Nanoelectronics for space exploration

Leverage imec’s innovative technologies and radiation-hardening capabilities for a new generation of satellites for Earth and space exploration.

Next to the heavyweights, a new generation of ever-smaller satellites is in the making. Imec is one of the world’s specialists in scaling innovative technology ever smaller while at the same time improving its specifications. We have the expertise to develop integrated imagers, radiation-hardened circuits, optical transceivers and efficient power conversion components. According to your specs, in dedicated development-on-demand projects.

In addition, we have extensive experience in the field of space evaluation (ESCC2269000) and qualification (ESCC9000). This includes developing and customizing the hardware required for screening flight modules such as test load boards, packages and sockets as well as managing the whole supply chain.

Last, we are pioneering some amazing technologies that fall right into what is needed for next-generation spacecraft: photonics-based communication chips, sensors for astronaut health monitoring, and flexible photovoltaic panels with woven interconnects.

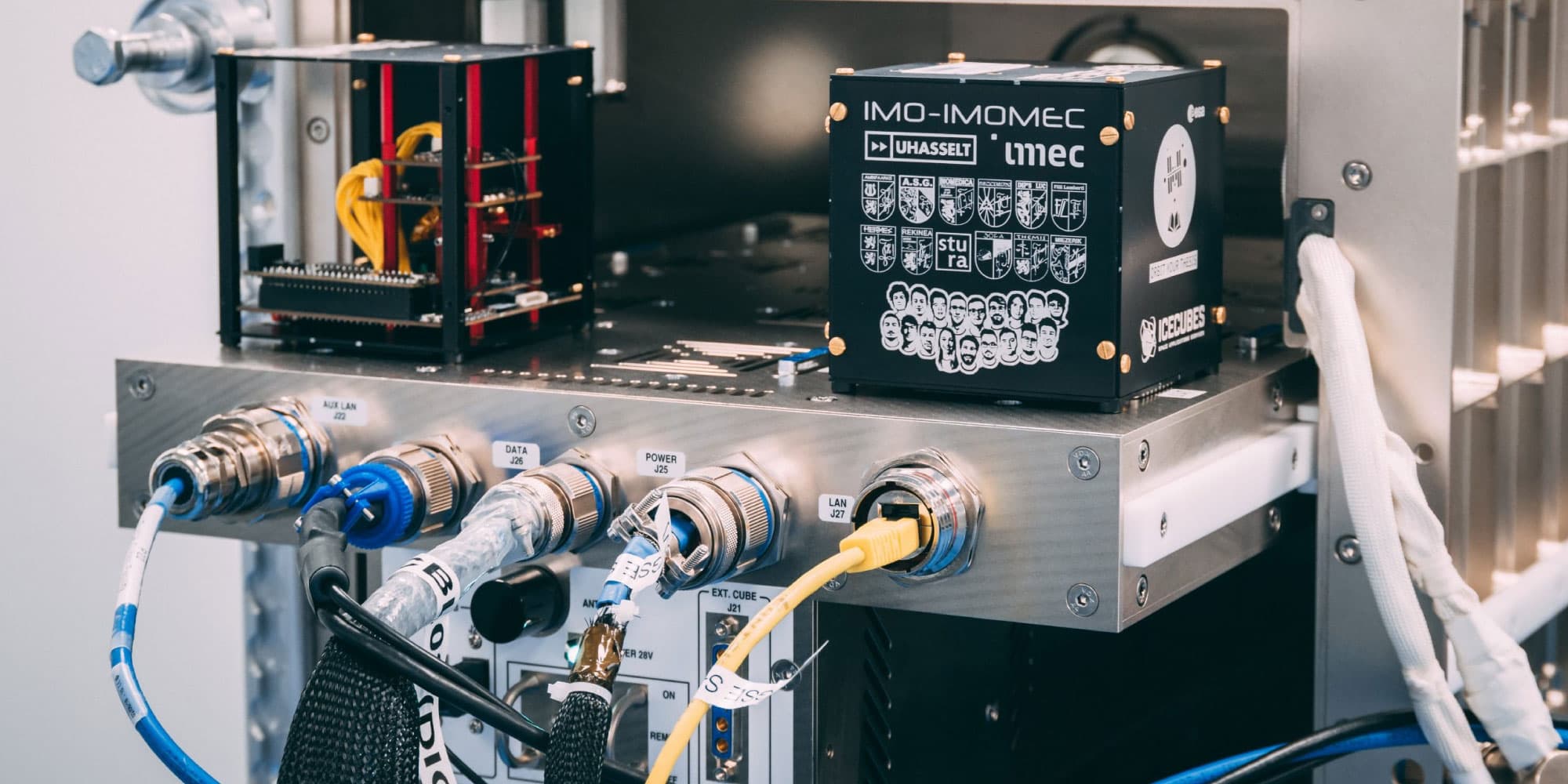

2024 research update: Imec’s technology validated in suborbital space flight

Several foundries that used to offer technologies for radiation-hardened ASICs have left the market. To provide a high-quality alternative, imec has developed the DARE platform (Design Against Radiation Effects). DARE is a combination of digital cell libraries, methodology support for analog design and the re-use of predesigned analog IP blocks. DARE was developed and is maintained with support from the European Space Agency (ESA).

The DARE methodology and flow allow for the integration of existing and custom-designed digital and analog blocks on a single chip. It also supports the required steps to deliver flight models manufactured in the technology and assembled in the package best fit for your application.

Imec is:

- Hardening building blocks in a selection of standard CMOS technologies by applying proven techniques for layout and circuit design.

- Providing your analog designers with a Cadence ADK (Analog Design Kit), allowing a smoother design flow and checks for technologies ranging from 0.35 um to 65 nm.

- Using an adapted digital place & route method to mitigate against Single Event Effects.

- Providing access and support for manufacturing, testing, evaluating, and lot validating flight models of DARE-based components.

