Imo-imomec, an imec research group at Hasselt University, is located on the UHasselt Campus, just a stone's throw away from Brussels and imec’s headquarters in Leuven (Belgium). Behind the somewhat futuristic façade, amidst an abundance of green, over 160 researchers and engineers generate leading knowledge in materials research. With a focus on sustainability and health, they perform R&D up to the demonstrator level and provide materials characterization services to industry and academia. Business developers Lieve De Doncker and Jorne Carolus explain how their interdisciplinary teams and dedicated infrastructure translate their fundamental materials R&D into impactful applications.

Co-development of materials and systems at the core of sustainability and health applications

Jorne Carolus: “At imo-imomec, we pro-actively target two application domains, namely: sustainability and healthcare, though our technologies and expertise can be equally valuable for other sectors. In the sustainability domain, we mainly cover technologies for solar energy generation, energy conversion and energy storage, and sustainable and smart materials. In the domain of healthcare, our portfolio mainly targets highly sensitive and selective (bio)sensing applications.”

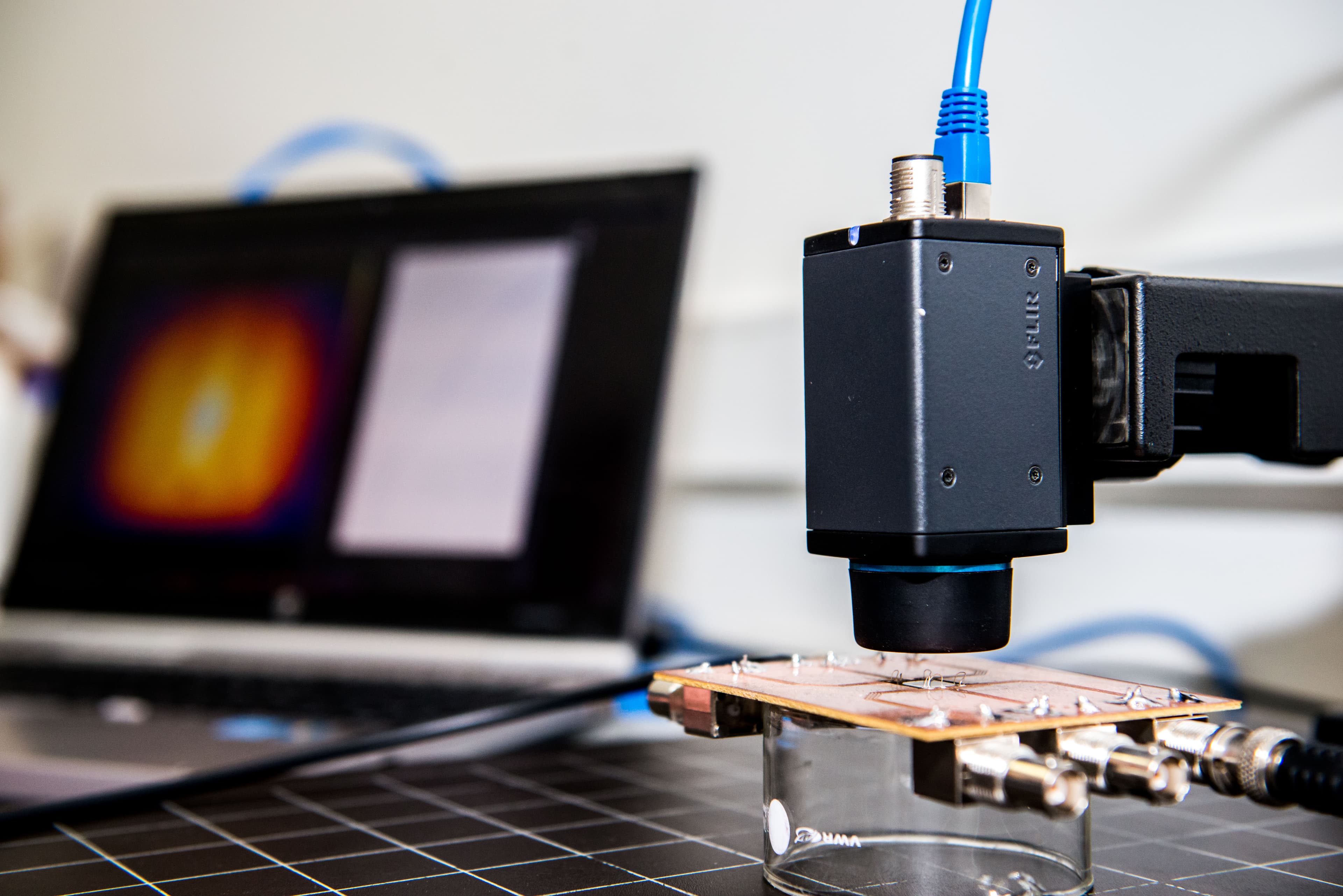

Lieve De Doncker: “In both focus areas, we need a variety of skillsets. For example, a biosensor contains biological and chemical compounds that trigger physical phenomena such as changes in temperature or thermal conductivity, which need to be captured by electronic readout circuitry and translated into useful information for the end-user. That’s why we have chemists and physicists working closely together with engineers and system developers. To design effective prototypes and working systems, in an iterative way, they go back and forth between their fields of expertise and from lab to demonstrator.”

From behind a somewhat futuristic façade, imo-imomec teams proactively focus on R&D for health and sustainability applications and add value to other sectors as well. © Liesbeth Driessen

