Driving Reliability: Tackling Uncertainty for Reliability Predictions in Automotive Chiplet Technology

PhD - Leuven | More than two weeks ago

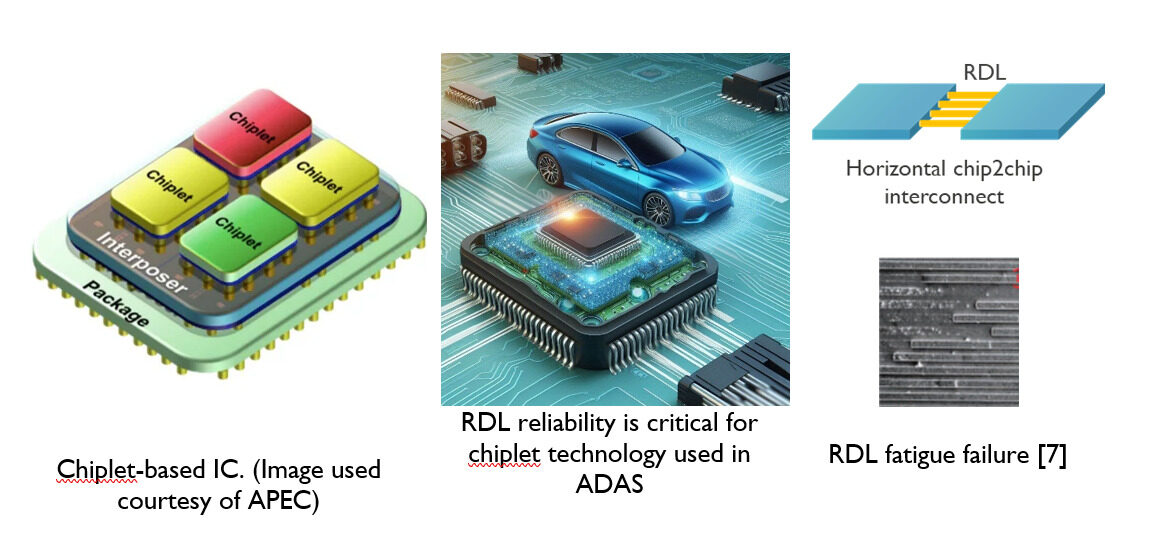

Background: Chiplet technology represents a significant advancement in semiconductor packaging, allowing for the integration of multiple smaller chips (chiplets) into a single package. This approach offers numerous benefits, including improved performance, reduced costs, and enhanced design flexibility. In automotive applications, where reliability and performance are critical, chiplet technology can provide the necessary computational power and efficiency for advanced driver-assistance systems (ADAS), infotainment systems, and other electronic control units (ECUs).

Redistribution Layers (RDL) are essential components in chiplet technology, serving as the interconnects that redistribute the input/output (I/O) connections of the chiplets to different locations on the package. This redistribution is crucial for achieving the desired electrical performance and mechanical reliability. However, the mechanical reliability of RDLs is a significant concern, particularly in automotive applications where the operating conditions can be harsh and variable.

Problem Statement: The mechanical reliability of RDLs is influenced by various factors, including material properties, microstructural variations in the metallization, and the stresses induced during operation. In automotive applications, these factors are exacerbated by the wide range of operating temperatures, vibrations, and mechanical loads. Ensuring the reliability of RDLs under these conditions is challenging due to the inherent uncertainties in material properties, microstructural characteristics and operational conditions.

As such, the traditional reliability assessment methods may not adequately account for these uncertainties, leading to potential failures in the field, especially for reliability-critical applications such as automotive where failure may result in safety issues. Therefore, there is a need for advanced methodologies that can quantify these uncertainties and provide more accurate predictions of systems reliability under extreme thermal-mechanical operating conditions.

Objectives:

The primary objectives of this research are:

- To explore the aging mechanisms for RDL including metal interconnect’s fatigue, ratcheting, stress induced voiding and polymer-related reliability mechanisms such as creep, change of properties with aging e.g. embrittlement and delaminations.

- To quantify the uncertainties in material properties and microstructural variations of metals and changes of mechanical properties of the polymer matrix and their correlation with reliability mechanisms. In addition, by quantifying the uncertainties in fabrication process and the operational conditions e.g. workloads and mission profiles of chiplets in automotive applications.

- To explore processes and flexible design strategies for stress mitigation to enhance reliability while co-optimizing with electrical performance.

Related reading:

[2]https://www.3dincites.com/2024/07/chiplet-test-piecing-together-the-next-generation-of-chips-part-2/

[3] https://www.imec-int.com/en/expertise/cmos-advanced-and-beyond/compute/automotive-chiplet-program

[4] https://www.imec-int.com/en/articles/chiplets-piecing-together-next-generation-chips-part-i

[5] Yip et. al, "Reliability Challenges of High-Density Fan-out Packaging for High-Performance Computing Applications," 2022 IEEE 72nd Electronic Components and Technology Conference (ECTC), San Diego, CA, USA, 2022, pp. 1454-1458, doi: 10.1109/ECTC51906.2022.00232.

[6] Narashiman et al., Chiplets on Wheels: Review Paper on Holistic Chiplet Solutions for Autonomous Vehicles, arXiv:2406.00182v1 [cs.AR] 31 May 2024.

[7] Li et. al, High-toughness (111) nano-twinned copper lines for fan-out wafer-level packaging.

[6] Matthies, Hermann G. (2007). "Quantifying Uncertainty: Modern Computational Representation of Probability and Applications". Extreme Man-Made and Natural Hazards in Dynamics of Structures. NATO Security through Science Series. pp. 105–135.

Required background: Engineering Technology, Engineering Science

Type of work: 10% literature and technological study, 60% to develop efficient computational models, 30% to design and conduct experiments to calibrate and validate the computational models.

Supervisor: Prof. dr. Ir. Houman Zahedmanesh

Co-supervisor: Prof. Mehdi Tahoori

Daily advisors: Abdellah Salahouelhadj, Houman Zahedmanesh

The reference code for this position is 2025-007. Mention this reference code on your application form.