The uptake of electric vehicles is expected to go hand-in-hand with the availability of solid-state batteries (i.e. batteries that contain no volatile components, and with the electrolyte having a solid form). Indeed, thanks to the development of solid-state battery technology, electric cars should be able to achieve an autonomy (driving range) matching – and eventually surpassing – that of cars with an internal combustion engine. A prototype of such vehicle will be demonstrated later this year; commercial models might be ready as soon as 2025.

Practically, a solid electrolyte allows for the integration of different active materials (such as a lithium metal anode) and cell architectures (such as bipolar arrangements), making for a higher energy density at cell and/or battery pack level. In parallel, developments such as ‘smart’ battery cells with sensors will increase the amount of usable energy in the battery pack even further.

We talked to Professor Philippe Vereecken (imec / KU Leuven / EnergyVille), who highlights the importance of these new technologies.

An electric vehicle that exceeds the driving range of a car with an internal combustion engine

Interest in electric cars is growing – not in the least because their autonomy is steadily on the rise.

However, for electric cars to really take off, they will need to match – and even exceed – the driving range of vehicles with an internal combustion engine. The key to achieving this lies in the battery itself, more specifically in the use of solid-state battery cell technology.

Today’s best-in-class lithium-ion battery (LiB) cells – containing a liquid electrolyte – have an energy density of little over 700 Watt hours per liter (Wh/l), accommodating a maximum driving range of about 500 km. Yet, wet LiB cells are gradually running out of steam: their energy density is expected to stagnate at around 800 Wh/l – due to the characteristics of their active materials.

Solid-state batteries, which contain a solid electrolyte instead of a liquid one, have the potential to achieve a higher energy density. In combination with new battery pack and battery module developments, the autonomy of electric cars could significantly be extended.

A key requirement: battery cells with an energy density of 1000 Wh/l

Today, the maximum driving range of an electric vehicle is determined by the amount of energy that is contained in the individual lithium-ion battery cells of the car’s battery pack; cells that are connected in series and parallel arrangements to provide the high currents and high voltage needed to power the electric engine.

Concretely: to achieve a driving range of 700 km, cells are required with an energy density of 1000 Wh/l (or 500 Wh/kg). Since today’s LiB cells can ‘only’ deliver 700 Wh/l (or 230 Wh/kg), a significant boost in energy density is needed.

Battery cell roadmaps foresee that cells of 1000 Wh/l should become available in 2030 – in the form of solid-state lithium-metal batteries. We will come back to the potential of those solid-state batteries immediately, but let’s first discuss an alternative approach to increase the amount of energy that can be squeezed out of an electric car’s battery pack; an approach leveraging so-called ‘smart’ battery cells.