Imaging sensors for space and Earth observation

We invite you to come and challenge us with your imager specs. We realize imagers customized according to your specifications, from design and development up to low-volume manufacturing.

Our scientists have micro-sized and integrated a wide array of imager technologies in silicon, technologies to capture visual data with high ground resolution and spectrally filtered (multi/hyperspectral images). But above all: we have a platform to design and prototype specialty imagers and adaptations to specific specifications.

- CCD-in-CMOS for time delay integration (TDI) imaging: combining the high level of integration and power efficiency of CMOS technology with low noise, high speed CCD technology

- hyperspectral cameras for satellites and space exploration vehicles

- ultra-high-speed imaging

- development on demand, both at pixel and at imager system-on-chip level

TDI imager made with imec's CCD-in-CMOS process.

Efficient power electronics for DC/DC energy conversion

Efficient DC/DC convertors that supply all equipment with stable power are key components of any satellite. Imec’s power electronics are up to the task. Based on gallium nitride (GaN) technology, they are compact, integrated and radiation-hardened. We can offer you assistance with any or all of the fabrication steps, from idea up to testing and qualification.

- GaN-on-Si transistors with exceptional specifications

- e-mode power devices, without degradation after heavy ion and neutron irradiation

- monolithically integrated circuits

All these components are radiation-hardened and proven in a number of high-stakes ESA projects.

Free-space optical transceivers

Communication in space – such as between satellites – often relies on directional and secure optical links with high bandwidths. The transceivers that establish these links must be:

- compact

- low-power

- sufficiently robust to survive the harsh conditions during and after a launch

Integrated photonics, which doesn’t rely on moving parts, is the ideal technology for this. And it’s ready for implementation in your application thanks to imec’s hybrid optical beamforming platform.

Develop your nanotechnology for space exploration with imec

Imec is with you in all stages of the design and fabrication of radiation-hardened electronics. In addition, we have a wealth of technological solutions for your next-generation satellites. Join us as an R&D partner to further develop and customize the innovative technological solutions at the heart of space exploration.