Industrial automation is transforming manufacturing. Driven by (autonomous) robots, artificial intelligence (AI), and vast numbers of sensors interconnected via the Industrial Internet of Things (IIoT), it enhances efficiency, quality and flexibility. However, deploying these technologies on the factory floor necessitates a massive overhaul of today’s wired network infrastructure.

For the past four decades, companies have relied on robust Ethernet technology to manage industrial machinery. But while Ethernet-based networks provide ample bandwidth and speed, they come with one major drawback: with cables running everywhere, it is extremely difficult to adapt to rapidly changing customer requirements and embrace the concept of dynamic factory layouts.

So, what if we could create a deterministic wireless network tailored to Industry 4.0 use cases? A network with guaranteed, predictable performance that combines the reliability and low latency of wired networks with the flexibility of wireless solutions to minimize downtime and maximize efficiency?

The challenge: building a reliable, low-latency wireless network for flexible manufacturing

In recent years, Wi-Fi technology has become a popular choice for meeting wireless (data) communication needs in factories. Its high throughput, combined with the ease and cost-effectiveness of maintaining and reconfiguring access points, makes it an attractive deployment option. This adaptability, which Ethernet technology lacks, is especially important in flexible manufacturing environments where product types, requirements, and quantities – as well as floor layouts – change frequently.

However, there is a downside: current Wi-Fi implementations, like other wireless technologies, fall short when it comes to delivering high reliability and ultra-low latency.

“What if we could create a wireless network with guaranteed performance, combining the reliability and low latency of wired networks with the flexibility of wireless solutions, minimizing downtime and maximizing efficiency?”

The fix: an OpenWiFi-based networking stack for deterministic wireless communication

