In a truly interconnected world, microchips will not only be embedded in vehicles, household appliances and health wearables, but also in cheaper consumer goods. Smart labels – integrated into products’ packaging, for example – could be used to track items from production till consumption, providing detailed information on a product’s freshness, origin, or preparation instructions. By combining the plastic RFID chips developed by imec and TNO in the frame of Holst Centre with cost-efficient, screen-printed antennas, smart labels may soon become reality. To explore this opportunity, imec has teamed up with Quad Industries and Agfa; a collaboration that resulted in a security badge application that combines plastic RFID tags with screen-printed antennas, both in the tags themselves and in the reader.

Imec: the perks of plastic RFID chips

Imec has been exploring the domain of plastic electronics for more than a decade and launched the first plastic microprocessor in 2012. And just last year, imec and Holst Centre received the “Best Product” Award at the Printed Electronics Europe Conference for a joint project with Cartamundi, a manufacturer of board games and playing cards that specializes in giving regular games a digital edge. Together, they developed a set of playing cards with integrated plastic RFID chips (with regular, commercial antennas), combining the joy of a traditional card game with the thrill of a computer game.

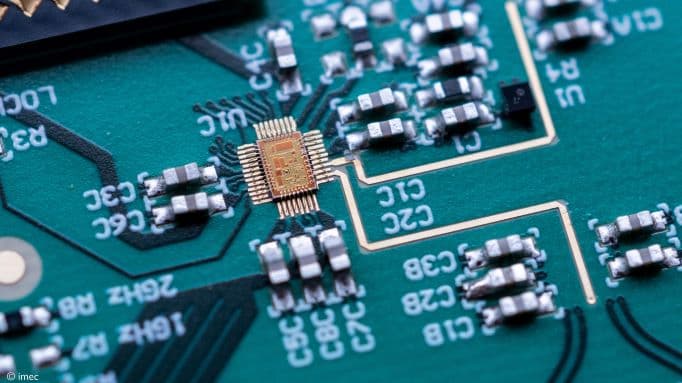

RFID (Radio Frequency Identification)-chips allow close-range communication with a dedicated read-out system. Traditional RFID chips are based on silicon CMOS technology, but imec’s plastic chips use thin-film transistor (TFT) technologies instead. The semiconductor, a thin film of metal-oxides (a blend of indium-gallium-zinc-oxide) has a low temperature budget enabling direct deposition on plastic foil, thus resulting in flexible chip technology.

This plastic technology offers significant advantages. Kris Myny (principal member of technical staff - imec) explains: “Because our plastic chips are ultrathin and flexible, they can be invisibly integrated into virtually any product. You can wrap them around your wrist, fold them, or bend them any way you want.” This flexibility makes it possible to include electronics in products that could never be technologically enhanced before. For instance, the plastic tags could be integrated in paper packaging for food, in security documents or even in banknotes. Because the tags are so thin, they can really disappear into the product’s design.

From a commercial point of view, the main advantage of these thin-film microchips is cost-efficiency. Kris Myny: “When introduced in large scale foundry manufacturing, plastic chips have a unique cost advantage. This is because of the technological simplicity. Only a limited number of steps are needed to produce these plastic circuits. When mass produced, we see our chips evolving towards the cost of less than 1 eurocent. That’s about ten to hundred times cheaper than what you have on the market today. Such an ambitious scaling plan would of course require a strong ‘application pull’”, so we are working closely with application companies to define a vision on how this new technology can grow.”

Quad Industries: printed electronics today

Quad Industries specializes in printed electronics on different substrates, ranging from plastic to textile or even paper. Wim Christiaens (R&D Director, Quad Industries) explains: “The main advantages of printed electronics are that it’s cost-competitive and allows for direct integration of electronics in any material. Additive processing makes the production process faster and cheaper, and offers a revolutionary path to make any object smart.”

Today, Quad Industries still mainly makes use of silicon chips. Combining its technology with imec’s plastic chips would not only reduce costs even further, but would also open up new application opportunities because of the enhanced flexibility.

Security badge application: plastic RFID tags with screen-printed antennas

In 2015, a consortium of Flemish companies coordinated by Agfa started a new SIM-SOPPOM[1] project, i.e. Met@link. The project aims to use printed metallic inks for conductive functionalities to enhance the technological and economic feasibility of the Internet of Things and hybrid flexible electronics. The project partners recently demonstrated an application example of such technology, i.e. an access control system. The access badge contains one of imec’s plastic RFID tags in combination with a screen-printed antenna. Screen-printed antennas have been successfully implemented on top of RFID tags before, but this time, the RFID reader also contains a screen-printed antenna. Previously, the reader always used a standard printed circuit board (PCB) antenna. Using a flexible screen-printed antenna instead allows optimal integration of the reader, even on curved or 3D shaped surfaces.

