When the ‘Internet of Things’ (IoT) really joins up the dots

In a not so distant past, the telephone and the Internet started connecting places and then the mobile phone did the same thing with people … And now we are ready for the Internet of Things (IoT). Probably the applications that spring most readily to mind for the ordinary citizens are mobility (driverless cars) and the smart city (measuring air quality, smart traffic lights and so on).

But the IoT is also demonstrating its value in other areas. Farmers use it to monitor the health of their dairy herds. And you’ll find other applications in for example the smart supermarket or in a suitcase that you’ll never have to worry about losing again. In fact, thanks to imec’s knowledge portfolio and collaborative programs, we are closely involved in a number of IoT projects that appeal to the imagination.

MoniCow: big brother watching cows

It is six o’clock in the morning on a midweek day at the Research Institute of Agriculture, Fisheries and Food (ILVO) in Melle (B). In the cowshed, fifty or so cows are just waking up. The on-duty livestock farmer is also beginning his day. Sitting with a reviving cup of coffee, he looks at his computer screen, which displays a summary of the main health parameters of every cow. Fortunately, everything is fine with the animals this morning. So the farmer can head off and take care of his herd as soon as he has had his own breakfast.

Collar with integrated accelerometers and temperature sensors, used in the MoniCow project.

The health of these animals is important – both for their own wellbeing and for the profitability of the cattle farm. Because if an udder infection or symptoms of lameness in a cow are noticed too late, it can cost the farmer hundreds of euros. Technological advances in livestock management are already supporting farmers with a whole range of tools. Unfortunately, the systems for monitoring cattle still have a number of limitations. For instance, their functionality is focused mainly on a single specific application and data from different systems is not always easy to combine. Plus, the autonomy of the batteries used in the sensors tends not to be long enough either.

