The same technology, but much easier to use

Most of the fluid sensors used today are expensive (costing anything from a few hundred euro and up to a thousand), relatively large and often still manufactured by hand to measure just one specific parameter. “We have made a miniature version of this fluid sensor,” explains Zevenbergen. “We use the same technology – ion-sensitive electrodes – but by applying our expertise in chip technology, we are able to make the system much smaller. In fact, we can place a range of electrodes on an area of about 1 cm². We can also use it to measure the pH and salt concentration of a solution. An essential component is the reference electrode, which is also incorporated into this small area. Moreover, where there is a particular application that also needs to measure, say, the temperature, it’s easy to add a temperature sensor. Finally, the sensor also has readout electronics and a radio device for transmitting the data wirelessly. So, in fact, it’s a sort of miniature box of building blocks to which you can add the bricks that you need. And because the system is based on chip technology, it’s all very compact and inexpensive.”

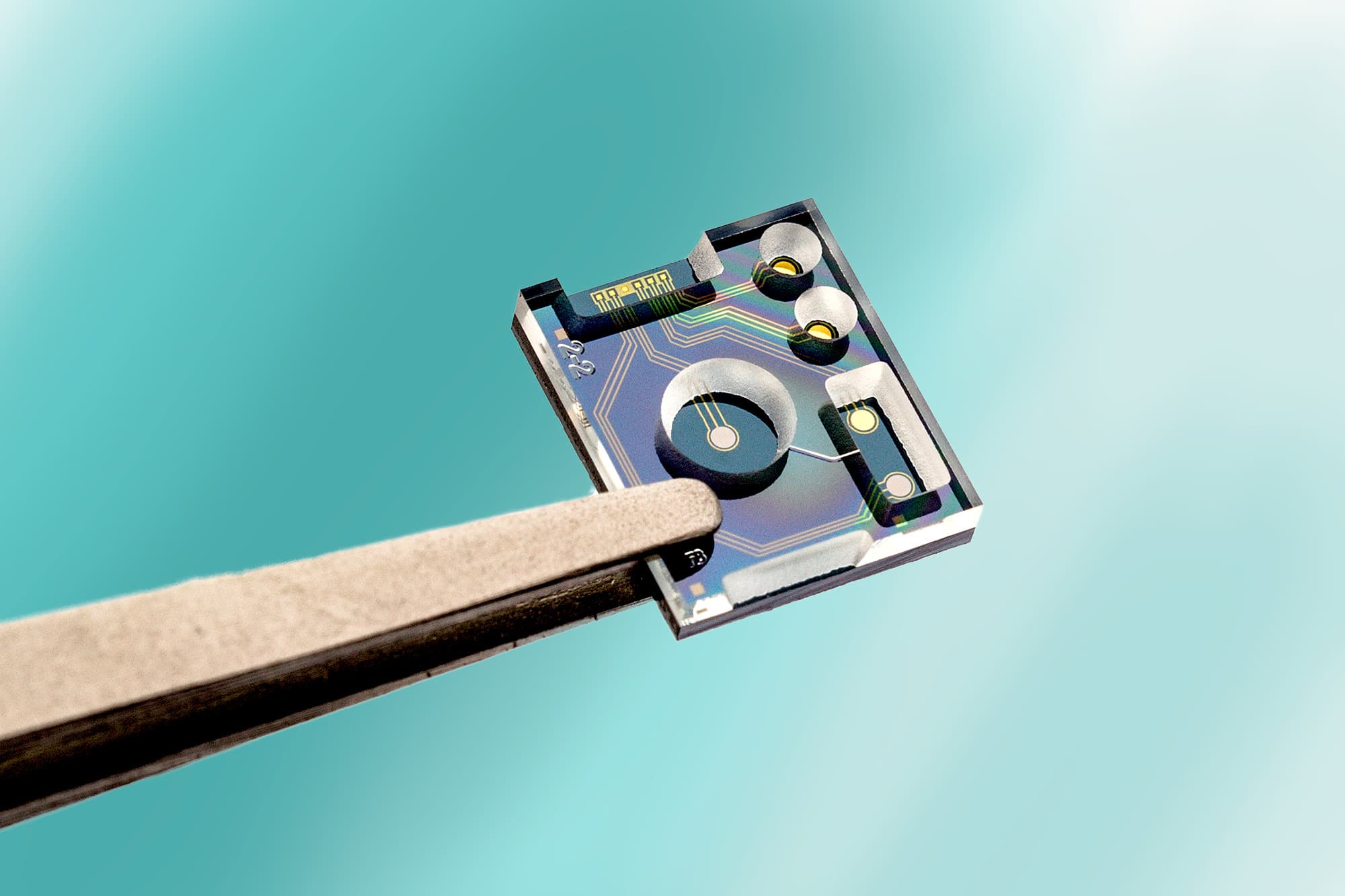

Design of the fluid sensor, in this case with two ion-sensitive electrodes (IrOx for pH and Ag/AgCl for Cl) on a silicon substrate. The reference electrode is an Ag/AgCl electrode that is placed in a tank containing a known solution. Microfluidic channels provide the contact with the fluid to be examined (to close the electrical circuit). Because this channel is so small, none of the reference fluid leaks away and so the reference electrode is extremely stable.

