Intro

Mobile networks (3G, 4G or Wi-Fi): they surround us anytime and anywhere, indoors as well as outdoors. Usually, we don’t even realize they are there – unless they’re not working (properly). Without mobile networks, we’re not able to make mobile phone calls, or stream music or video to our smartphones. And in industrial environments, they are crucial as well to ensure companies’ smooth operations (from operating and monitoring machines to sharing information).

However, despite the importance of fully operational (indoor) wireless networks, their planning and roll-out is still largely a manual exercise. Result: in some places in a building there might be no wireless coverage at all, while in other places too many signals are present – resulting in interference. Especially in harsh industrial environments (such as factories and large warehouses), the roll-out of robust and reliable wireless networks is utterly complex and challenging – as signals may get blocked by moving piles of stock and materials, resulting in loss of connectivity.

Solving Wi-Fi coverage and interference issues at ArcelorMittal, Volvo & Egemin

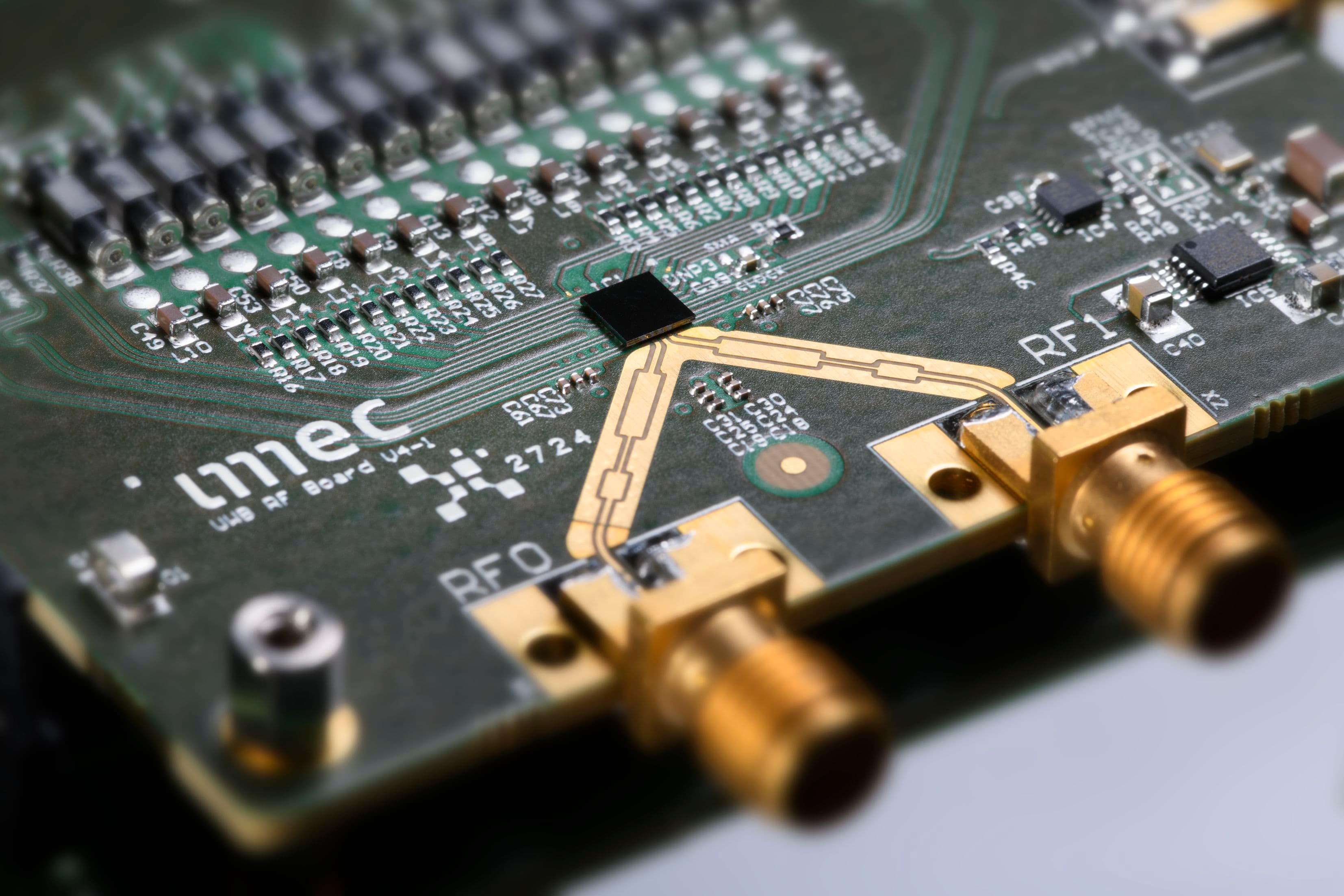

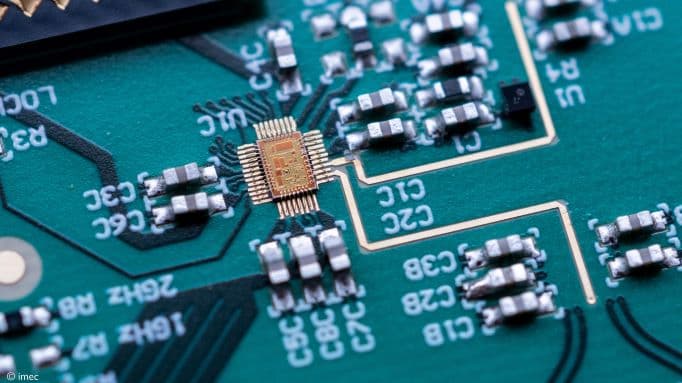

To address this challenge, in 2014, imec kicked off ‘FORWARD’, a project conducted under the umbrella of the imec.icon collaborative research program. It investigated how white spots (i.e. areas that lack wireless coverage) and sources of network interference in (industrial) buildings can be predicted more quickly, using that knowledge to automatically initiate on-the-fly network (re)configurations.

“FORWARD resulted from a very concrete and pressing need down at the production floors and warehouses of imec’s industrial partners ArcelorMittal, Volvo and Egemin,” explains David Plets from imec's WAVES research group at Ghent University. “While their range of activities is very different – from steel and car/truck manufacturing up to the delivery of automated material handling solutions for warehouses and production/distribution centers, each of them was suffering from unstable indoor wireless coverage, massive interference and hand-over issues between Wi-Fi access points.”