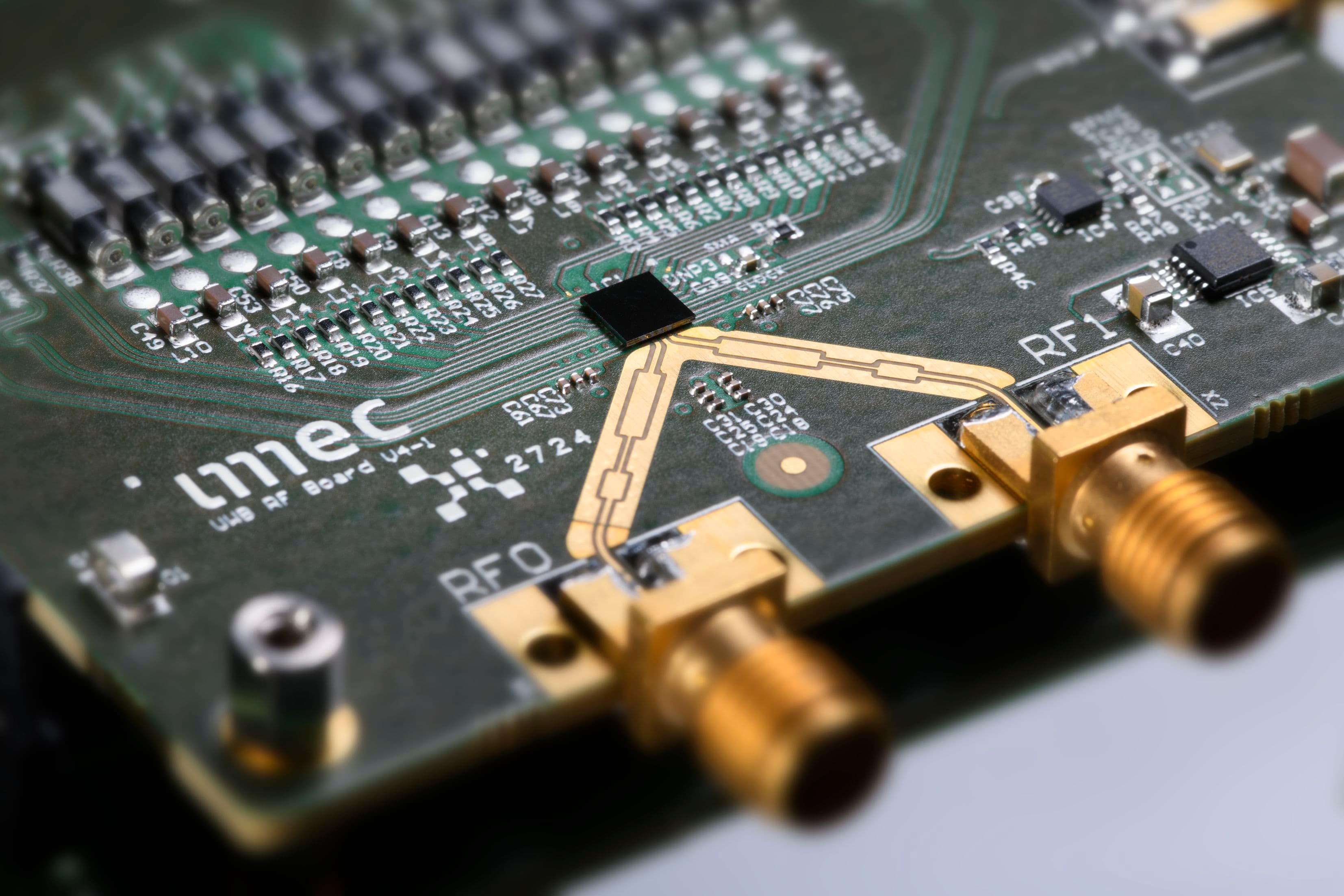

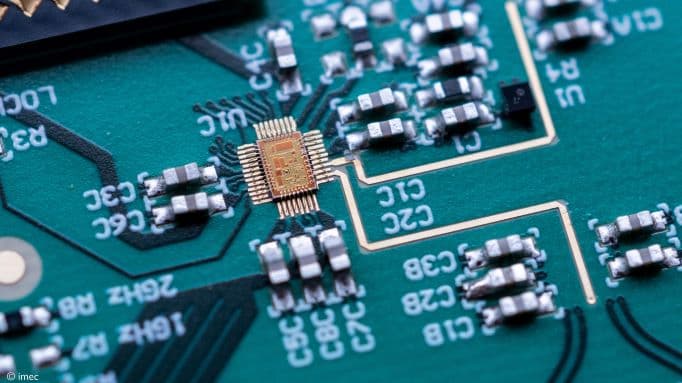

So, some three years ago, livestock farmers came to Ghent University asking for a solution that was more integrated and energy-efficient. From this request arose the imec.icon MoniCow project. As part of the assignment, farmers, knowledge institutions and businesses worked together for over two years to come up with an appropriate solution. This solution was then tested extensively at ILVO. To sum it all up, the solution to the farmers’ request consists of sensors that are integrated into the cow’s collar: accelerometers to analyze movement and sensors to measure temperature. The location and walking patterns of each animal can also be defined accurately via a network of ultra-wideband (UWB) transmitters.

David Plets, Professor at Waves, an imec research group at Ghent University, represents imec on this project: “We are very proud of the results from the MoniCow project. In total, fourteen cows were involved in our extensive pilot. The data collected shows that there is a good correlation between the measured behavior of the animals and the times at which, for example, they are in season or about to calf. This is very useful for the farmer and enables attention to be focused on animals that need it at that particular time. On a technical level we are also very pleased with the inductive charging system that we have built in, which enables the sensor batteries to be recharged wirelessly while the cow is for example waiting during milking or at feeding time. We have also worked with the industrial design course at Ghent University, with one of the students designing a housing for the device that not only looks good, but also optimizes the position in the charging system.”

David Plets also saw some unexpected results emerge from the research: “We also came to realize that from our data we can deduce the time a cow spends chewing the cud. There were already systems able to measure the time spent, but the way it was done is rather uncomfortable for the cow, which limits the number of measurements. With our system, the information comes ‘into the bargain’ with the data that we collect all of the time to analyze the cow’s movements.”

The knowledge gained through this project has already seen ten articles published in scientific magazines, as well as thirteen papers presented at various conferences. Equally important is the further development needed to take the system to market. The industrial partners in the program were DeLaval, ILVO, Metagam, Multicap, NXP Semiconductors Belgium and snapTonic. Some of them are currently researching to see whether the MoniCow prototype can be developed into a saleable product. But first there needs to be a more large-scale validation of the algorithms, among other things. Expanding the system to other markets – such as caring for horses – is another possibility. The first products for livestock farms are expected to be available in about two years’ time.