‘Smart' battery cells: one way to extend the driving range of electric cars

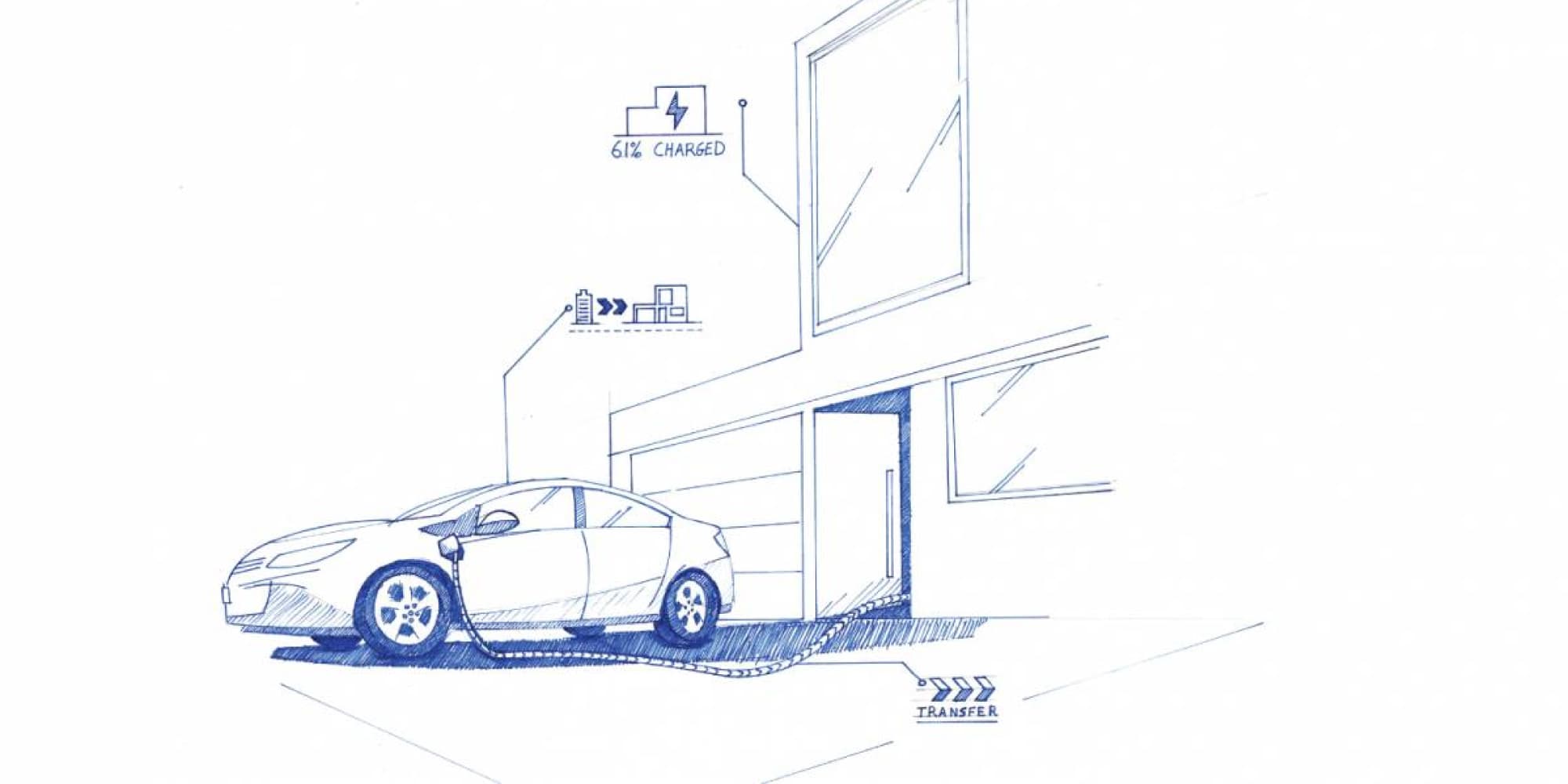

Next to the many individual cells in large battery packs, a car battery module also contains electronics and sensors to manage that battery’s usage. For example, to ensure a long (enough) lifetime, the battery management system (or BMS) will typically only use part of the cells’ energy in order to avoid damage to the cell chemistry.

In other words: the energy that can actually be used by an electric car for driving might only be 60-80% of the overall battery’s capacity (depending on the type of electric car).

Using ‘smart’ battery cells – with micro-sensors built into the cell to better monitor its state of charge and state of health – a battery’s energy management could be improved significantly. This, in turn, positively impacts electric vehicles’ driving range.

At EnergyVille – an association of the Flemish research institutes KU Leuven, VITO, imec and UHasselt in the field of sustainable energy and intelligent energy systems – research into smart battery cells with multi-array sensors and integrated electronics for communication with the BMS is currently ongoing. The first prototypes can be expected in the coming years.

Taking the next step: unlocking the potential of solid-state batteries

The first electric cars equipped with solid-state batteries are expected to get launched in the middle of the 2020’s. Toyota, for instance, has announced the presentation of a prototype at this year’s Olympic Games in Tokyo.