The Wi-Fi network that had been installed at the Volvo plant in Belgium’s city of Ghent, for instance, had difficulties adapting to the infrastructural changes that are needed to support the production of new truck models. Moreover, the presence of loads of Bluetooth devices negatively affected Wi-Fi network performance as well.

At ArcelorMittal, steel coils proved to be a major source of wireless network interference. This led to disruptions in the hand-over of the wireless signals that are used to communicate with ArcelorMittal’s moving cranes, resulting in those cranes performing emergency stops.

Lastly, Egemin wanted to investigate how its Wi-Fi network, that is used to communicate with automated guided vehicles (AGVs), can automatically reconfigure itself based on the sudden appearance of big obstacles – so that optimal network coverage (and smooth communication with the AGVs) can be provided at any time.

“Ultimately, FORWARD resulted in a number of approaches to foresee in optimal network coverage, to support a quick hand-over of traffic between (Wi-Fi) access points and to automatically (re)configure those networks on-the-fly – switching access points on/off and adapting their energy levels as is needed,” says David Plets. “Those outcomes, and more specifically the WHIPP tool we developed, now allow us to also help other partners build robust and reliable Wi-Fi networks that continue to operate flawlessly – even in harsh industrial environments.”

WHIPP: accurately predicting Wi-Fi coverage and sources of interference 10x faster

David Plets: “The use-cases at ArcelorMittal, Volvo & Egemin clearly demonstrate that sudden infrastructural changes in industrial plants and warehouses can lead to the creation of white spots. Today, those white spots are calculated through individual, manual access point measurements – a process that takes a lot of time and does not allow for quick network reconfigurations. Hence – in the framework of the FORWARD project – we developed and finetuned WHIPP, a user-friendly software tool that accurately predicts wireless coverage in homes or industrial settings for a given set of access points, based on a simple floor map.”