LUNAR: the efficient supermarket

Who doesn’t love the cow’s refreshing glass of milk or – for the non-vegetarians among us – a delicious juicy steak! So let’s go and buy these products at the supermarket. Which is where IoT applications are gradually making their mark in the way we shop.

Eli De Poorter is a professor at IDLab, an imec research group at Ghent University. “Under pressure from online shops, supermarkets and other retailers are looking for ways to redefine bricks-and-mortar shopping experience and to make it more attractive. For example by having a little screen on your shopping cart. The screen would then give shoppers personalized information, depending on where they are in the store. Plus, if they enter their shopping list into the system, their screen will display the fastest route round the store to find the items. And if they take a product from the shelves, they are given a recipe, as well as the route to find all of the extra ingredients they need to make the dish. The system even takes account of dietary and allergy information. And who wouldn’t want real-time information about waiting times at the check-out?”

Eli also sees benefits for the supermarket itself: “The owner can look at heat-maps to see where customers have to wait for too long in his store. He can also analyze whether certain product special offers are being successful or not. Are customers spending time at a particular advertising display? Or are they walking straight past? And it can be helpful for new employees when they have to refill shelves or give customers information.”

A number of these scenarios have been tested in the LUNAR project. For example, the possibility to use ultra wideband technology (UWB) to track the shopping cart in the store and then offer additional services based on the route taken. Observation of end-users provided some crucial insights into the process. De Poorter again: “First we attached a tablet to the bar that you push the shopping cart with. We provided real-time updates by determining the customer’s location several times a second and then made changes to the information on the screen accordingly. In fact, to our surprise, this information had the opposite effect! Shoppers were so focused on the constantly changing display on the screen right in front of their face that they kept bumping into other customers and knocking obstacles in their way. So we made changes to the system and the tablet is now located at the back of the cart. We have also significantly reduced the information refresh rate and only provide updates when they are relevant, for example when someone stays for some time in a particular location.”

Shopping cart used in the LUNAR project to make shopping a more efficient and pleasant experience, for example by showing you the fastest way to the products you need.

LUNAR was also a successful project, technically speaking. De Poorter: “In fact, the system appears to be able to do more than we originally intended, or at least what was strictly necessary for the initial applications. For example, continuous updates are not required for this specific application. We can also pinpoint a person and their cart to within 15 centimeters, whereas our aim was 30 centimeters. And while we wanted to be able to track 200 shopping carts in a space of 2 000 m², we can actually accommodate up to 6 000 carts! We can do this because we have applied the wireless communication protocols in such a way that the carts only transmit information if other carts in the vicinity aren’t. That way we can avoid having two signals interfere with one another and creating confusion when it comes to interpreting data.”

As with MoniCow, the results from LUNAR are also finding their way to market. Pozyx, a Ghent-based start-up, is already enjoying the first fruits of their labors. Michael Van de Velde, VP sales & marketing at Pozyx: “Thanks to the LUNAR project, our business has been able to grow and we now have fifteen staff and over three thousand customers. Companies such as AB InBev and SpaceX are buying our products in which we use the knowledge we developed in the LUNAR project.”

Imec makes it possible

Both MoniCow and LUNAR are alumni of the imec.icon program in which imec supports requests for innovation submitted by companies. Imec was also one of the project partners. Michael Van de Velde again: “In the LUNAR project, the imec researchers were responsible for the antenna design that we still use in our products.” Says David Plets, “With Monicow we used our expertise to optimize communication. There tends to be a lot of metal in cow stalls and the bodies of the cattle also get in the way of the wireless signals. The power and other parameters of the communication signal need to be adjusted to be able to send reliable information without using up too much energy. Working with Multicap from Hove, we also contributed to the location algorithms and carried out a technical and economic study to determine the economic feasibility.”

Let there be no mistake: working with imec does not always mean taking the most advanced hardware out of the lab.

In many cases, imec offers a unique insight into improving the partner company’s existing technology.

Eli De Poorter: “Our partners’ involvement in these IoT projects is often very significant. For both the companies and the people conducting the tests, the applications are close to their daily practice. This motivates them and also makes the collaboration exciting for us.”