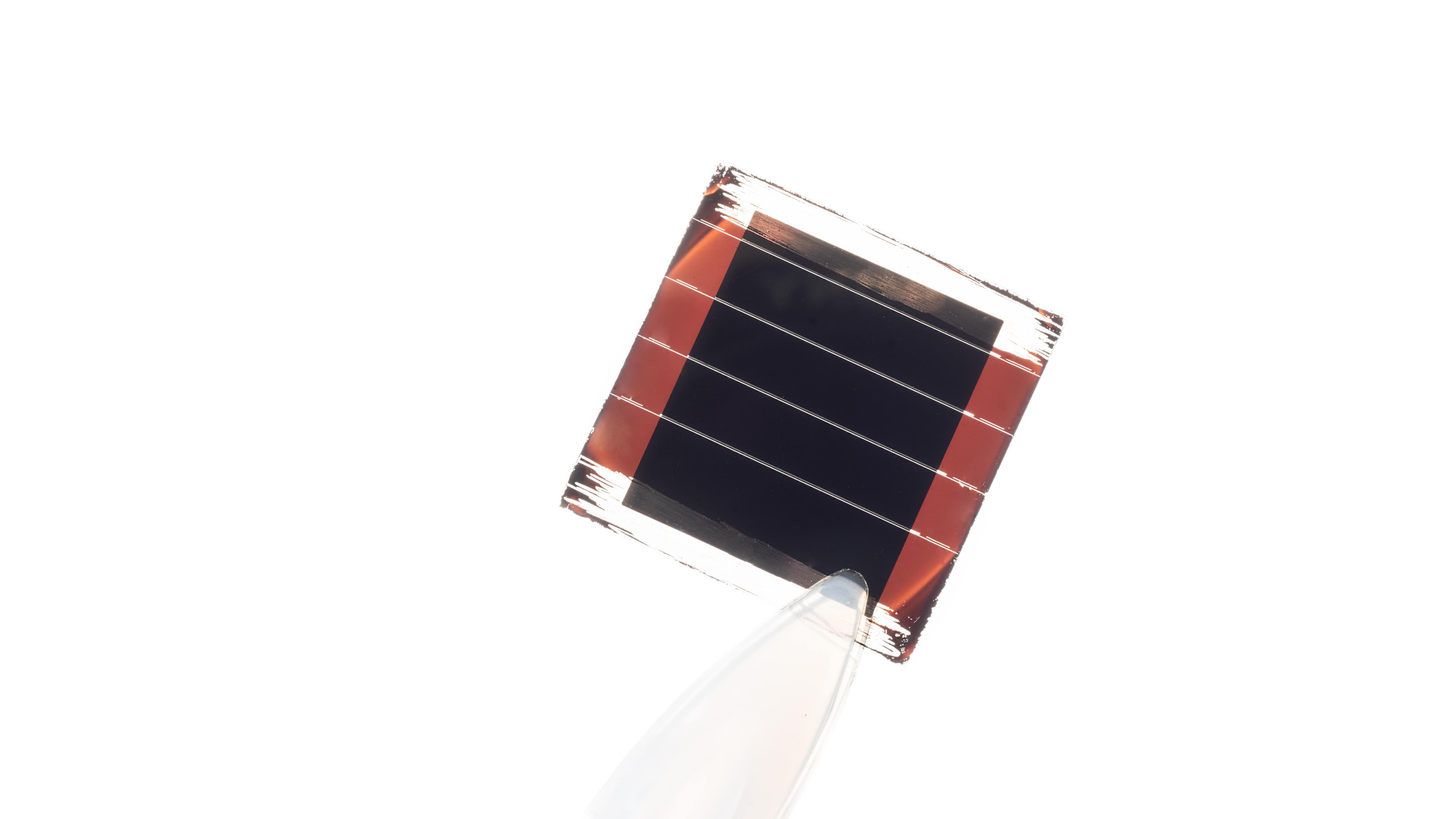

Imec's solid-state electrolyte, a new material to make next-generation LiBs for electric vehicles (artist impression). Source: imec.

That being said, the first generation(s) of solid-state LiB cells will not yet feature a higher energy density than LiBs containing a liquid electrolyte – since they will initially contain similar types of active electrode materials.

So, what’s the point of developing solid-state batteries altogether, you may ask? Well, for one, solid-state batteries allow for different, more compact arrangements in the battery pack: they can be built in bipolar arrangements providing higher voltages at cell level. This, in turn, simplifies connecting the cells and creates extra space in the battery pack to include more cells.

Solid-state LiBs will also be more intrinsically safe, meaning less safety monitoring electronics are needed in the periphery of the battery module. Finally, solid-state batteries can have a larger voltage window than wet LiBs, which means that the risk of damaging the cell during charge and discharge is reduced and a larger part of the cell energy becomes available for use.

Combining those factors, the amount of energy that is available in the battery pack will be higher for solid-state LiBs, even if the energy density of the first generation(s) of solid-state cells will be the same – or even slightly lower – than the energy density of wet LiB cells.

The energy density of the Li-ion battery (LiB) cell has more than tripled since its market introduction by Sony in 1991. Continuous improvements in LiB components with LiCoO2-graphite chemistry resulted in an average increase of 25 Wh/l per year from 1995 to 2010. Introduction of new active cathode materials, such as the NiCoAl-based and NiMnCo-based lithium metal oxides (NCA and NMC), and the gradual addition of silicon to the graphite anode have maintained the energy density increase ever since. However, it is expected that with the materials known today we will reach a practical limit for wet LiBs around 800 Wh/l. Solid-state battery technology will be needed to break through this barrier and achieve an energy density of 1000 Wh/l – and more.