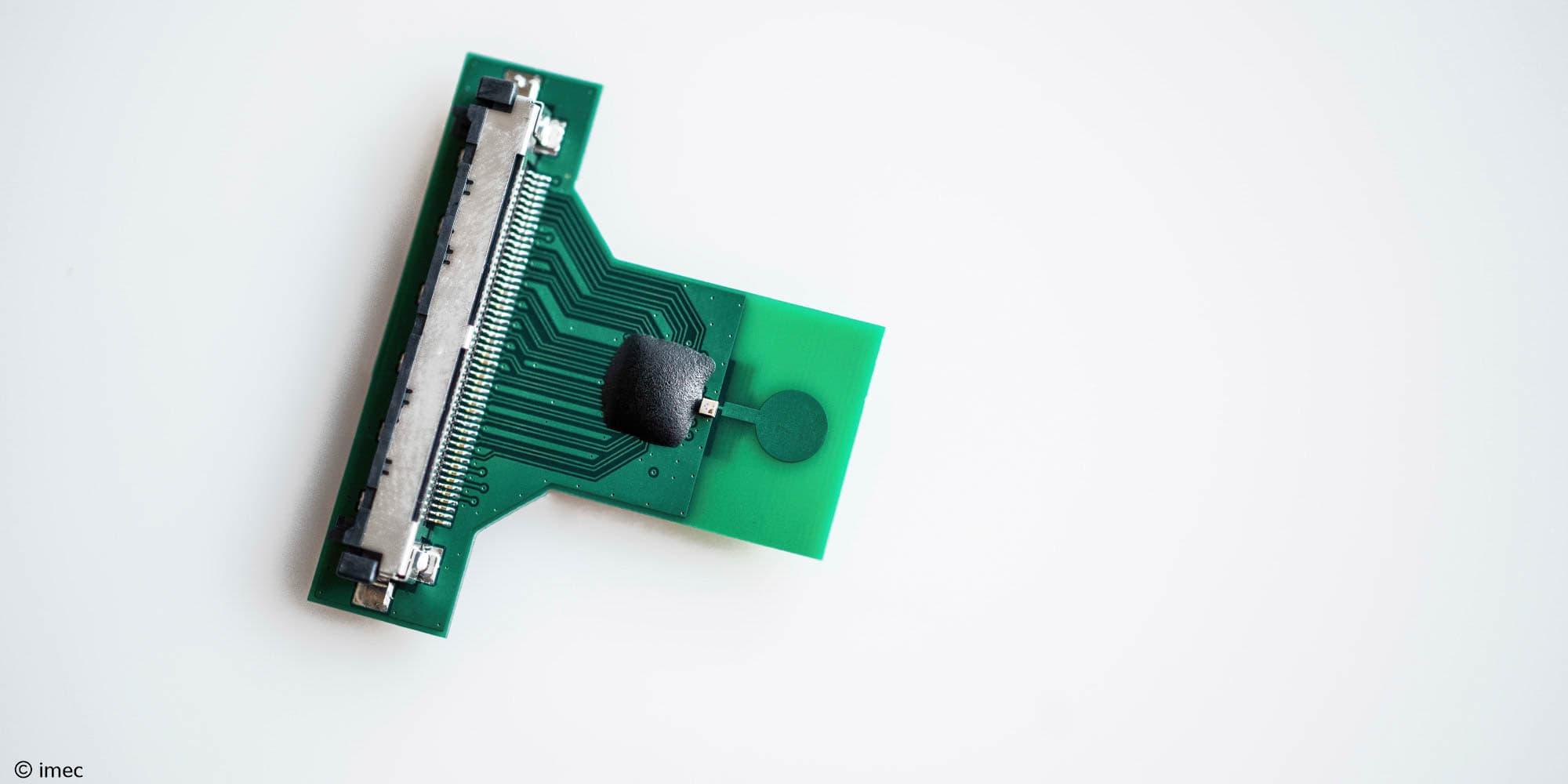

The cooperation between the Met@link partners was essential to make this demo possible and to overcome related hurdles. A first issue that needed to be tackled was the energy-efficiency of plastic chips: they are more power-hungry than regular silicon chips. Moreover, printed antennas typically have a higher resistance and suffer from high energy loss. Thus, the imec researchers first had to enhance the energy-efficiency of their plastic chip. The energy-efficiency advances of such plastic chips have been presented at ISSCC 2017, the flagship conference on circuit design, where a power consumption of only 7.5mW was exhibited for a complete plastic NFC bar code chip in contrast to an extrapolated power consumption of 250mW of previous work. Agfa, in turn, developed a new kind of ink consisting of silver nanoparticles. Because this advanced nanoparticle-based silver ink is a better conductor, it became easier for Quad Industries to print antennas that can function with imec’s plastic chip. All components then returned to Holst Centre where the antennas and chips were assembled to create complete RFID tags. The result is a flexible chip combined with a credit-card size antenna printed on plastic foil that is so thin that it can disappear into almost any product.