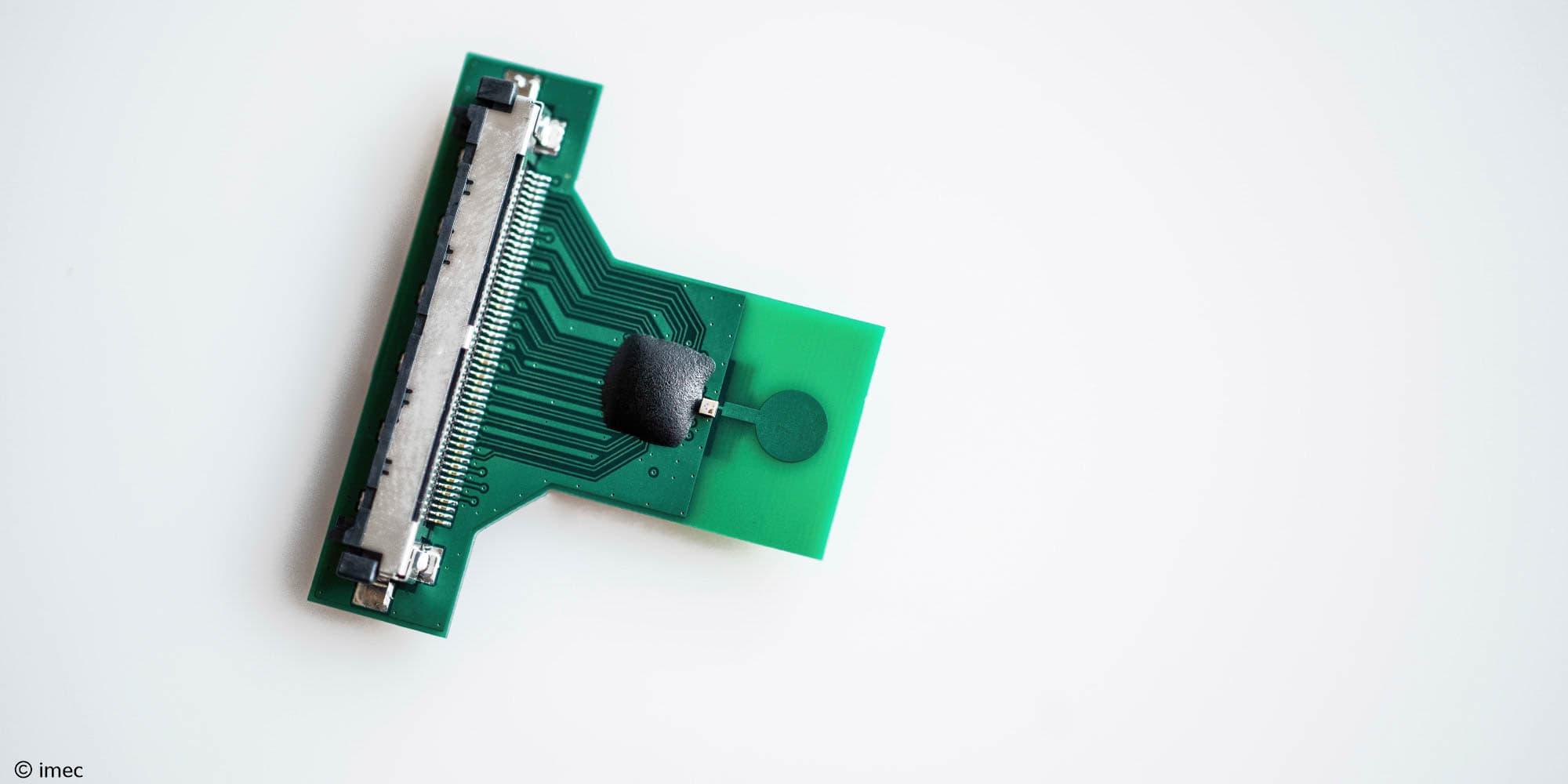

Of course imec also develops cutting-edge technology for IoT applications. One example is radar-based technology for accurate indoor localization. This technology is less invasive for the personal working and living space than camera-based systems. And it is compatible with Bluetooth. It can also be deployed for what is known as ‘secure proximity detection’. Applications include automatic doors or a front door that unlocks itself when you approach with your key or smartphone. Thieves are becoming increasingly successful in hacking into this type of system with so-called ‘relay attacks’. They use a small device for picking up the wireless signal and amplify it when your key or phone are close to the door. But with imec’s radar technology attacks such as these are impossible.