In pursuit of the holy grail: solid-state lithium-metal batteries

As described above, simply replacing a liquid electrolyte in a LiB with a solid electrolyte does not make for an increase in energy density. On the contrary: inorganic solid electrolytes in powder form are likely to take up more space – and weigh more – than their liquid equivalents in current LiBs. Hence, solid electrolytes would somewhat lower the energy density of a cell with the same active electrode materials.

Schematic of a solid-state lithium-ion battery with graphite-silicon electrode and a solid-state lithium-metal battery with thin lithium metal as anode (courtesy of Xubin Chen, Philippe Vereecken, Fanny Bardé).

The real game changer lies in the fact that some solid electrolytes can provide a larger electrochemical window. In other words: they remain stable also at very high voltages (where current liquid electrolytes do not). This means that higher voltage cathode materials can be used than those in 3.6 to 3.8 Volt LiBs today; and a higher cell voltage leads to an increase in cell energy, provided the lithium-ion capacity remains the same.

For example, LiMn1.5Ni0.5O2 or LMNO has an electrode potential of 4.7 V and cannot be used with liquid electrolytes which unfortunately also react at these high voltages. Solid electrolytes such as lithium lanthanum zirconium oxide or LLZO, however, are stable up to 5V and are thus compatible with these high voltage cathodes. As such, solid-state LiBs can break the 800 Wh/l barrier.

As a next step, to reach the much desired 1000 Wh/l energy density – and to even go beyond – all-solid-state lithium-metal battery (LMB) cells are targeted, using metallic lithium as an anode. Lithium metal has the highest energy density as active anode material and also provides the highest cell voltage from the anode contribution in the cell.

So far, the use of lithium metal did not work because charging of the battery leads to the formation of lithium metal needles (or dendrites). These short the battery internally – with thermal runaway and explosions as a result. It was Dr. Akira Yoshino, one of last year’s Nobel prize winners in chemistry, who came up with graphite as a safe solution and which enabled the commercialization of the current wet LiBs in the early 90s.

Dr. Akira Yoshino - Nobel Prize in Chemistry (2019). Source: Wikipedia.

Insertion of lithium-ions in-between the layers of graphite was a safe compromise, but came at the expense of energy density and cell voltage. Several solid-state electrolytes are stable against metallic lithium and thus the use of thin lithium as an anode becomes a possibility. In fact, lithium-metal batteries with solid polymer electrolytes are already commercially available. However, these batteries only operate at temperatures of 70°C and are therefore not suitable for an electric family car. The reason for this is a too low lithium-ion conductivity for these solid polymer electrolytes. As a result, for many years, solid-state battery research has been focusing on finding solid electrolytes with a high enough ionic conductivity.

In the last few years, several good options have emerged with lithium-ion conductivities matching – or even surpassing – the ion conductivity of liquid electrolytes which are used today for lithium-ion batteries. Another contender is LLZO, a garnet-type oxidic inorganic electrolyte, which, even though its somewhat lower lithium-ion conductivity than liquid electrolytes, is of interest because of its large electrochemical window. On the downside, these inorganic electrolytes are extremely sensitive to moisture – which makes the assembly of the solid-state cells difficult (and potentially costly).

In contrast, imec has developed a nanocomposite electrolyte which is actually fabricated from liquid and turned solid once it is inside the cell. This makes the material compatible with current lithium-ion cell fabrication processes, and thus potentially low-cost.

