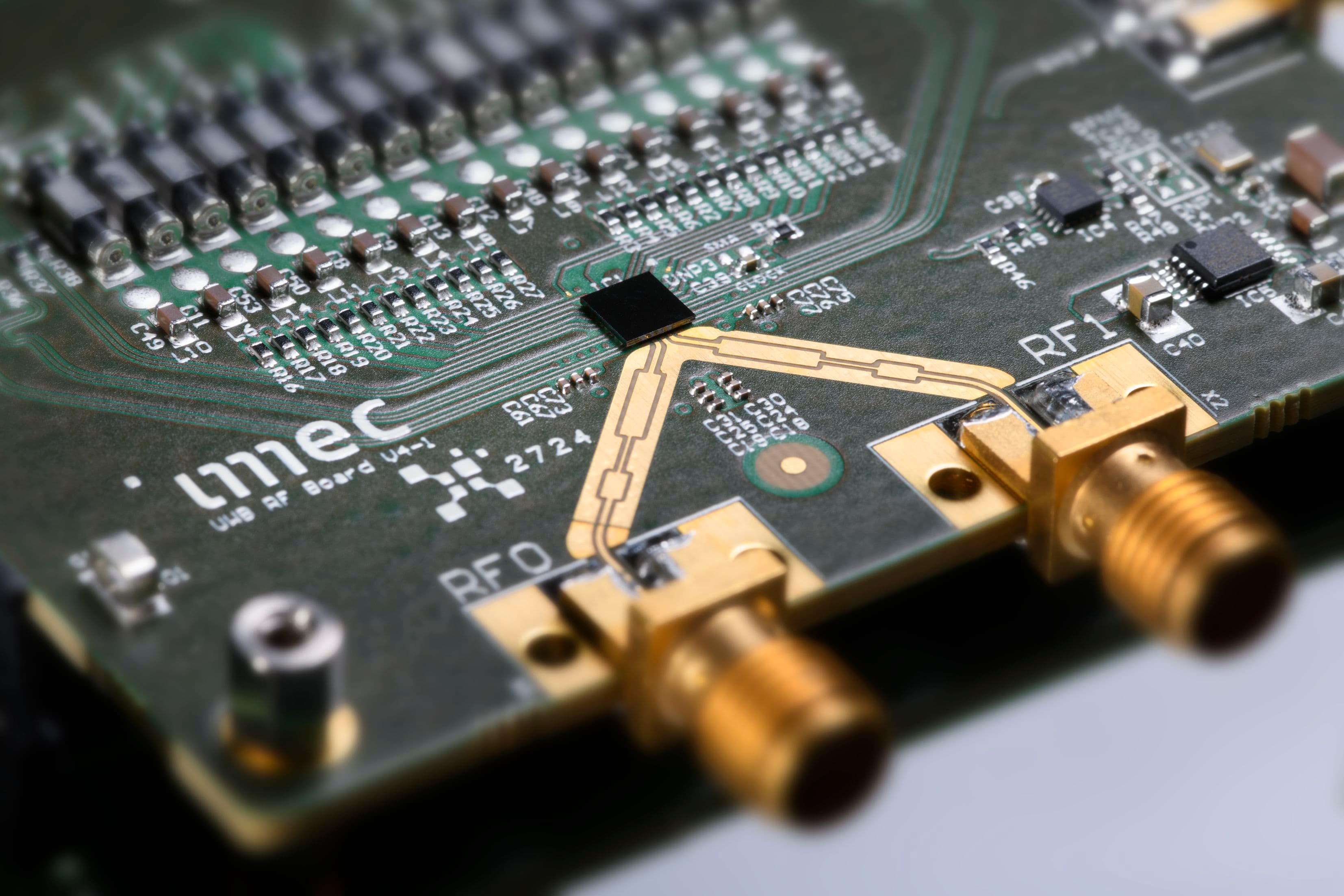

The new SoC has now been presented twice: once at the renowned ISSCC conference to the research community, while at the more public-oriented Consumer Electronics Show (CES), a medical plaster was presented as a demo platform for the chip.

Nick Van Helleputte, R&D Manager Biomedical Circuits and Systems at imec, tells us why it is important to convince chip manufacturers who are interested to produce the SoC. It’s because this SoC will enable producers of a new generation of wearables to make truly unique products. In fact, thanks to the new chip, the products can be made up to 10 times more cheaply and/or much smaller so that they are even more comfortable for the patient.