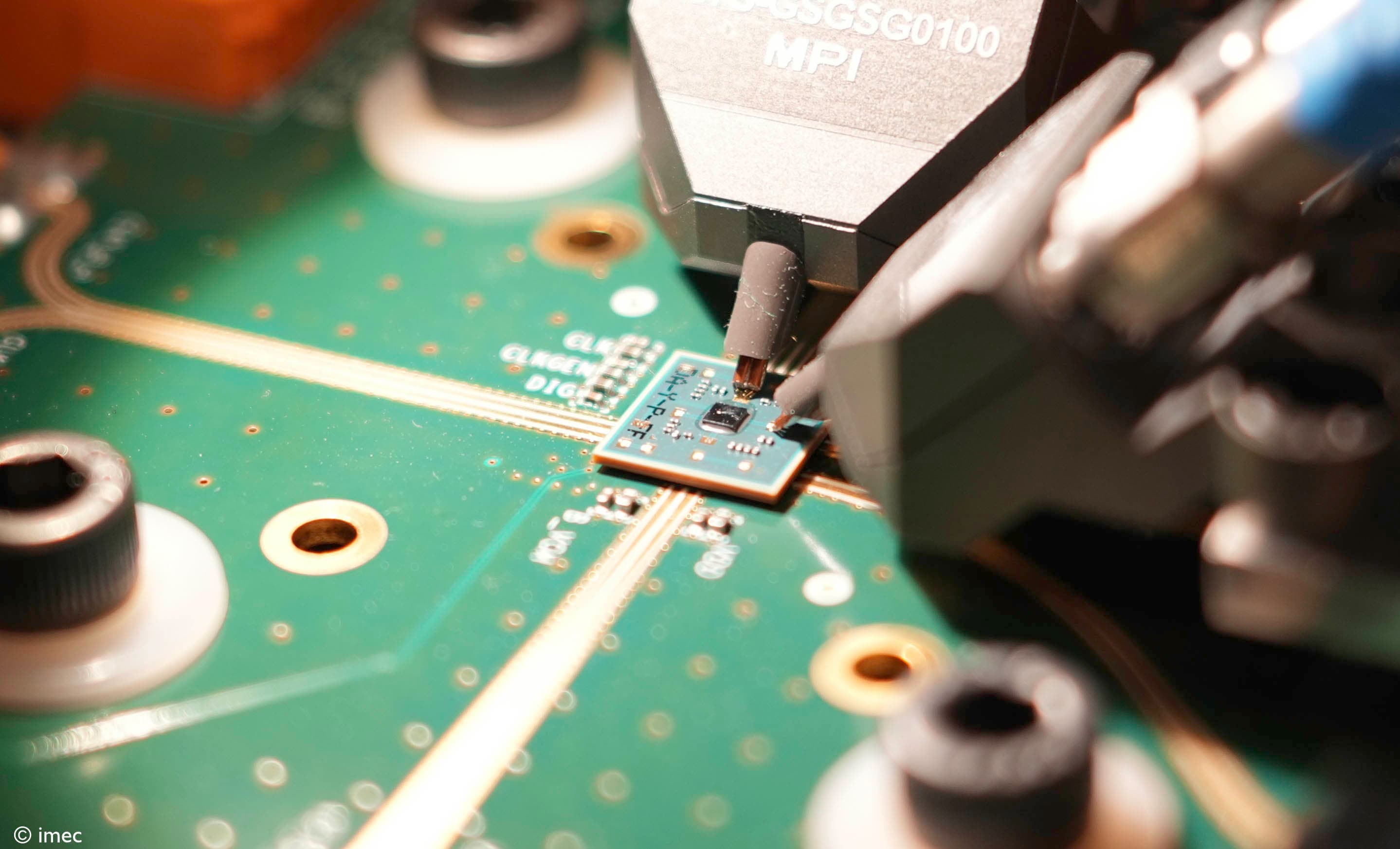

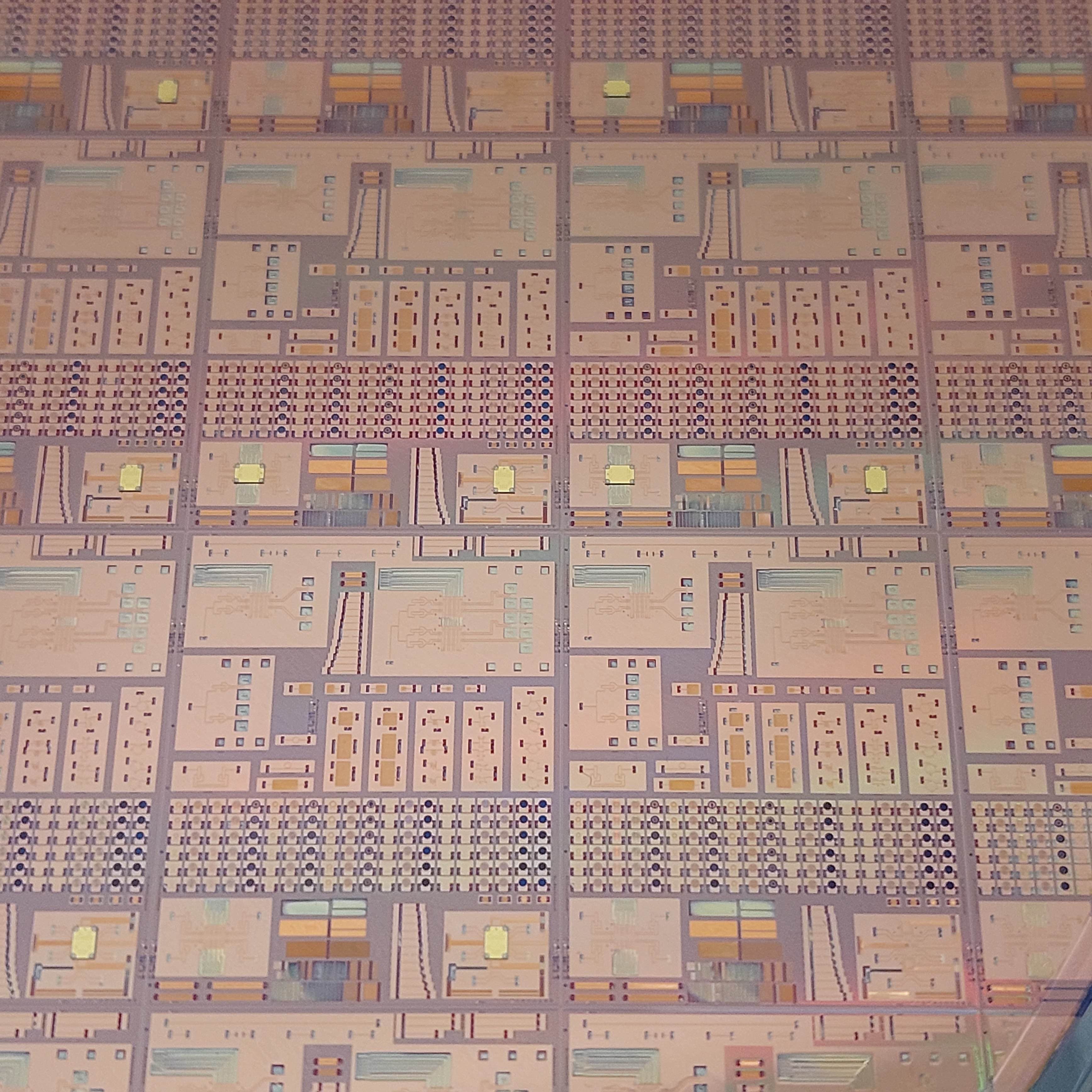

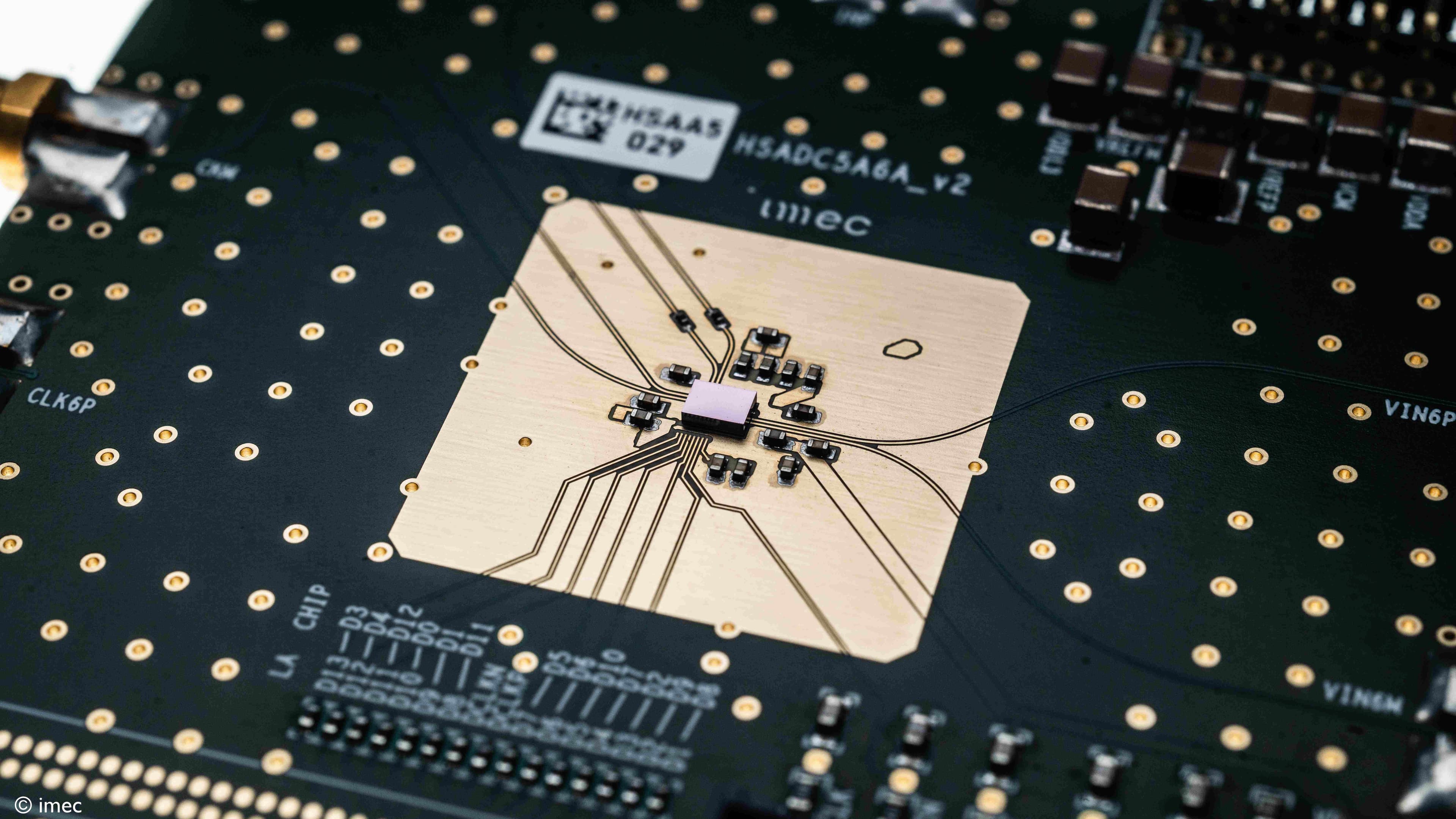

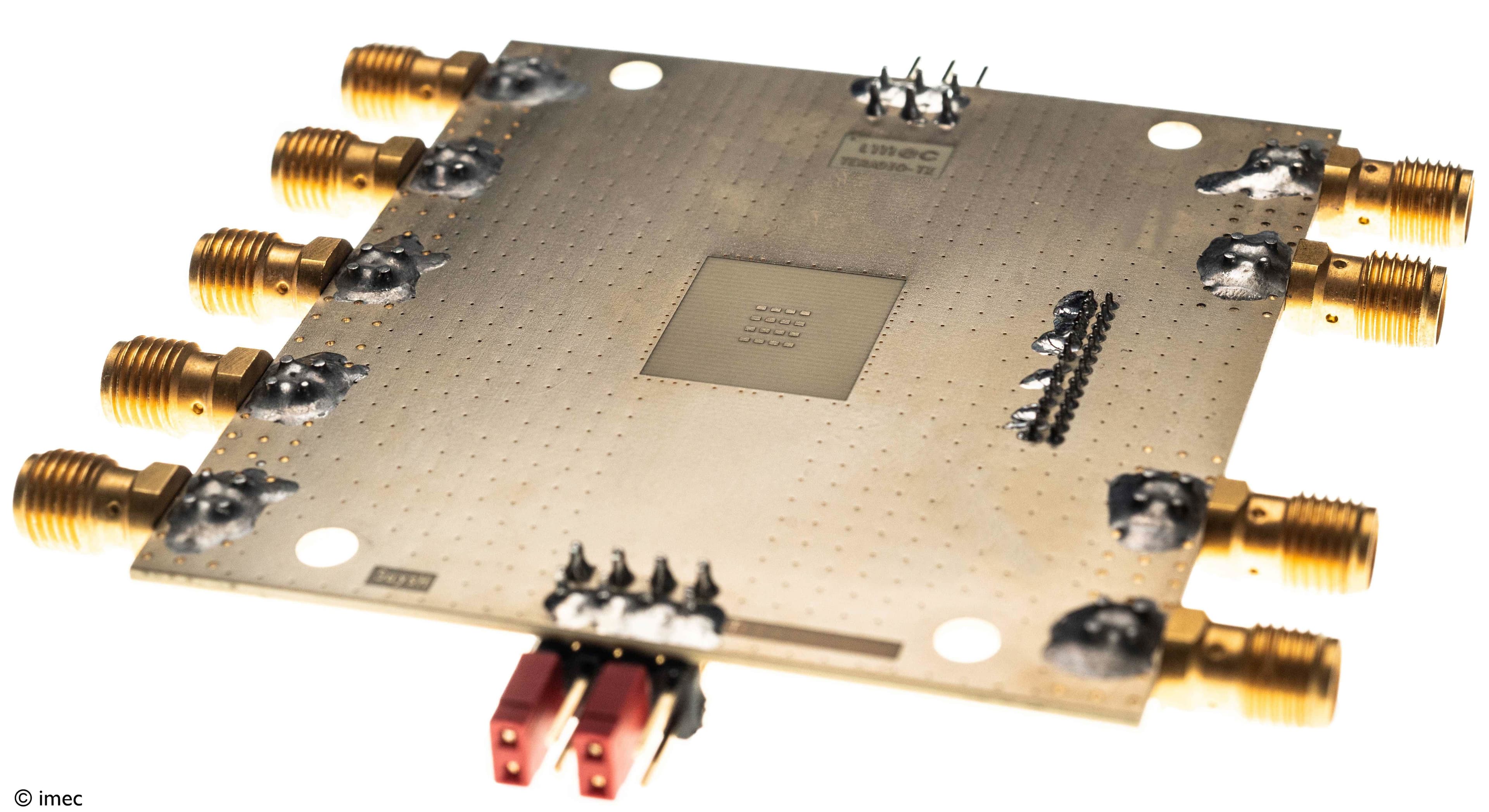

Leveraging the extensive installed base and inherent flexibility of Wi-Fi technology, researchers at IDLab (an imec research group affiliated with Ghent University and the University of Antwerp in Belgium) have developed an OpenWiFi-based application-to-physical-layer networking stack for deterministic wireless communication. Their approach supports robust operation in both ISM and licensed frequency bands and combines the reliability and low latency of wired networks with the flexibility of wireless solutions.

Detecting & avoiding external sources of interference through cutting-edge interference mitigation

What sets imec’s solution apart is its active interference mitigation capability, which significantly improves network reliability. Acting as a distributed spectrum analyzer, each wireless node can detect and avoid interference from competing technologies. This eliminates the need to manually (pre-)define frequency bands, a tedious process that must be repeated with each new installation. Instead, the devices autonomously manage interference, enabling plug-and-play deployment.