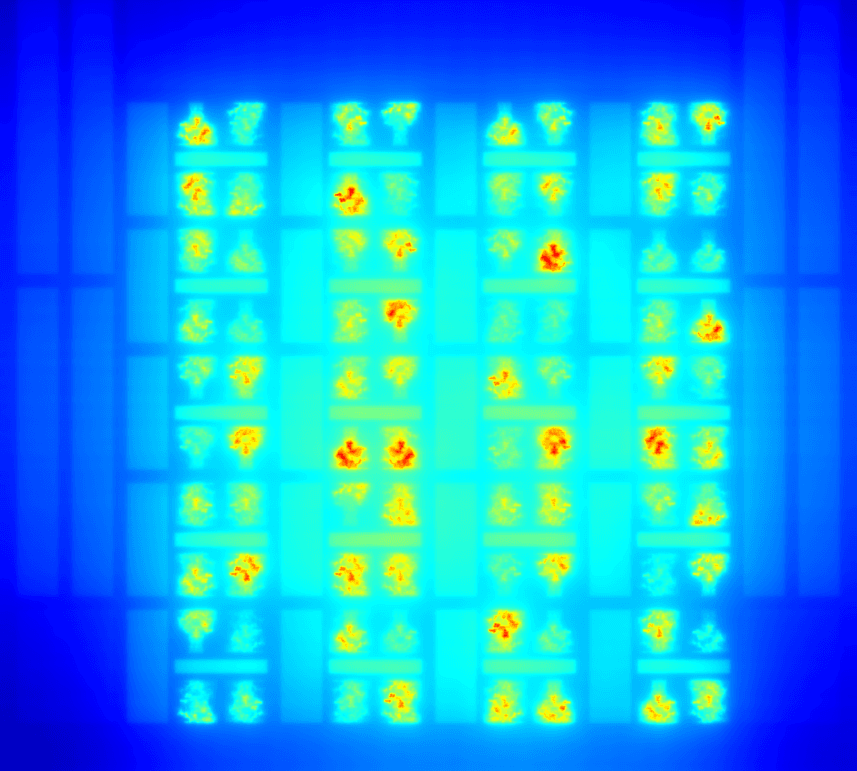

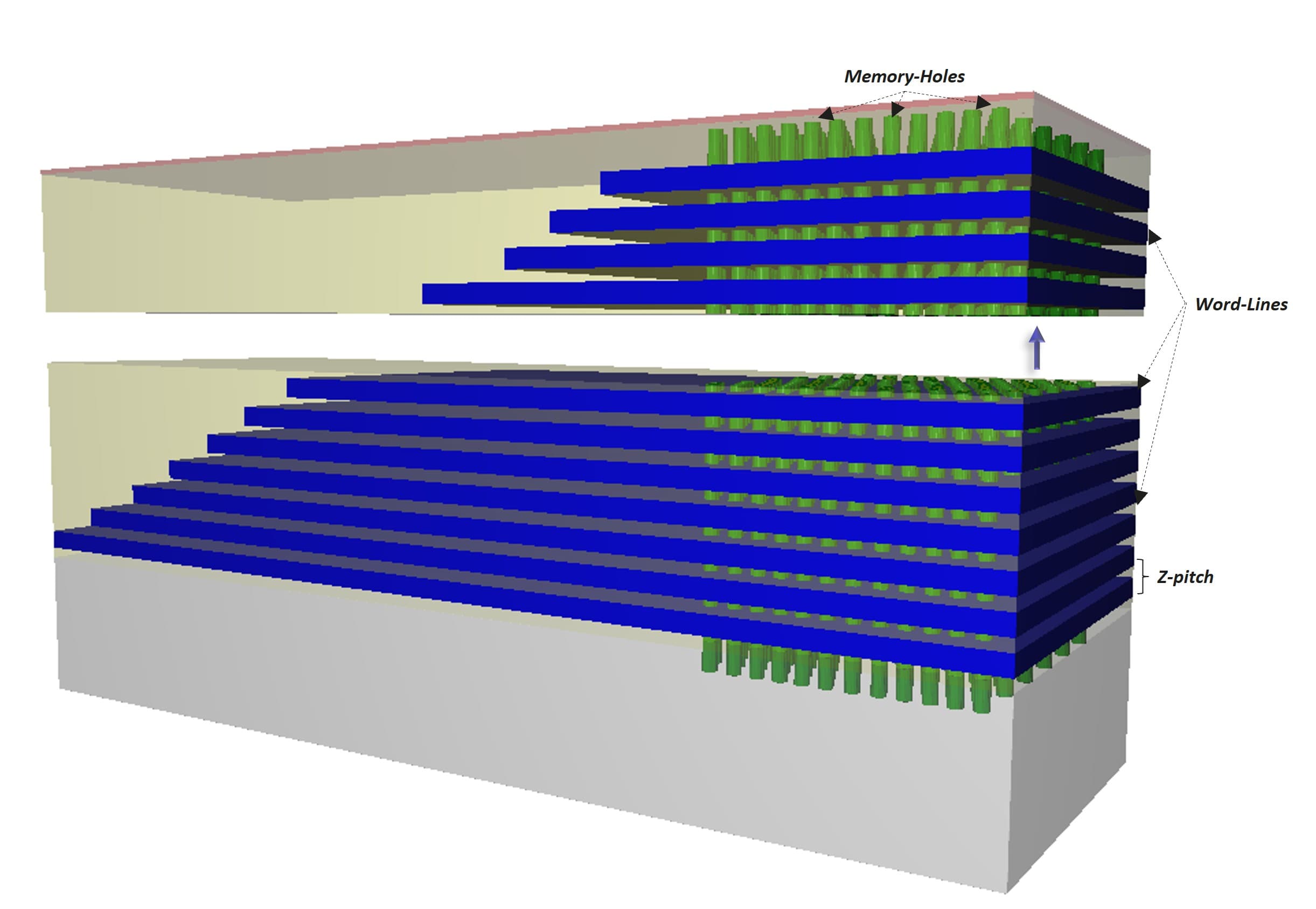

Among the recent tangible outcomes of imo-imomec R&D teams are diamond-based magnetometers developed for several applications. For example, the one in the OSCAR-QUBE, a device that will be used on the International Space Station (ISS) to measure magnetic fields (see further reading at the end of this article). These sensors take advantage of quantum effects at ambient conditions. Namely, electron spins of nitrogen-vacancy color centers (engineered impurities in the diamond crystallographic lattice), which become polarized by shining a laser light on the diamond. The resulting light intensity coming out of the diamond serves as a ‘fingerprint’ of the measured magnetic field orientation and intensity. Jorne Carolus: “The quantum-technologies at the basis of these sensors could potentially be applied in the biological or pharmaceutic domains as well. For example, to increase the resolution and sensitivity of magnetic-resonance techniques to monitor chemical reactions.”

Related but not identical are potential applications based on nuclear spins that can be engineered in synthetic diamond. These could prove their value in future quantum applications such as quantum computation, communication, and sensing. The main parameter for the attractiveness of nuclear spins is their long coherence time, which is in the range of seconds at ambient temperatures and can go up to tens of minutes at cryogenic temperatures around 10K. The most recent results on electrically reading the nuclear spin state were published in Nature Communications recently (see further reading at the end of this article).

Another research domain at imo-imomec that generates much traction is ultra-precise (biochemical) sensing. Lieve De Doncker: “We have, for example, substantial expertise in sensors that employ molecularly imprinted polymers (MIPs) to detect target molecules in different complex media. MIPs are synthetic receptors that can be used as an alternative to natural receptors such as antibodies, enzymes, cells, etc. They are cross-linked polymer matrices shaped in the presence of the molecule of interest (target molecule). Subsequent removal of the target molecule after polymerization yields nanocavities inside the MIP, which are complementary in size, shape and arrangement of functional groups to the target molecule. These cavities have the potential to rebind the target molecule with high specificity. You can compare it with the unique matching of a lock and its key.”