All-in-one and very economical

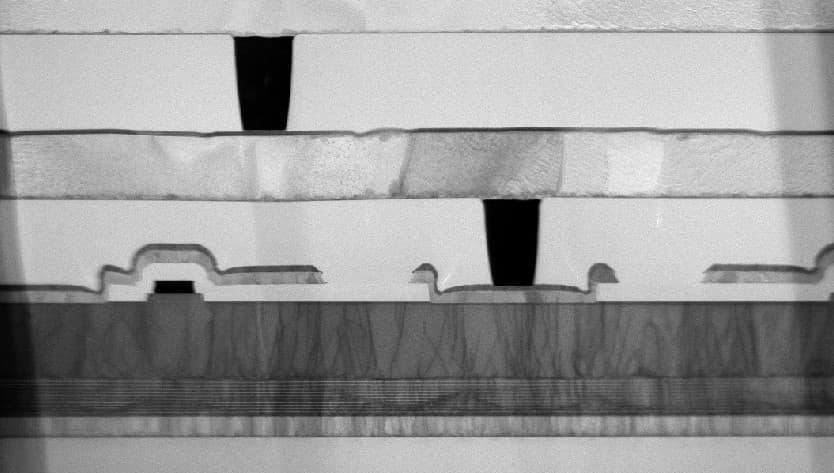

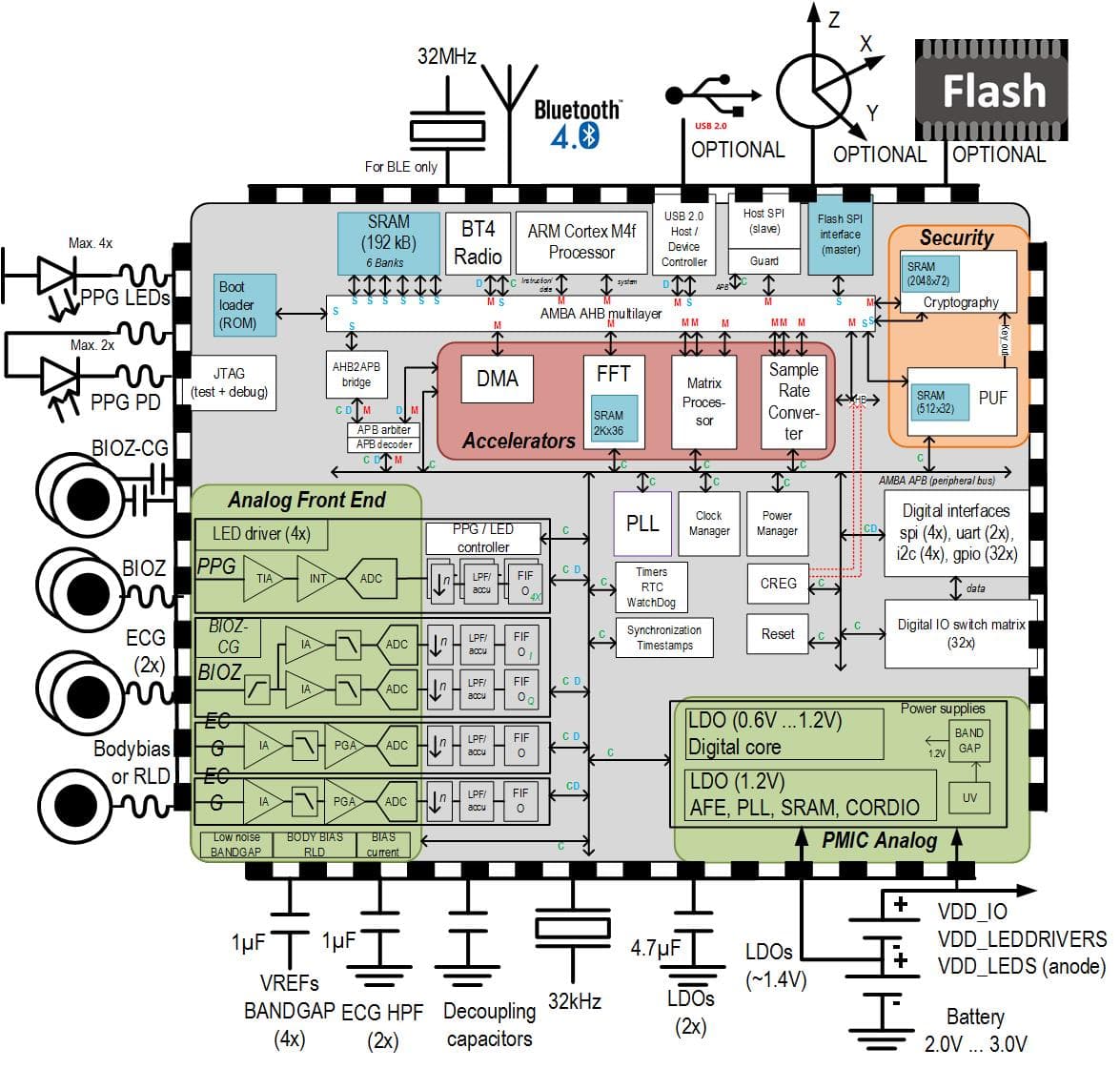

The third generation of the MUSEIC chip, as it has been named by researchers, contains the building blocks that are normally present as separate chips in today’s wearables (such as Fitbit, Bloomlife, QardioCore and so on). By combining all of the specially designed and optimized building blocks on a single chip, it creates a more powerful, economical and smaller system.

The SoC also features a high-performance analog front-end, which is unique because it is able to read out (and synchronize) several health parameters at the same time. It has been chosen for two electrocardiogram channels (ECG) and two photoplethysmogram channels (PPG). There is also a multi-frequency bio-impedance-channel (BIO-Z). In fact, the modular SoC design means that it is simple to design alternative versions of the chip. Adding a core body temperature feature in the future is also being considered.

Typically, the design has been for analog front-ends in older chip technologies, because these have a better noise, matching and leakage current performance than the newer technology generations. Yet, to enable co-integration of the front end with digital and RF blocks, the option has been taken here for the newer 55 nm chip technology, which has good results for noise, matching and leakage current.

The chip also features a digital signal processor, cryptography IP block and various interfaces, such as a BLE radio and USB2 interface. Two low dropout regulators (LDO) use a battery (1.3 to 2.0 V) to create a configurable voltage for the digital core and a fixed voltage for the SRAM, BLE, AFE (active front end) and on-chip PLL (phase locked loop).

