Investigating the Reliability of Solder Balls Under Combined Impact of Thermal, Mechanical and Electromigration Stresses in Automotive Chips Using Numerical Simulations

PhD - Leuven | More than two weeks ago

Title:

Investigating the Reliability of Solder Balls Under Combined Impact of Thermal, Mechanical and Electromigration Stresses in Automotive Chips Using Numerical Simulations

Tagline:

Enhancing Reliability and Longevity of Automotive Electronics Through Advanced Simulation Techniques

Background:

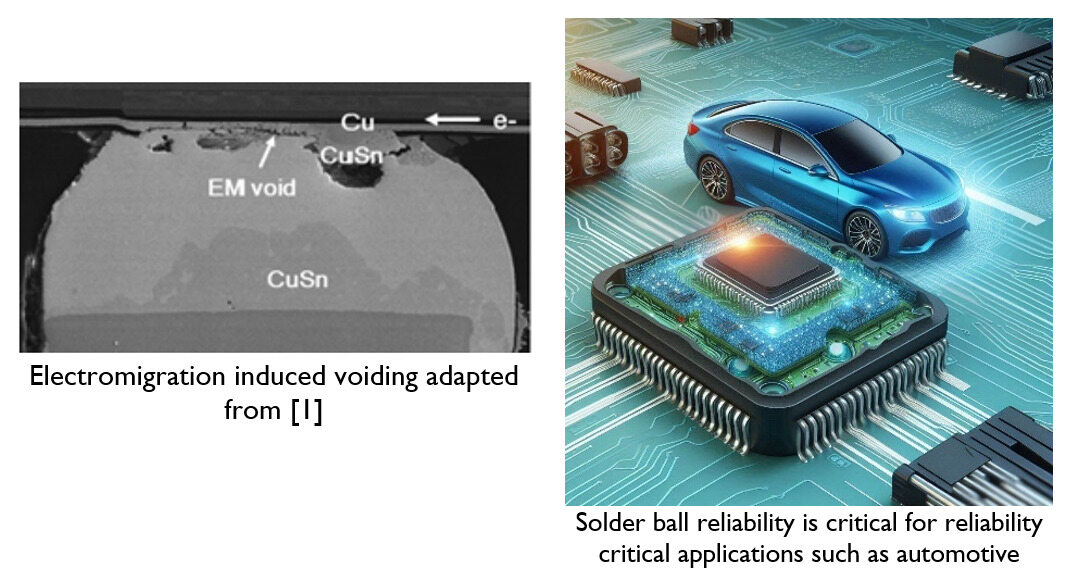

The reliability of solder joints in automotive electronics is critical due to the harsh operating environments that these components endure. Solder balls, which form the interconnections in Ball Grid Array (BGA) packages, are particularly susceptible to various aging mechanisms. These include thermal cycling, vibrations and electromigration and thermomigration, all of which can significantly impact the performance and lifespan of automotive chips.

Recent advancements in numerical simulation techniques have enabled more precise modelling of these complex interactions. By leveraging these technologies, we can gain deeper insights into the failure mechanisms of solder joints and develop strategies to mitigate them.

The existing models on solder integrity and reliability are either fully dedicated to thermal-mechanical stresses or fully dedicated to electromigration effects which result in voiding and microstructural changes of solder balls. Nevertheless, in realistic scenarios the two aging mechanisms act concurrently and degrade the integrity of solder balls synergistically.

Problem Statement:

Automotive electronics are subjected to extreme conditions that can lead to the premature failure of solder joints. The combined effects of thermal-mechanical stresses with electromigration and thermomigration, are not fully understood. This lack of understanding hampers the development of more reliable and durable electronic components.

Objectives:

The primary objectives of this research are:

- To develop numerical physics-based modelling frameworks that can capture electromigration and thermomigration induced aging in solder balls. To this end imec has a solid track record in physics-based electromigration modelling of interconnects which will be leveraged toward solder reliability.

- To couple the electromigration model with existing thermal-mechanical modeling frameworks

- To experimentally calibrate and validate the models

- To leverage the validated models towards reliability predictions for different package design parameters and operating conditions

Related reading:

[1] C. Hau-Riege and Y. Yau, "Electromigration Reliability of Solder Balls," 2018 IEEE International Symposium on the Physical and Failure Analysis of Integrated Circuits (IPFA), Singapore, 2018, pp. 1-5, doi: 10.1109/IPFA.2018.8452576.

[2] R. Labie et al., "Electromigration failure mechanisms for different flip chip bump configurations," 2011 International Reliability Physics Symposium, Monterey, CA, USA, 2011, pp. 5F.4.1-5F.4.5, doi: 10.1109/IRPS.2011.5784541.

[3] H. Ceric, H. Zahedmanesh et al.. Electromigration-induced void evolution and failure of Cu/SiCN hybrid bonds, J. Appl. Phys. 133, 105101 (2023).

[4] A. S. Saleh, K. Croes, H. Ceric, I. De Wolf, H. Zahedmanesh, A framework for combined simulations of electromigration induced stress evolution, void nucleation, and its dynamics: Application to nano-interconnect reliability, J. Appl. Phys. 134, 135102 (2023).

[5] H. Zahedmanesh 2024, Electromigration in Nano-Interconnects: Determining Reliability Margins in Redundant Mesh Networks Using a Scalable Physical–Statistical Hybrid Paradigm, Micromachines 2024, 15(8), 956; https://doi.org/10.3390/mi15080956.

Required background: engineering science, engineering technology, computer science, or equivalent

Type of work: 10% literature and technological study, 70% to develop efficient computational models, 20% to design and conduct experiments to calibrate and validate the computational models.

Supervisor: Houman Zahedmanesh

Daily advisor: Houman Zahedmanesh, Riet Labie

The reference code for this position is 2025-008. Mention this reference code on your application form.