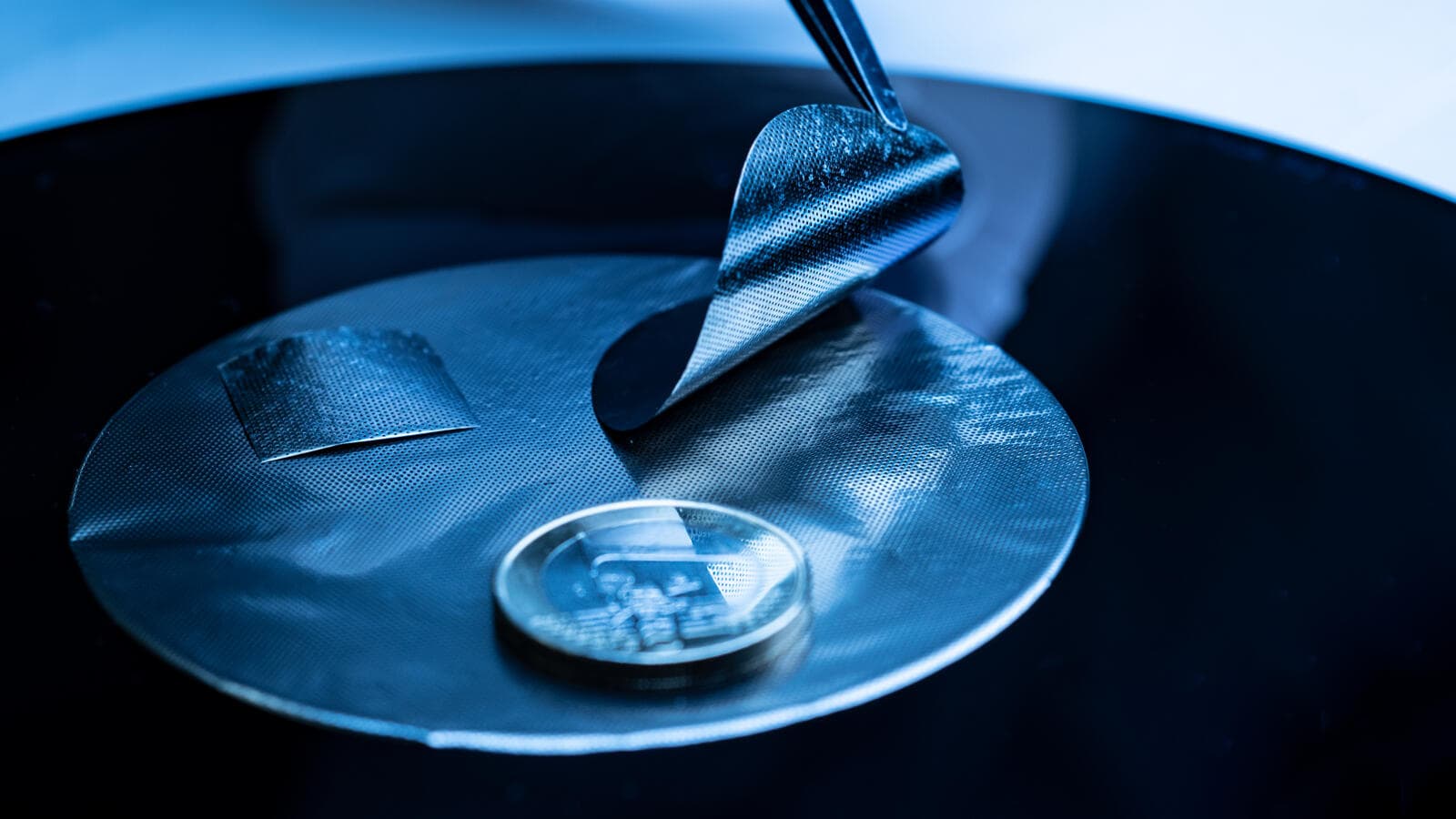

Now that several options are available, solid-state battery research has shifted its focus towards the assembly of the cells and the integration of all components into a functional cell. One of the issues is the reactivity of the materials forming resistive or blocking layers between the functional components, severely inhibiting the operation of the cell. Special thin-film coating (or so-called ‘artificial interphase coatings’) are being developed to prevent these reactions from happening.

At EnergyVille, up-scale and cost-effective methods are developed for the deposition of these sub-nanometer thin coatings inside the thick battery electrodes. These nano-scale coatings will be instrumental not only for the solid-state lithium-metal batteries under development, but also for the extendibility of LiBs with a liquid electrolyte. Indeed, much of the solid electrolyte know-how can be applied to wet LiBs as well. Who knows, the solution might be in a hybrid approach after all...

This article has previously been published as an Expert Talk at the EnergyVille blog and has been copy-edited by Wim Van Daele from imec’s News & Science Communication team.

Prof. Dr. Philippe M. Vereecken obtained a PhD in physical chemistry from Ghent University in 1998. After a stay at The Johns Hopkins University (Baltimore, USA) as a postdoctoral researcher, he worked at IBM Research (Yorktown Heights, New York) as research staff member (RSM) for several years.

In 2005, he joined imec’s nanomaterials group. In 2010, he was appointed part-time Professor at the Faculty of Bioscience Engineering, KU Leuven. That same year he kicked off imec’s energy storage activities.

Currently, Dr. Vereecken is Scientific Director Electrochemical Storage at imec. Next to the R&D on next-generation battery cell technology, his work also involves electrochemical hydrogen production and CO2 reduction.

Published on:

17 February 2020