Exploration of optical underfill rheology and wettability in nanogaps for advanced photonic packaging applications

Master projects/internships - Leuven | More than two weeks ago

Advance photonics packaging techniques by understanding how complex fluids behave inside sub-micrometer-sized gaps

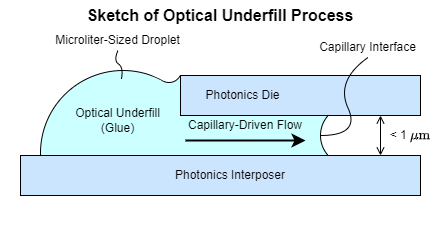

Advances in photonics packaging technology are enabling products consisting of multiple photonic dies interfaced together within a single packaged assembly. A critical aspect for this technology is the reliable bonding of photonics components using optical underfill materials. Optical underfills play a crucial role in mechanical stability of the package as well as functioning as an interface for optical interconnects located on separate dies. However, the complex rheological and wetting behavior of commercial optical underfill materials poses a significant challenge in predicting the capillary filling process particularly in sub-micron size gaps required for relevant photonic applications.

The primary objective of this research is to experimentally investigate the influence of optical underfill properties on capillary flow within a nanogap. Specific objectives include:

- Evaluate viscous effects and related hydrodynamic phenomena within nanogaps

- Investigate the capillary wetting behavior of optical underfills within nanogaps

- Understand the impact of nanogap height on the underfill rheology and wetting characteristics

During the experimental studies, the following will be conducted by the student:

- Measuring bulk viscosity, surface tension, and contact angle using traditional methods and tools

- Design and construct simple devices and experiments to characterize the materials within nanochannels and/or nanogap

- Nanofabrication in the cleanroom may be involved in the device fabrication

- Optical microscopy techniques as well as pressure/flow sensor measurements will be utilized

- Data will be analyzed using Excel and/or Python scripts

Prospective candidates should have a keen interest in hands-on experimental work. Ambition to learn and willingness to develop new skills are critical. Prior background in fluid mechanics (either in academic studies or practical experience) is highly preferred. At imec, the selected candidate will work in a diverse, dynamic, multi-disciplinary team and gain expertise in the challenges of semiconductor manufacturing, setting the stage for a fruitful career in R&D supporting a high tech industry.

Type of Project: Thesis

Master's degree: Master of Engineering Science

Master program: Mechanical Engineering; Chemistry/Chemical Engineering; Electromechanical engineering; Materials Engineering

Duration: 6 to 12 months

Supervisor: Houman Zahedmanesh

For more information or application, please contact Ben Jones (ben.jones@imec.be).

Only for self-supporting students.