“Our WHIPP tool has proven to reduce the time that is needed to generate an accurate wireless coverage map by a factor of 10; an exercise that used to take three weeks with a site survey (15 working days) can now be conducted in just one day and a half.”

The WHIPP software uses a building’s (digital) construction plans as its input – while its supporting app allows to quickly and flexibly make additional access point measurements. On the one hand, WHIPP performs the actual network planning, thereby keeping the number of Wi-Fi access points (and thus the cost) as low as possible without compromising on signal quality. And on the other hand, WHIPP also calculates the total installation cost (including Ethernet and power cabling, ducts, labor costs, etc.). Moreover, the tool can be used for frequency planning (to avoid interference between Wi-Fi frequencies) and to calculate how exposure to electromagnetic radiation can be limited.

David Plets: “Existing methods to calculate the ideal configuration of indoor Wi-Fi networks have significant shortcomings. Traditional site surveys, for instance, require a lot of time and are thus very expensive. Other tools are slow, not suited to deal with large spaces, or not sufficiently accurate."

"The major advantage of WHIPP is that its underlying model has been evaluated in different environments – and has proven to keep an optimal balance between time, cost and quality-of-experience.”

Putting WHIPP to the test at a Volvo warehouse

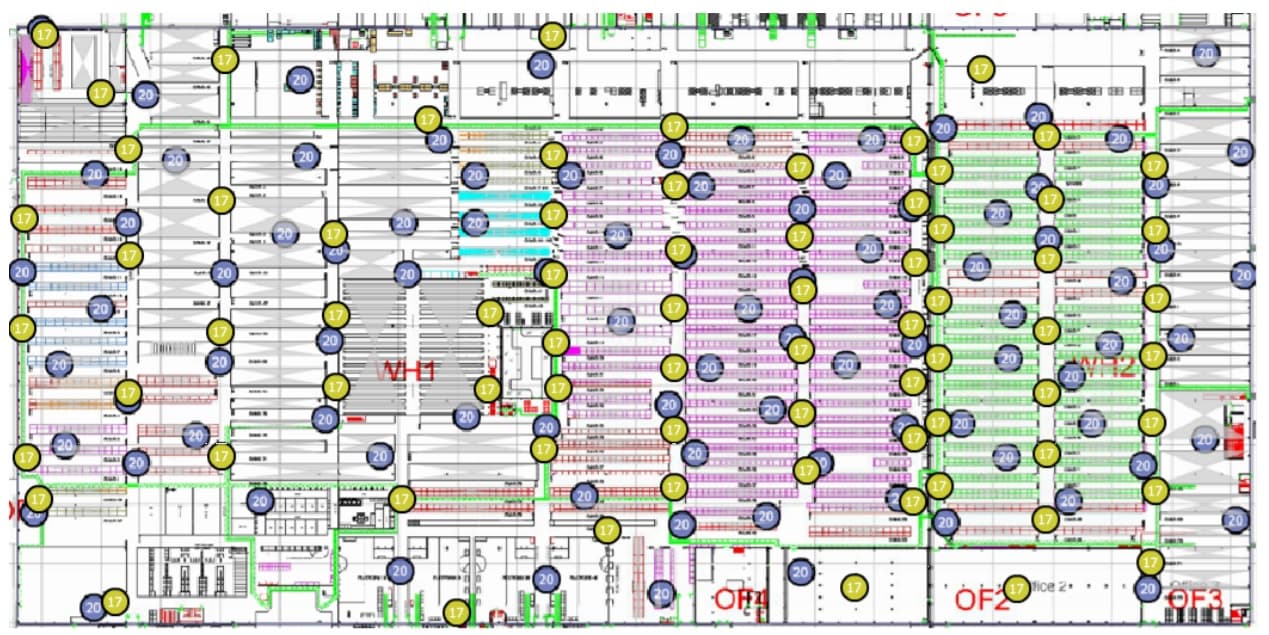

To assess WHIPP’s novel approach, a field study was set up at the Volvo premises in Ghent. It allowed the research teams to compare the results delivered by WHIPP’s automated network planning (combined with a short, one-day measurement campaign) to those of a full-blown, traditional site survey.