The fluid sensor can be produced on silicon, as well as on flexible film. This latter application is of interest if the sensor is to be applied to a curved surface, such as in a smart plaster that analyzes sweat. Each electrode can be treated with a different surface chemical to make it sensitive to other ions. Marcel Zevenbergen: “We are currently developing dispensing techniques for applying this surface chemistry automatically. We are also converting machines that are now being used to glue epoxy for this purpose.”

Properties of imec’s fluid sensor and some of the ions that can be measured with it.

There are two versions of the fluid sensor: one on silicon and the other on a bendable substrate.

These small and inexpensive fluid sensors, which can also communicate with each other and the outside world, can be used in applications such as the Internet-of-Things. Let’s look at some of these applications.

A fluid sensor for every river

It was on 10 July in Diksmuide, at the nearby Blankaart nature reserve, that the first fluid sensor measuring pH, temperature and salt concentration was launched for a research project established in conjunction with VITO, De Watergroep, Aquafin and Vlakwa. Marcel Zevenbergen: “Our aim is to have around 100 sensors deployed in the reserve within 18 months. The ultimate goal is to be able to use this kind of sensor network to monitor the quality of subsoil water, groundwater and surface water, as well as treated sewage water, continuously and in real-time. This will enable us to make better use of our available water reserves, based on demand. This particular project is designed to test how closely we need to position the sensors to each other, as well as to see if they are sufficiently stable to work properly in this environment, etc.”

The idyllic landscape of the De Blankaart nature reserve was the setting for the first tests using the new fluid sensor to provide continuous, real-time measurements of the water quality. (Copyright Yves Adams – Vilda)

Sweat is the new blood

Imec/Holst Centre is developing a ‘sweat patch’ as part of the European Nexgen project. The patch is a kind of minilab that you wear on your skin (as you would a sticking plaster) to analyze your sweat. The already mentioned fluid sensor forms the heart of this smart patch. “The composition of your sweat enables us to detect various diseases (such as cystic fibrosis), as well as the extent of dehydration in sportsmen or the elderly, plus potassium levels in marathon runners and so on,” explains Marcel Zevenbergen. “The advantage that sweat has over blood is that it can be monitored in a far less invasive way. I am convinced that analyzing sweat will become an important way to monitor our health in the future. One indicator of this is the many start-ups that have been created in recent years and which produce this kind of application. Analysts predict that the worldwide market for smart patches such as the sweat patch will grow by more than 88% between 2016 and 2020.”

The sweat patch developed by imec and Holst Centre contains a series of AgCl electrodes and a reference electrode. In the Nexgen project, this plaster is being developed further into a stable, easy-to-use prototype.

Teaching tomato plants to talk

Fluid sensors are also ideal for use in agriculture and horticulture. Examples include the hydroculture of lettuce or other crops and how these sensors can provide highly localized information about the composition of the feedwater being used. “This way, farmers can have their own ‘control room’, with screens providing a clear visual display of areas that have problems with nutrients or too little water, so that they know where action is needed,” says Marcel Zevenbergen. “It also means that disease can be nipped in the bud, as it were. In the GROW! project we are working with the Agricultural Test Center in Hoogstraten to test the fluid sensor in this context. It measures the nutrients in each plant that are exchanged with the water via the roots. The same thing applies to lettuce and crops grown under hydroculture conditions. We are also working on visualizing the data and the way it is processed and interpreted so that the grower can take properly informed decisions.”

Bioreactors: from yoghurt to cell therapy

Fluid sensors can do valuable work in all of the applications in which bioreactors are used. This includes brewing beer, producing yoghurt, making wine and even cultivating modified cells for cell therapy. Marcel Zevenbergen: “We have already talked with a number of breweries about this. In large breweries, the fermentation process is monitored so closely that the sensor may not make such a big difference, but for smaller brewing operations or when starting up a new product, it can certainly be of value for keeping a constant, real-time eye on the composition of the solution in the bioreactor. It can also definitely make a difference for cell therapy, because there you are using a material that varies a great deal – the cells of a specific patient – which may react very differently to the same culture conditions. Now it’s a question of contacting the right companies that can use their expertise to say how the fluid sensor can best be used.”

