Figure 2- The charge trapping characteristics of MOS-HEMT structures with HfO2 or Al2O3 high-κ layers. Al2O3 results shows Vt increasing as function of time and bias, suggesting defect types with a wide energy range. HfO2 on the other hand shows negligible trapping at low biases but there are significant Vt shifts at higher bias. This points to a relatively narrow defect type in this bias range. Figure based on O'Sullivan et al. IRPS 2024.

Emission behavior in HfO2 MOS-HEMTs suggests 3 types of defects

Trapped charges can be released or emitted when the stress is switched off. Analyzing emission dynamics provides insights into the reliability of the device (recovery of Vₜ) and the origin of the defects. The results show that the defects responsible for the Vₜ shift in Al₂O₃ release their charges quickly and completely whereas, for HfO₂, charge emission occurs more slowly and remains incomplete, suggesting a different type of defect.

To determine how many types of defects are present, the experimental results were fitted to the universal relaxation model. This model assumes that every type of defect has its own characteristic energy that is following a certain distribution. Fitting the model to the HfO2 data clearly shows that more than one defect level is at play; the emission data is not overlapping with the model. The simulation only considered defects that display complete emission (the Vt is recovered), but in some cases the trapped charges do not emit from the defect (the Vt change is permanent). Adding this permanent component to the model, the model and the data are closer aligned. Closer, but not perfect. Even though the difference is only 10mV, it suggests a total of 3 different defect types present in the HfO2 MOS-HEMTs. On the other hand, literature studies on Al₂O₃ dielectrics previously identified only two defect types contributing to the charge trapping. However, the wide distribution of defects in Al₂O₃ complicates further detailed analysis.

Figure 3– (Top) Emission kinetics of (left) HfO2 and (right) Al2O3 MOS-HEMTs after stressing for increasing times. Note the difference in emission behavior between the Al2O3 and HfO2, which only partially emits. (Bottom) Fitting of the data to the universal relaxation model shows that HfO2 emission is described by (left) a recoverable component, (right) a permanent component and a third component, as the data doesn’t match the fit well. Figure based on O'Sullivan et al. IRPS 2024.

Identifying and locating defects in HfO2 devices

In the next step, the researchers studied how these defects contribute to the Vt shift, which gives insight into device stability. By calculating the activation energy needed for defects to capture and release charges, the researchers were able to map out 3 different defect types for HfO₂. A low thermally-activated defect (R1) captures and emits electrons quickly, while two higher activation-energy defects (R2 and R3) have similar charge capture rates but emit charges differently.

The band diagram revealed that as the bias voltage is applied, electrons are captured into a shallow defect in the dielectric, located about 2 eV below the conduction band of HfO₂. This defect level is not accessible energetically at low stress bias which explains why charge trapping becomes more pronounced at higher voltages and that the process depends on how much bias is applied.

When the bias is removed, the band diagram also helps explain why some of the captured electrons are emitted back into the GaN channel, leading to a recoverable Vt shift (R2). Other electrons, however, remain trapped in the energy barrier between the HfO₂ and AlGaN layers, resulting in a permanent Vt shift (R3). The different emission behavior shows that even though the same defect type is responsible, it needs to be modeled as two separate defects due to these two emission pathways. A deeper defect (about 3 eV below the conduction band) was also identified, contributing to a negative Vt shift (R1), as these trapped electrons are lost during recovery.

Figure 4– (Left) The activation energy map for HfO2 MOS-HEMT showing the 3 defect types modelled to explain the measured BTI behavior. (Right) Simulated band diagram of HfO2 MOS-HEMT, showing electrons filling the shallow defect during capture and emission from 3 defect types. Emission from the shallow defect can be either to the channel (recoverable) or the AlGaN conduction band (non-recoverable), while simultaneously the deep HfO2 level can be charged explaining the increasing Vt seen at low temperatures. Figure based on O'Sullivan et al. IRPS 2024.

Towards more reliable e-mode MOS-HEMT devices

This study provides crucial insights into how different high-κ dielectric materials, such as HfO2 and Al2O3, affect the performance and reliability of MOS-HEMT devices. The identification of multiple defect types in HfO2, with varying charge capture and emission characteristics, highlights how these materials respond differently under electrical stress. Al2O3, with its faster charge recovery, may offer better stability for applications requiring rapid switching, while HfO2 shows more persistent threshold

voltage shifts due to slower emission, which could impact long-term device reliability. Additionally, HfO2 has higher defect densities, but they are energetically distributed across narrow energy ranges, whereas Al2O3 has lower density of defects, but the responsible defects are distributed over a broader energy range. These findings are significant for optimizing material combinations and layer thickness choices in high-frequency, high-power devices, allowing for improved designs that balance performance and durability across a range of applications.

In a following step, the findings remain to be compared to enhancement-mode (E-mode, i.e. Vt>0V) MOS-HEMT devices. Although intrinsically HEMT-structures are depletion-mode (D-mode, the device is switched on at 0V), E-mode is preferred for RF applications as it reduces power consumption and increases reliability. Additionally, E-mode operation simplifies circuit design, eliminating the need for voltage shifters that create the negative voltage to switch off D-mode transistors, or for a multi-step device turn-on which prevents short-circuits and power surges in D-mode. Finally, the RF performance of MOS-HEMTs with these dielectric layers and the interaction between the defect levels remain to be studied.

Want to know more?

- These results were presented at the 2024 IRPS conference. Read the details in the conference proceedings: B. J. O'Sullivan et al., "DC Reliability Study of high−κ GaN-on-Si MOS-HEMT's for mm-Wave Power Amplifiers," 2024 IEEE International Reliability Physics Symposium (IRPS), Grapevine, TX, USA, 2024, pp. 1-9, doi: 10.1109/IRPS48228.2024.10529379.

- Take a look at our website for more information on GaN for power devices https://www.imec-int.com/en/200mm-GaN-on-Si-technology and RF devices https://www.imec-int.com/en/expertise/solutions-5g-and-wireless-iot-communication/beyond-5g-technology

Barry O’Sullivan is a Principal Member of Technical Staff in the Advanced Reliability Robustness and Testing Department of imec, Leuven, Belgium. He received the Ph.D. (2004) degree from the Tyndall Institute, Cork, Ireland, and performed postdoctoral studies at imec characterizing advanced silicon-based devices, before working with Matsushita Electric on reliability for the 45 / 32 nm CMOS technology nodes. Since 2006, his research topics at imec have included high efficiency silicon photovoltaics, reliability and characterization of advanced devices for logic, photonic and memory applications, and more recently extended to GaN HEMT devices for RF / mm-wave applications.

Published on:

12 March 2025