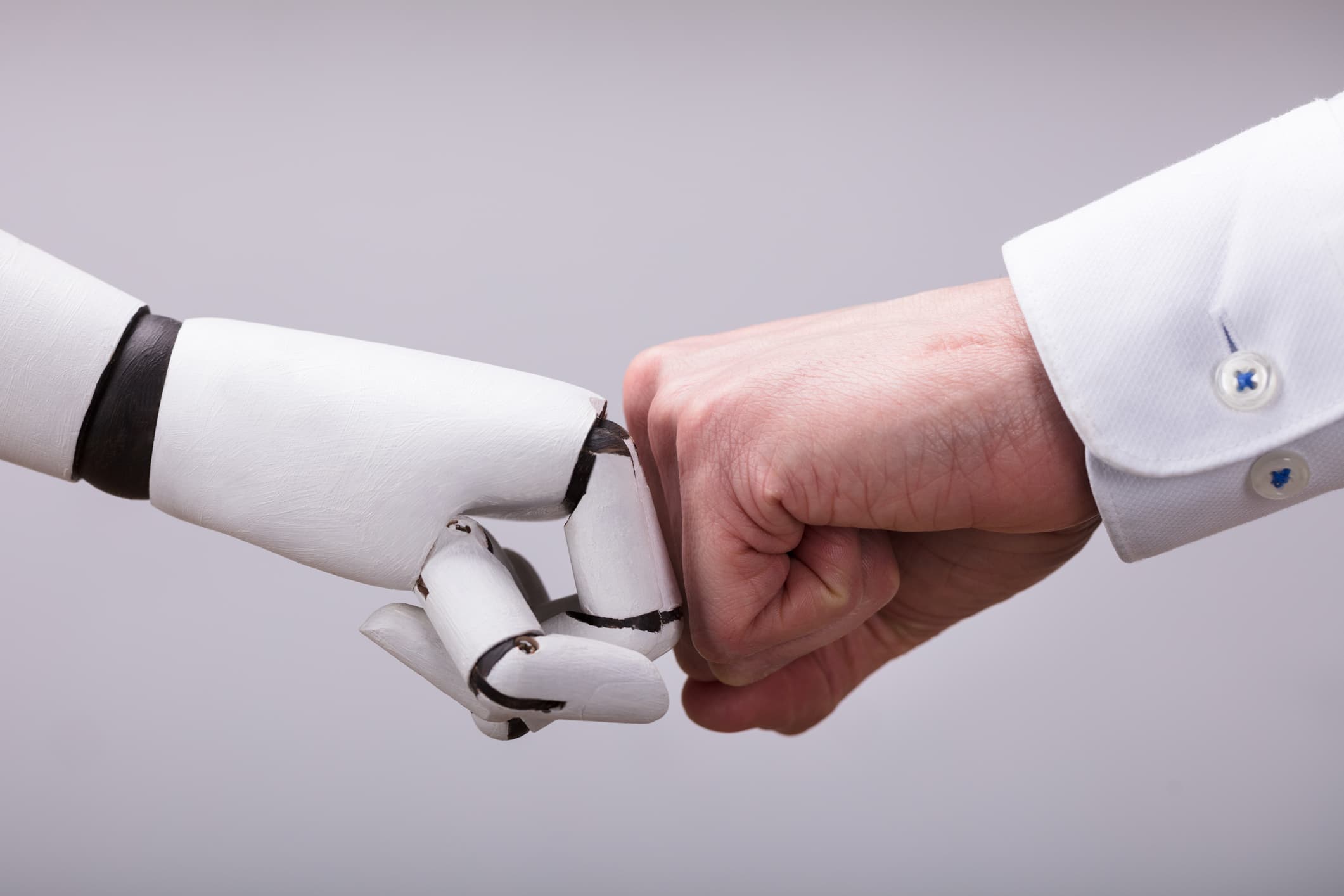

Earlier this month, the results of the imec.icon ‘ClaXon’ project were presented at Audi Brussels. The project investigated how human operators can collaborate with the newest generation of industrial robots – in a single, shared working space, without using any safety cages. First of all, a number of technical aspects were explored – such as the safety requirements that robots have to comply to in order to function among human co-workers, without giving in on robots’ accuracy. But what made this project truly unique was its focus on the human side of the story: how do people want to be supported by robots? And what would be the best way to approach this?

ClaXon research coordinator An Jacobs (imec - VUB) and her living lab colleagues Shirley Elprama en Charlotte Jewell (imec - VUB as well) spoke extensively with the operators at Audi Brussels during the past few months. In this article, we shine a light on An Jacobs’ vision on the future of industrial robotics; a future in which robots will first and foremost support human co-workers, instead of replacing them. In addition to this, Ms Jacobs addresses the question of how likely it is that our future colleagues will include humanoid robots.

Walt, the ‘cobot’, at the Audi Brussels plant

Robots have been used in all branches of heavy industry since the 1970s, such as the car manufacturing industry: everyone is familiar with images of powerful robot arms rotating from left to right and effortlessly lifting and moving the heaviest parts. It is precisely because of their strength that these robots are carefully shielded from the people in their surroundings.