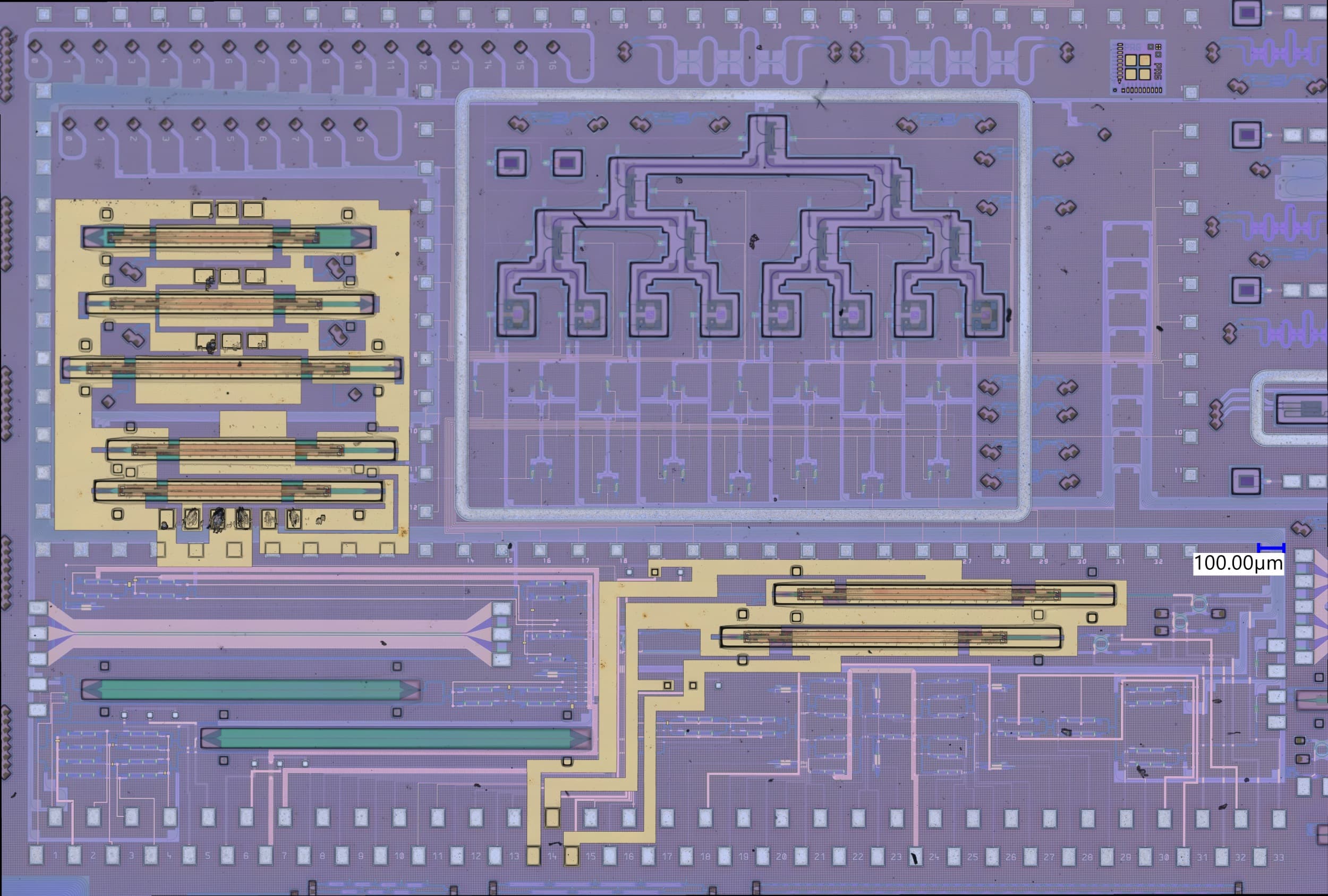

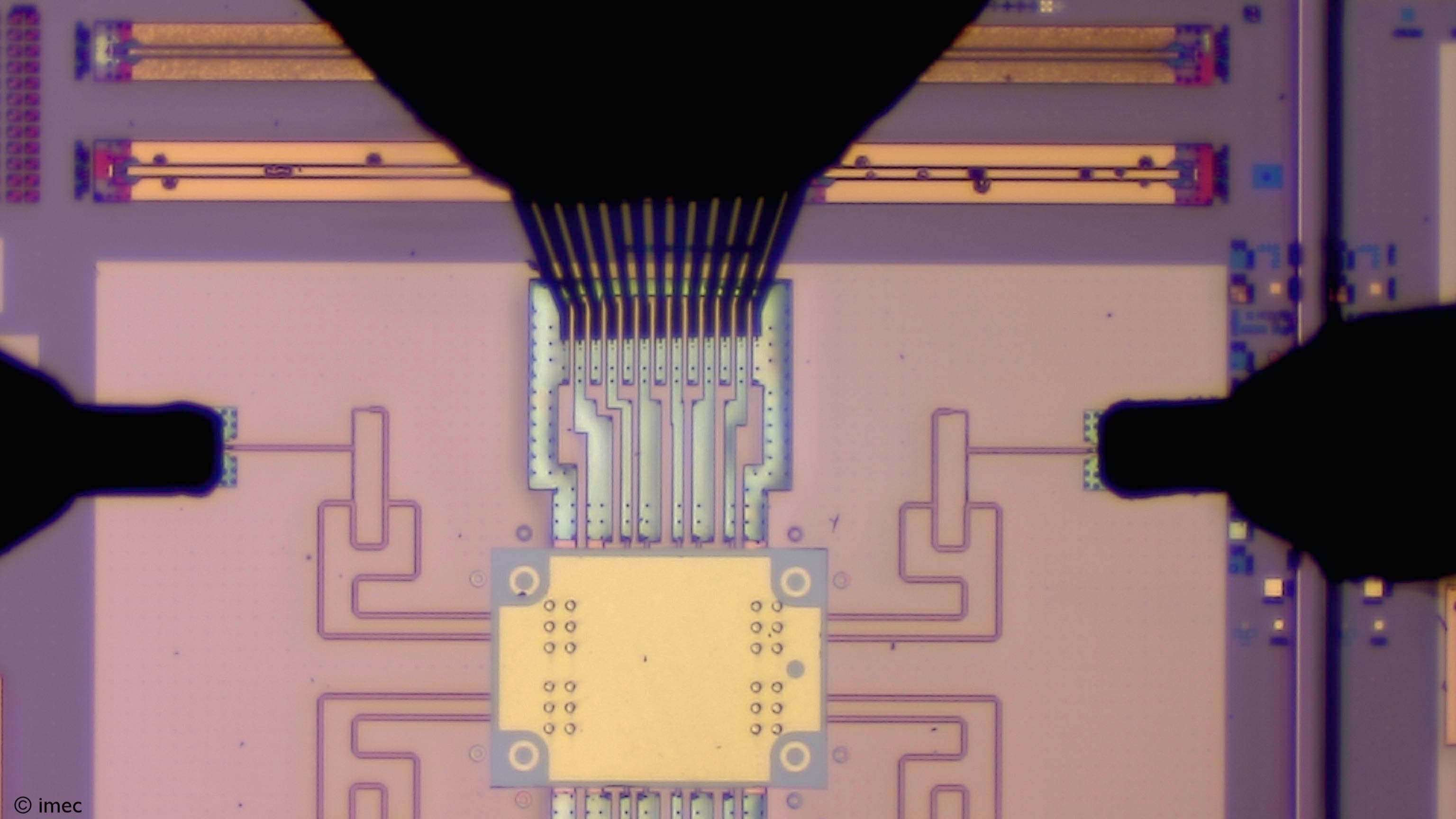

To achieve this, imec researchers have developed a custom radio with a baseband and networking stack that are completely frequency-agnostic. This allows the access nodes to independently analyze the spectrum in real time and dynamically select the optimal transmission slot within milliseconds, without any pre-planning or configuration.

Moreover, at the physical layer, the novel implementation supports 5, 10, and 20 MHz channels. While this slightly reduces network capacity, it provides greater flexibility in the frequency domain, further improving the technology’s interference mitigation capabilities.

Figure-1: The system autonomously generates a radio environment map and dynamically chooses the best transmission slot in milliseconds, eliminating the need for prior planning or configuration.

Supporting dynamic adjustments to the networking stack for guaranteed quality of service (QoS)

Another key feature is the application layer API that enables seamless communication between industrial applications and the networking stack. This allows the stack to dynamically adapt to the bandwidth, latency, and reliability requirements of each specific packet type.

For instance, if a file transfer application requires a bandwidth of 10 Mbps (and nothing else), the system will simply default to the standard 20 MHz channel width – without implementing any additional QoS measures. But if controlling a robotic arm demands ultra-low latency and high reliability, the stack will automatically reconfigure (at runtime) to meet the exact requirements of those packets.