Personalized dialysis

Kidney dialysis is a highly invasive treatment: patients have to be hooked up to a dialysis machine for 3 hours, three times a week. And after these dialysis sessions they usually feel even worse and more tired than when they started – a feeling known as the ‘dialysis hangover’. This happens because dialysis is only able to approximate the natural kidney function. Our kidneys work 24/7, but because dialysis concentrates the purification process into 3 x 4 hours a week, the body has to deal with major fluctuations in its water balance and so there is a major likelihood of its sodium, potassium and calcium balance being upset.

“Dialysis removes the toxins from the body, but at the same time it has an effect on important electrolytes such as sodium, potassium and calcium, which can lead to fluctuations in blood pressure (sodium), short-term arrhythmia (potassium) and osteoporosis in the long term (calcium). The optimum settings for these precious electrolytes also vary from patient to patient, whereas current treatment has to be a “one-size-fits-all” compromise,” stresses Marcel Zevenbergen.

“If you can accurately measure how much of the body’s salts a person flushes away or adds naturally, you might be able to personalize dialysis. That’s why we are researching to see whether our fluid sensors can be used in wearable, compact kidney dialysis equipment, such as the wearable artificial kidney that the Dutch Kidney Foundation is working on.”

Imec collaborates with the Dutch Kidney Foundation on this topic, and both are member of the American FDA and the American Society of Nephrology, enabling stakeholders worldwide to work together on establishing an international innovation roadmap for kidney replacement therapies. This roadmap is being drawn in conjunction with patient organizations, with the Kidney Foundation and imec playing a leading role. This KHI Renal Replacement Roadmap was presented internationally in Seattle on 20-21 August.

Organs on chip: do the cells feel at home?

Scientists all over the world – including at imec – are investigating the possibility of growing heart and brain cells, etc. on a chip. The function of the chip is to send signals to the cells and also scan signals sent out by the cells. This would provide a way of testing and developing therapeutic drugs more quickly.

“In this context it is also interesting to add ion-sensitive electrodes to the chip, more specifically in the mini-spaces that the cells grow in,” explains Marcel Zevenbergen. “That’s because it is important to monitor the growth medium used for the cells closely so that they can be kept alive for as long as possible. The composition of the solution also provides an idea of the quality of the cells, indicating whether they are growing in the same way as they do inside the body. This last point is important if you want to carry out relevant tests.”

A ‘pleasant’ bowel examination

Somewhere in the distant future, the aim is to develop sensors that you can swallow like a pill and which carry out examinations in the intestines. This type of smart pill can also contain fluid sensors. Marcel Zevenbergen: “If we can miniaturize our technology even further, it can certainly be used in this type of application. In fact, part of the diagnosis will consist of checking the pH of the environment, or determining the concentration of certain ions. And all of this information can help the doctor to find out what is going on with the patient.”

For companies

All of this means that there are plenty of potential applications for the new fluid sensor – anywhere you want to measure the composition of a fluid, continuously and in real-time, in fact. In the short term, the sensor can be used in watercourses and greenhouses, whereas the longer term promises applications such as organs-on-chip and smart pills. “We are now looking for companies that want to use this technology in their products, or to optimize their production processes, or else to use it in unique applications such as horticulture, healthcare, the food industry or water collection. We have already developed a demo kit for these businesses so that they can experiment and find out for themselves what this technology is capable of.”

Demo kit with fluid sensor available for companies to use for testing.

Want to know more?

- Use this contact form to request the IEDM paper about the fluid sensor. The paper contains more technical details about the structure of the sensor. Note that in the meantime – the paper dates from 2016 – the sensor has been made even smaller.

- You can request a paper about a patch capable of measuring the composition of sweat – based on the fluid sensor in this article – using this contact form.

- Holst Centre was founded in 2005 by imec and TNO. It is an independent research center located in Eindhoven that works with industry to develop innovative applications related to wireless sensors and flexible electronics. More information: www.holstcentre.com

- Want to find out more about the sweat plaster developed in the Nexgen project? Then be sure to take a look at the project website

- More information about the GROW project (only available in Dutch): https://has.nl/nl/project-grow

- Read about heart cells-on-chip in our June issue.

Marcel Zevenbergen obtained a MSc from Delft University of Technology in 2005 and a PhD from the same university in 2009. During his PhD, he developed a sensor capable of electrically detecting single molecules in solution. Afterwards, he joined imec in the Netherlands where his main interests include the development of novel sensor platforms for the applications mentioned in this article. In his current role as program manager, he investigates how these sensors can be used to solve various challenges in liquid sensing.

Published on:

31 August 2018