But what would our factories look like if industrial robots and human operators could genuinely interact? A scenario, in other words, in which the flexibility and problem-solving capabilities of human workers would be combined with robots’ strength and precision? That was the challenge that lay at the origins of the ClaXon project.

An Jacobs: “To transform a scenario like this into reality, you would have to make use of the newest generation of industrial robots. These are actually called ‘collaborative robots’, or cobots, and are no longer confined to a steel cage.”

“In the past two years, we and our partners in the ClaXon project investigated the technical conditions that a cobot needs to comply to in order to function safely among humans – without giving in on accuracy. By equipping its rotating arms with springs we can, for example, avoid that a cobot wounds a human co-worker in case of an accidental collision. That, however, has a negative impact on the cobot’s degree of precision – which is why we developed new software that supports operators’ safety while increasing the accuracy of cobots by 60%. But combining safety with accuracy was only one aspect of the ClaXon project. Enabling new knowledge transfer approaches and new communication modalities between humans and cobots were important elements of this project as well.”

In this, An Jacobs refers to the ClaXon technology that enables operators to demonstrate a complex task – after which that task can be performed by a cobot in a flexible manner. Additionally, the project explored the use of gestures to communicate with cobots.

All of this was tested extensively in the course of a living lab research trajectory – involving genuine cobot prototypes, real-life operators and an actual production environment. The result was certainly worth it: with ‘Walt’ – a fully operational cobot – operating at the center of the Audi Brussels production floor; a cobot that efficiently collaborates with its human co-workers and receives instructions from them by means of gestures.

Industry 4.0: the social aspect

But how precisely will the use of cobots – within the broader Industry 4.0 movement – affect us in social terms? This is another question that the imec - VUB living lab researchers involved in this project tried to answer, through continuous interaction with the operators at Audi Brussels and by iteratively monitoring their expectations and concerns in the field of robotics.

“In the first place, it is important to understand that – in the past 20 or 30 years – the introduction of robots in an industrial environment has always come at the expense of jobs. Therefore, when at the start of the ClaXon project we asked the operators at Audi how they felt about robots, their initial response was: those robots are going to replace us,” explains An Jacobs. “However, we gradually saw these concerns disappear when we started to investigate, together with the operators, how machines could genuinely support them in their work. An approach like this – in which emphasis is put on ‘workable work’ and which aims at alleviating operators’ jobs instead of replacing them – was not something they had encountered before. They noticed that their opinion, their creativity, was genuinely taken into account – and that made all the difference!”

The ClaXon project thus confirms that actively involving employees, i.e. allowing them to participate, is crucial for overcoming resistance against (technological) innovation.

“As such, they actually become innovation ambassadors,” confirms An Jacobs. “Our closing interviews revealed, for example, that the Audi workers involved in the ClaXon project were extremely proud of their participation in this unique initiative.”

A humanoid as a colleague?

One of the characteristics of the ClaXon cobot is that it has a head and communicates in a ‘human’ manner with the operators – by welcoming them in the morning and addressing them by their first names, for example. This actually made ‘Walt’ a member of the team.

“This is an important lesson for future robotics projects as well. One could wonder whether equipping an industrial cobot with human characteristics is adding any value. However, this project has illustrated that it definitely makes a difference!”

Does this mean that we will see an explosion of humanoid robots, joining us as co-workers, in the next few years? According to An Jacobs chances of this happening are still rather slight: “We still have a long way to go. Also, we have to ask ourselves if we really, truly need this. Especially in industrial environments we should continue to see cobots as ‘tools’ – even though ClaXon has taught us that we must pay attention to human-robotic interaction. Yet, there is simply no distinct need to try to imitate a human being. Doing that will not bring us much – not in terms of efficiency, but also not in terms of production and employment quality.”

An Jacobs continues: “The emphasis should, first and foremost, be on the functional aspects. Consider, for example, a robot that slices bread. Of course, you can develop a robot with two perfectly shaped human hands that slices bread exactly as we would. But, do we actually need this? The cost of developing such a robot would be astronomical, and a robot might even be able to slice bread far better if we would leave the slicing method up to the robot itself. Actually, we should constantly ask ourselves questions like: what tasks are ideal for a robot? And what tasks can better be performed by people; tasks which really add value? Those are aspects to which we will have to give a great deal of thought in the coming few years. Today, robots are often one- or two-armed things devoid of any frills – just doing their jobs. Looking at it from this perspective, creating humanoid robots simply isn’t a priority.”

Is your company also trying to leverage the added value of smart industries?

Are you working with self-managing teams (teams that largely distribute their own tasks)? Collaborative robots may be the next step in the evolution of your business! An Jacobs and her colleagues are ready to explore this together with you. Get in touch with her via an.jacobs@vub.ac.be

An Jacobs has been affiliated with the imec - SMIT - VUB research group since 2005. In 2005, she defended her PhD thesis at Ghent University, which investigated the applicability of sociology in consumer goods product development. She is also the co-founder of the interdisciplinary BruBotics center at VUB.

Her scientific research within the imec - SMIT - VUB research group is directed primarily at the development of innovative applications in healthcare (coordination, communication, monitoring, perception). In this, themes such as empowerment in context-aware situations are a key element (independent living, etc.). In addition, she is committed to the further development of interdisciplinary research methods and instruments (including the living lab methodology).

Published on:

5 April 2017