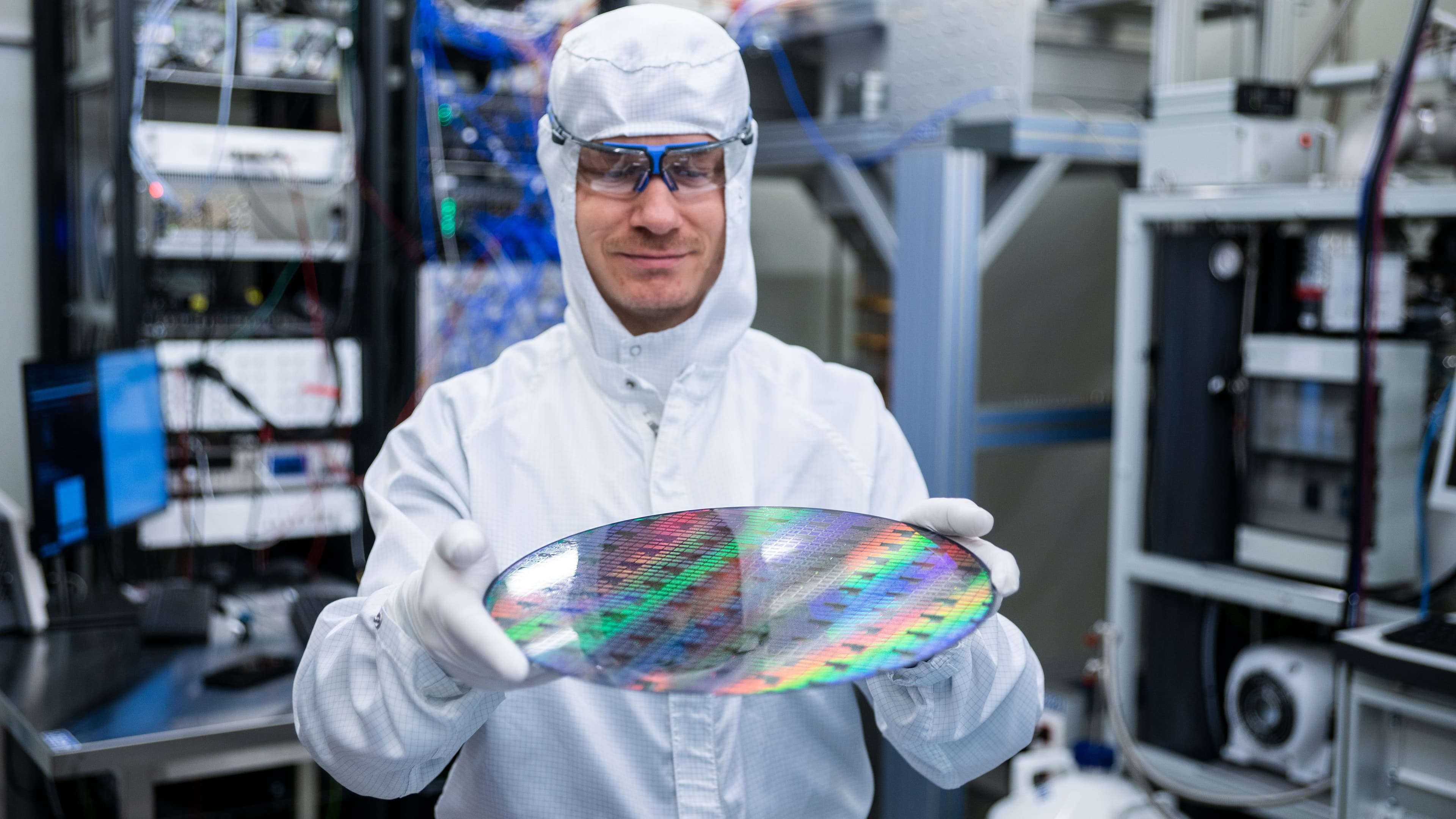

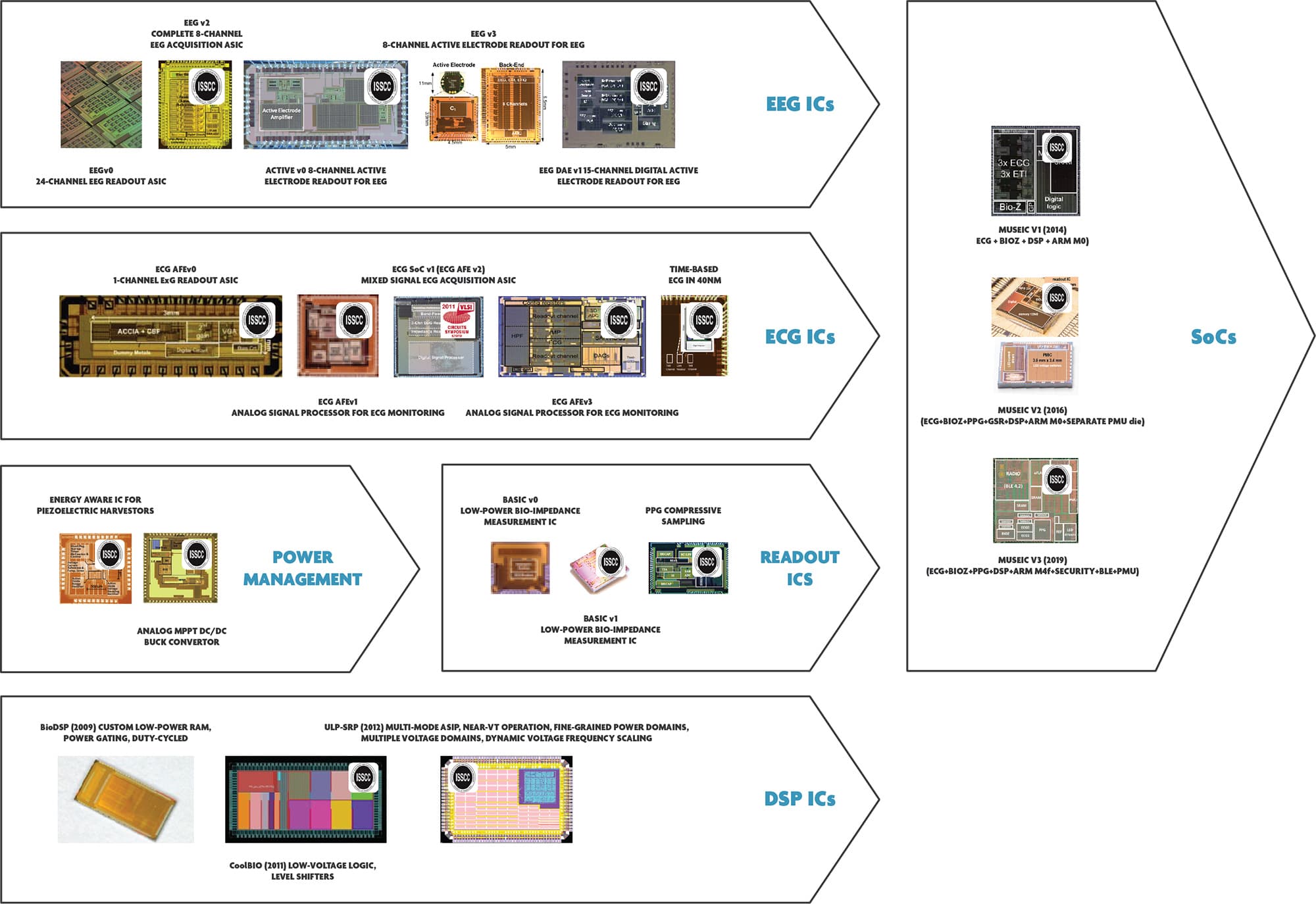

Imec is strongly committed to chip design and the tape out of these chips so that they can be tested in prototypes. Researchers are testing the latest technologies and designs to be able to produce the chips more economically, more efficiently and cheaper, which in turn will make new products possible. Here is a summary of imec’s track record in chips for medical wearables.

Imec’s MUSEIC chip contains all of the components required for a medical wearable, such as an analog front end for different parameters, a microprocessor, cryptography and an interface for BLE and USB2. Thanks to the power management circuit, the chip can operate for up to 3 weeks, using a power source such as a ZnAir battery.

A new generation of wearables for doctors

Today, patients whose blood pressure or ECG readings need to be monitored for an extended period are sent home with expensive equipment that is usually fairly bulky as well. This equipment then has to be returned to the doctor afterwards and also needs preparing for the next patient by medical staff (recharging, disinfecting, etc.). It is this cumbersome process that makes wearables for home monitoring of little attraction for hospitals.

But using a new generation of wearables is likely to make this situation change. So, imagine you’re prescribed a wearable by the doctor; you go and pick it up from the pharmacy and, after using it, you can throw it away (after sending in the data using your mobile phone) – just like a pregnancy test. This scenario becomes possible when cheap, environmentally friendly materials are used and inexpensive chips take the readings and do the processing.