The study was conducted in a large Volvo factory warehouse of 415 by 200 meters, filled with 224 warehouse racks consisting of a metal frame. When filled, the racks contain wooden boxes with metal components inside. In other words: the ideal scenario to cause poor and unstable indoor Wi-Fi coverage…

When comparing the outcomes, the researchers found that both approaches yielded a comparable number – and location – of suggested Wi-Fi access points to optimize network coverage in the warehouse. The main difference, though, was to be found in the execution time (and cost): whereas the traditional site survey approach took three weeks to complete (mostly at night in order not to disturb the normal warehouse operations), only one day was required when using the automated planning tool.

This leads the imec - Ghent University researchers to conclude that – in order to obtain a fully reliable network planning at the lowest cost – it is advisable to combine WHIPP’s automated network planning with a limited validation site survey.

Map of the Volvo warehouse environment (415 m x 200 m) with indication of the network design results for automated network planning (purple-dot access points) and the site survey (yellow-dot access points). Racks are indicated as rectangular structures with a light-grey crossed area inside

How about getting your Wi-Fi network issues resolved?

Today, the WHIPP tool has been dimensioned in such a way that it can properly plan for Wi-Fi network roll-outs in any type of building – from residential buildings and factories to hospitals, event venues and opera houses.

The team of David Plets is now open to two types of collaboration activities:

“On the one hand, we have people in the field who can advise companies on how to build a stable, robust Wi-Fi network in big spaces that contain many obstacles; we equipped WHIPP with specific models to facilitate exactly that,” he says. “Alternatively, we can make the WHIPP app available to service providers – such as telecom operators – to optimize their customers’ Wi-Fi networks. Using WHIPP, we can really make poor and unstable indoor Wi-Fi coverage a relic from the past!”

Want to know more?

- Companies that are interested in leveraging this technology, can get in touch with David.Plets@ugent.be.

- About the imec.icon FORWARD project: FORWARD – a research project within the imec.icon program – was conducted by academic researchers (from imec's IDLab and WAVES research groups at Ghent University) and a number of industry partners (ArcelorMittal Ghent, Egemin, Excentis, Siemens and Volvo Group Belgium). The FORWARD project was co-financed by imec and received project support from Flanders Innovation & Entrepreneurship.

-

People wanting to read up on this topic can request following research papers by sending a mail to imecmagazine@imec.be: (1) D. Plets, W. Joseph, K. Vanhecke, E. Tanghe, and L. Martens, “Coverage Prediction and Optimization Algorithms for Indoor Environments,” EURASIP J. Wirel. Commun. Netw., vol. 1, pp. 1–23, 2012; (2) D. Plets, W. Joseph, K. Vanhecke, and L. Martens, “Exposure Optimization in Indoor Wireless Network by Heuristic Network Planning.”, Progress in Electromagnetics Research – PIER, vol. 139, pp. 445-478, 2013; (3) D. Plets, E. Tanghe, A. Paepens, L. Martens, W. Joseph, “WiFi Network Planning and Intra-Network Interference Issues in Large Industrial Warehouses”, 10th European Conference on Antennas and Propagation (Eucap 2016), Davos, Switzerland, 11-15 April 2016.

David Plets obtained a Master’s Degree in Electrotechnical Engineering in 2006. In 2011, he obtained his PhD with a dissertation on the characterization and optimization of the coverage of wireless broadcast and WLAN networks. Currently, he is a member of the WAVES research group at imec - Ghent University. His research interests include localization techniques and IoT, both for industrial and health-related applications. He is also involved in research on the optimization of (cognitive) wireless communication networks, with a focus on coverage, interference and exposure. In October 2016, he became a part-time professor in exposure to multiple physical agents in smart buildings.

Published on:

29 September 2017