Ensuring simplified setup, configuration, and ease of use

The architecture supports zero-touch deployment for simplified setup and configuration – and is complemented by an intuitive management platform for easy control, monitoring, and feedback.

Figure-2: The system’s intuitive management platform makes for easy monitoring and control.

To ensure an optimal user experience, the system provides real-time feedback if an application-layer flow or setting cannot be executed. For instance, if 99.9999% reliability is requested but cannot be met, the user is promptly notified and offered potential solutions. These insights are communicated instantly and do not require any special expertise on the part of the user.

The numbers: 2ms (bounded) latency and 99.999% packet success rate

The industrial automation market tends to be conservative, with companies only adopting new solutions if they don’t disrupt existing processes. For these companies, it is not the technology that matters, but the actual performance metrics.

To demonstrate the potential of their approach, imec researchers subjected it to rigorous testing in highly demanding environments. Even under difficult conditions with significant competition for bandwidth, they achieved a 99.999% packet success rate (equivalent to five nines of reliability) – and are targeting six nines in the future.

In addition, the system demonstrated an end-to-end bounded latency of 2ms, with the potential to go even lower. This is more than sufficient for most industrial automation applications, such as automated guided vehicles (AGVs), which typically operate with a (probabilistic) latency of 16ms.

Wi-Fi vs. 5G: a closer look

One question remains: should a Wi-Fi-based solution, primarily designed for indoor industrial automation, be concerned about competition from cellular / 5G deployments?

Spilios Giannoulis, a senior researcher at imec’s IDLab research group, offers his perspective: “Wi-Fi’s advantage over 5G cellular systems lies in its simplicity and cost-effectiveness. Even if you only need two nodes to cover your facility, 5G demands a more complex and expensive network infrastructure. In addition, the ongoing maintenance and licensing costs associated with 5G make Wi-Fi a more economical choice.”

“And also from a technical perspective, the Wi-Fi-based approach offers several advantages. After all, 5G’s 3GPP is still struggling to fully implement ultra-reliable low-latency communications (URLLC), a feature critical to supporting time-sensitive and mission-critical services in tomorrow's wireless factories.”

“But ultimately, what matters most is that any solution targeting the industrial automation market can seamlessly coexist with other wireless technologies, avoiding vendor or technology lock-in. This is exactly what we have achieved with our novel approach to deterministic wireless access.”

The next steps: from MVP to commercial solution

The technology developed by imec’s researchers currently exists as a minimum viable product (MVP) that has been showcased at several tradeshows and conferences.

Ongoing research is shaping it into a comprehensive commercial solution that aims to strike the optimal balance between capacity, latency and reliability when constructing datacom networks for Industry 4.0 use cases.

If you’re curious and want to explore the proof-of-concept, contact the team at https://betterthanwired.net/.

Ingrid Moerman coordinates the research activities on intelligent Wireless Networking (iWiNe) at Ghent University, leading a team of over 30 researchers. She is also the program manager of the ‘Deterministic Networking’ track within the Connectivity program at imec. In this role, she oversees research on end-to-end wired/wireless networking solutions for professional and mission-critical applications, ensuring they meet strict Quality of Service requirements in terms of throughput, bounded latency, and reliability. These applications span areas such as industrial automation, vehicular networks, safety-critical operations, and professional entertainment.

Spilios Giannoulis received his Diploma in Electrical and Computer Engineering in 2001 and his PhD in 2010, specializing in routing for wireless mobile sensor networks. From 2001 to 2015, he was a researcher at the Industrial Systems Institute and the Applied Electronics Laboratory (APEL) at the University of Patras, Greece, participating in several EU and national R&D projects. During this period, he also lectured at the Technological Educational Institute of Patras. Currently, Spilios is a senior researcher at IDLab - an imec research group at Ghent University and the University of Antwerp, Belgium - where he is involved in various EU projects focused on reconfigurable and adaptive wireless networks.

Published on:

11 February 2025