The heart plaster as an example

At the Holst Centre in the Netherlands, imec is developing wearables to take readings of the body’s parameters. These include things such as an EEG headset to measure brain activity, a watch for monitoring stress, or a plaster for heart and lung activity.

These prototypes are not yet intended for production and use by consumers. However, clinical researchers can use them in areas such as eating disorders and anxiety, depression, autism, etc.

Imec takes great interest in receiving feedback from these clinical researchers about the usage and quality of the parameters measured, as well as which parameters still need to be developed and so on. Through these parallel developments, technological building blocks can be developed that are of genuine value when to comes to companies turning them into products for the marketplace.

In addition to their use in clinical research, wearables also make the ideal demo platform for illustrating the unique properties of the chips used in them.

The latest wearable to come out of imec’s close collaboration with TNO at the Holst Centre is a heart plaster. This is a waterproof plaster made from very thin, pliable and elastic TPU material. The dry electrodes and connections are made from printed electronics. And at the core of the plaster is the SoC described above.

Patients are able to take readings of the following indicators for seven days: oxygen saturation in the blood (SpO2), exercise (using the accelerometer), heart activity (ECG) and bioelectrical impedance. The first of these parameters – SpO2 – is vital for quantifying the physical health of the patient, given that low SpO2 levels can indicate hypoxemia. If hypoxemia is not treated in time, organ functions may be affected and the person may even go into respiratory and cardiac arrest.

This heart plaster is a demonstration platform for the MUSEIC SoC produced by imec. Through cooperation with various hospitals, prototypes such as these are also used for clinical research. Feedback from clinical researchers means that the chip is constantly being improved.

Want to know more?

- Our colleague, Mario Konijnenburg, describes the MUSEIC chip in greater detail in an ISSCC paper. If you would like to receive a copy of this paper, you can request it via our contact form.

- You can download the technical leaflet about the MUSEIC chip here.

- Imec and Holst Centre published this press release about the heart plaster presented at CES.

Nick Van Helleputte received his MSc degree in electrical engineering in 2004 from the Katholieke Universiteit Leuven, Belgium. He received his PhD from the same university in 2009 (KU Leuven MICAS research group). His PhD research focused on low-power ultra-wide-band analog front-end receivers for a wide range of applications. He joined imec in 2009 as an Analog R&D Design Engineer. He is currently R&D manager of the connected health solutions team. His research focus is on ultra-low-power circuits for biomedical applications. He has been involved in analog and mixed-signal ASIC design for wearable and implantable healthcare solutions. Nick is an IEEE member and served on the technical program committee of VLSI circuits symposium and ISSCC.

Published on:

1 March 2019