Flexible RFID chip with printed antenna

The next step is to use this combination of plastic RFID tag and a reader device with screen-printed antennas to develop new, more advanced applications. On top, the new approach also makes existing production processes more cost-efficient. Wim Christiaens “For Quad Industries this is an important step forward to simplify our production process. Using screen-printed antennas allows us to immediately print both our customized touchscreens and the antennas on the same plastic substrate. This way we can just print everything in one go.”

The read-out system with screen-printed antenna also features a customized printed touchscreen (developed by Quad Industries) with numerical keypad so visitors can gain access to the building by entering a code.

Imagining a smarter, interconnected world

Cheaper technology means more widespread technology. Smart supermarkets, for instance, might become reality soon. Plastic RFID tags with screen-printed antennas could bridge the gap between online and offline shopping. Online shops are able to track consumers’ thinking process: they can see what you’ve bought in the past, what you’ve clicked on and how many times, what you’ve moved to your virtual shopping cart and then removed again. This is valuable information that physical shops miss out on. A company like Quad Industries could, for instance, develop a smart shelf with an integrated RFID reader. If you then use cheap and flexible plastic RFID tags with screen-printed antennas in products’ packaging, you can track how many times each product is picked up and put back. It also makes it easier to monitor a shop’s stock or to check whether there are any items past the expiry date. Because plastic electronics can be mass produced via large-area manufacturing, this would hardly affect the products’ price. Thus, plastic RFID tags could become retailers’ new bar codes.

At the moment, imec’s plastic chips only contain a unique identifier that can be read by a custom read-out system or a smartphone. The next step is to integrate sensors, batteries, programmable memories and displays into these plastic tags. Once these extra functionalities have been added, we can really start to imagine a world where even every-day objects have become smart. For instance, one possible application is the creation of smart blisters - with small plastic RFID tags being integrated into pharmaceutical packaging. The chips could then track whether or not you’ve taken your daily medication and could send reminders to your smartphone if necessary. This kind of tag could also be used to track individual products throughout the entire transportation process: using sensors to monitor temperature and freshness. “The possibilities are almost endless. Because plastic electronics are so much cheaper and can be invisibly integrated into virtually any product, we can really let our imagination run wild,” says Kris Myny.

To pave the way for this Internet of Things, strategic partnerships between research and industry partners are essential. Kris Myny: “Quad Industries can integrate our technology in new, practical applications. They have the experience and customer base to do this.” Wim Christaens adds: “As a technology provider, we need to stay one step ahead of the market to provide innovative solutions to our customers. That’s why the cooperation with imec is so important to us. We’re both in Flanders, so working together is easy and we’re a good fit. The advantage of a project like Met@link is also that we’ve become acquainted with each other’s needs and possibilities. So we’re definitely interested in looking into future collaboration opportunities with imec.”

Want to know more?

- Kris Myny won the poster award at the SIM User Forum 2017. Click here to see the poster, which gives more information on the demo developed within the Met@link project.

- Video that illustrates the future application possibilities of plastic RFID chips

- Video on Kris Myny’s ERC Starting Grant project FLICs (716426); one of the key achievements of this project was making plastic chips more energy-efficient, enabling the combination with screen-printed antennas.`

[1] SIM is an independent innovation-initiative that aims to strengthen the competitive position of the Flemish material industry by stimulating scientific research and by encouraging collaboration between the industry and research institutions. The original aim of the SIM-SOPPOM program was to develop printed solar cells, but the scope was then broadened to include printed photonics, printed energy and printed electronics. Met@link is the first project that was defined within this expanded SOPPOM+ program.

Kris Myny received his MSc in Electrical Engineering from the Katholieke Hogeschool Limburg in 2002. In 2004 he joined imec’s research team and started working on the development of robust plastic circuitry. In 2013 he obtained a PhD at KU Leuven. He is now a Principal Member of Technical Staff at imec and specializes in circuit design for flexible thin-film transistor circuits. His work has been published and presented in numerous international journals and conferences and has received considerable press attention. He was listed as one of Belgium’s top tech pioneers by the business newspaper De Tijd. Last year he also received a prestigious ERC Starting Grant from the European Commission to enable his breakthrough research in thin-film transistor circuits.

Wim Christiaens graduated as a MSc in Electrical Engineering at Ghent University in 2004. He then obtained a PhD in Electronics Engineering from Ghent University in 2009 for his work on the integration of passive and active components inside flexible circuit boards. In 2014 he joined Quad Industries as R&D director to coordinate all innovations with a strong focus on exploring new technologies and applications in the field of (screen-)printed electronics.

Published on:

5 July 2017