MonIEflex

Steering industrial manufacturers’ power consumption in function of fluctuating green energy supplies

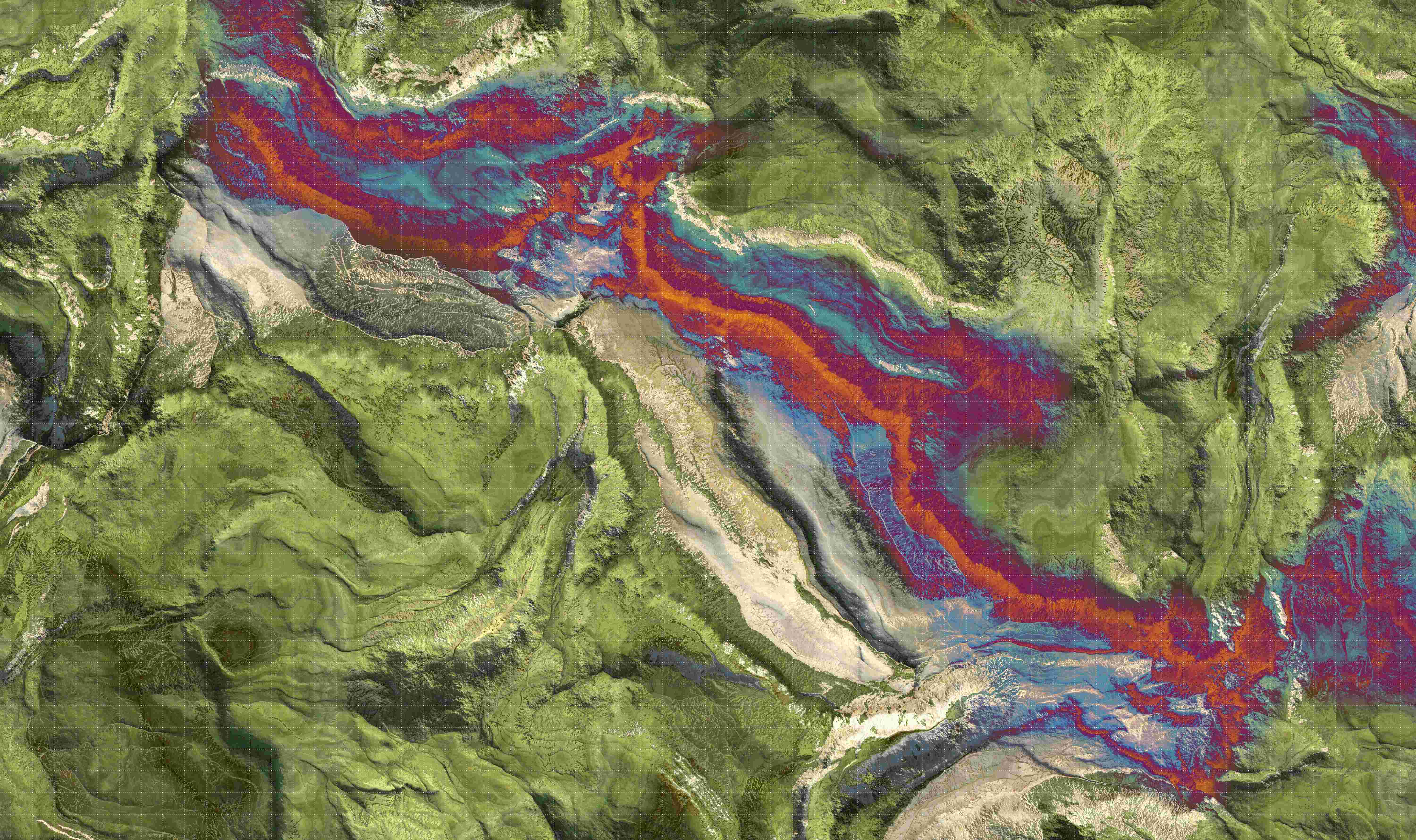

The threat of global warming, rapid depletion of natural resources such as oil, coal and gas, and recent issues with nuclear power plants have significantly raised political and societal interest in the use of green, renewable energy sources.

Yet, green energy comes with an unpredictable and intermittent output. Therefore, the need increases for software that is capable of steering power demand of commercial and industrial consumers quickly and automatically – to match supply of intermittent green energy, yet without disrupting their operations.

“To deal with imbalances between energy production and energy consumption, grid operators have traditionally been looking at approaches that create flexibility on the supply side,” says Matthias Strobbe (iMinds - Ghent University). “Concretely, fast-reacting power plants (typically running on natural gas) are activated during periods of peak consumption. But that’s a highly expensive and polluting method.”

“Putting the Industry 4.0 and smart grid concepts center stage, the MonIEflex project took a completely different approach,” adds Thomas Zeebergh (Siemens). “We wanted to define, design and assess new software components that allow us to identify and free up ‘flexible capacity’ at large industrial power consumers – in a non-intrusive way.”

Project outcomes

- An award-winning, non-intrusive ‘flexible capacity’ estimation engine

- A proof-of-concept that covers the whole value chain – from collecting sensor info, to data aggregation, decision-making and business case modelling

- A new service that has already been commercialized in Belgium and the UK

MonIEflex Leaflet

MonIEflex

Steering industrial manufacturers’ power consumption in function of fluctuating green energy supplies

MonIEflex (Optimizing Monetization of Industrial Energy flexibility) is an imec.icon research project funded by imec.

It ran from 01.01.2014 until 31.12.2015.

Project information

Industry

- Siemens

Research

- imec - IBCN - UGent

- imec - DistriNet - KU Leuven

- imec - SMIT - VUB

Contact

- Project Lead: Lieven Kenis

- Research Lead: Matthias Strobbe

- Innovation Manager: Stefan Van Baelen