Bluetooth-compatible technology for secure proximity sensing, as recently presented by imec and its partners

Smart suitcase: the sky is the limit

And the applications are literally endless. Jeroen Hoebeke, Professor at IDLab, an imec research group at Ghent University: “IoT has now become a catchall.

For me it’s mainly about objects that weren’t originally made with connectivity in mind.”

One of the recently launched imec.icon projects is focusing on developing a smart suitcase. A suitcase such as this is “smart” because it can weigh itself and never goes missing.

Jeroen Hoebeke: “We are also seeing interesting developments in sport, an area where so many parameters are measured. How do you take accurate measurements in real-time with professional athletes? How do you give them useful feedback? In team sports, how do you carry out comprehensive contextual analyses of people’s relative positions? In football, for example: is there a link between the position of defenders and the scoring ability of forwards? There are already sensors in the ball or the players’ boots that can measure the interaction between the ball and the player. In track cycling you can analyze what the ideal positions and pedal power are to achieve maximum speed with minimum fatigue. And once the technology has been developed, the challenge is often to make it available at an entry level for amateur clubs and sportspeople.”

IoT sensor for track-cycling applications

The scale of the projects is often a challenge, too. Jeroen Hoebeke: “Not only in farming, retail and with the smart suitcase project, but also in many logistics-based projects, I am constantly surprised at how many measuring points there are and how wide the distances are that have to be bridged. This also places specific demands on the technology and the way it is implemented. For example wanting to track a suitcase at the airport or a package in a store to within just a few centimeters is one thing. But if you also want to follow it when it’s on the move, on the road or in the air, then a level of accuracy down to a few hundred meters is all you need. In logistics it is also difficult to integrate IoT applications into the existing technological infrastructure. Companies often make major investments in a system from a particular supplier,which turns out to be difficult when you want to add new elements to it. Having said that, I see a high level of willingness to adopt new technologies and standards. The sector is moving fast and that means great flexibility is needed to generate a return on investments in automation over the longer term. Amazon is a good example of this. It is no coincidence that they are an IT company that has specialized in smart logistics.”

One thing is clear: the limits of IoT applications are a long way from being reached and imec is giving a helping hand to companies that want to make use of the very diverse range of technologies and services on offer.

Want to know more?

- Do you have an innovative idea in ICT, our health and care sector, the manufacturing industry or other domains? Read all about the imec.icon open call or contact Steven van Assche, imec.icon Program Manager.

- On the MoniCow project page, you can find a news item by Kanaal Z, the Flemish business broadcaster.

- The LUNAR project page tells you more about the project.

- Recently, imec published a a press release on secure proximity sensing based on Bluetooth.

In 2006, David Plets graduated as Master in Electrical Engineering, with a major in ICT. Since then, he is member of the Wireless, Acoustics, Environment & Expert Systems (WAVES) group, an imec research group at the Department of Information Technology (INTEC) at Ghent University. In 2011, he received his PhD on the topic of characterization and optimization of broadcast- and WLAN-networks. His current research on optimization of wireless communication and broadcast networks, focuses on coverage, radiation and interference. Also, he is involved in research on localization technologies and IoT, in the domains of industrial and health applications. Since 2016, he is part-time Professor at INTEC, Ghent University.

Eli De Poorter is Professor at IDLab, an imec research group at Ghent University. His research is on wireless communication networks for IoT applications, ranging from indoor localization to reliable communication technologies for industry 4.0. He is author of ove 100 IoT-related publications and is the coordinator of the new IoT postgraduate program at Ghent University.

Jeroen Hoebeke is Professor at the Internet Technology and Data Science Lab at Ghent University. For years, he conducts research on wireless IoT solutions. Also, he investigates open standards as a way to facilitate the implementation of sensors and actuators – and their wireless connectivity – in IoT applications. He has applied this expertise in a variety of domains, such as smart buildings, logistics, healthcare, sports and industry 4.0. Since 2015, ha also teaches the new IoT course at Ghent University.

Published on:

30 May 2018