Because a MIP is engineered to adhere to one specific analyte, it can act as a selective and highly sensitive sensor relevant to food, health, and environmental safety. Think, for example, of in-line or at-line monitoring of contaminants in the supply line and waste streams, quality control of raw materials and products in the food industry, etc. The imprinting can also be extended to large structures such as cells and bacteria, using surface imprinted polymers (SIPs) in which thin films with surface imprints are created to detect the target structures.

Jorne Carolus: “Over the years, we have not only focused on MIP-technology but also successfully demonstrated other types of sensors. Think of smart band-aids that speed up wound healing. Or a smart patch with integrated sensors that monitor the vital signs of hospitalized COVID patients, which we realized together with other partners in an international consortium.”

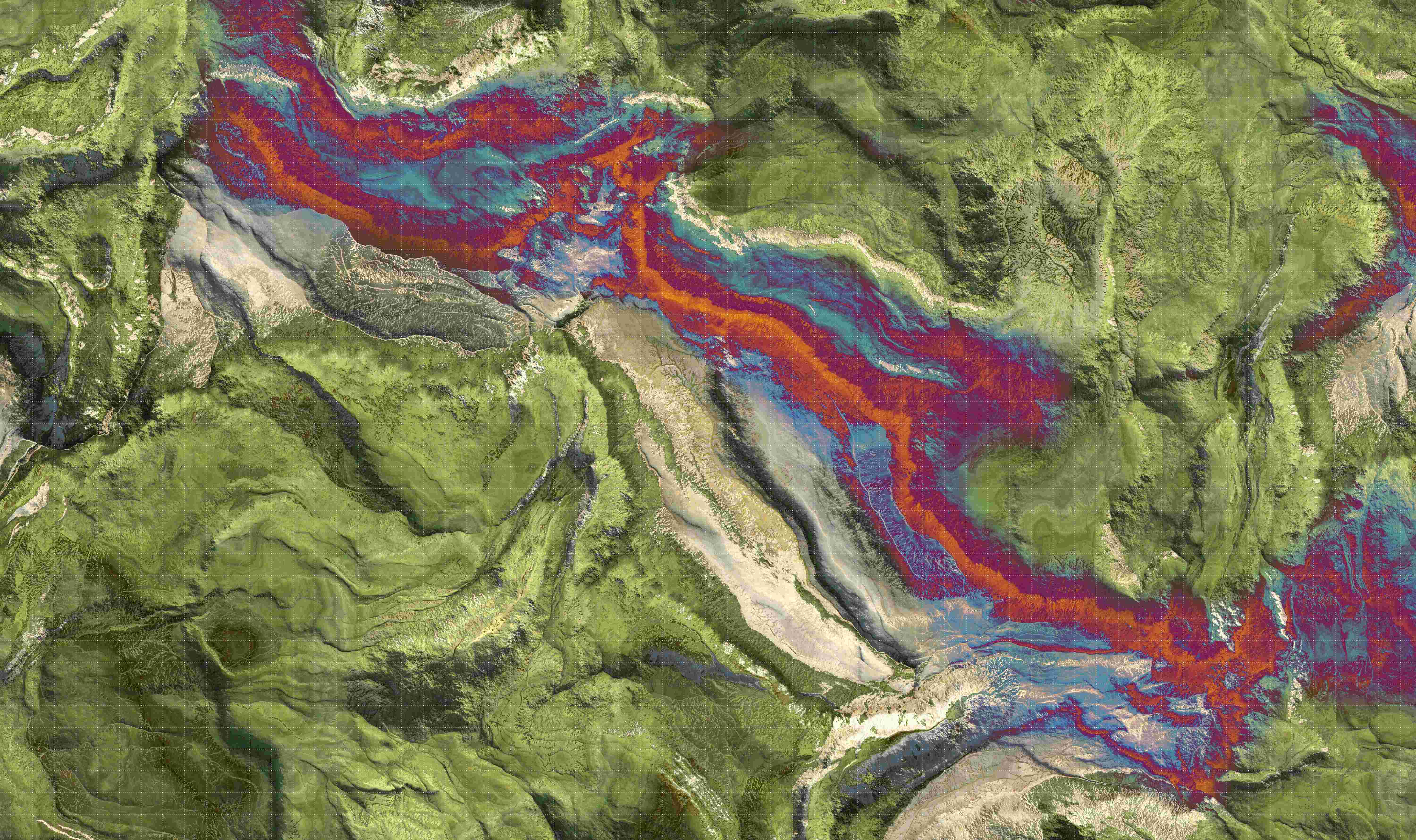

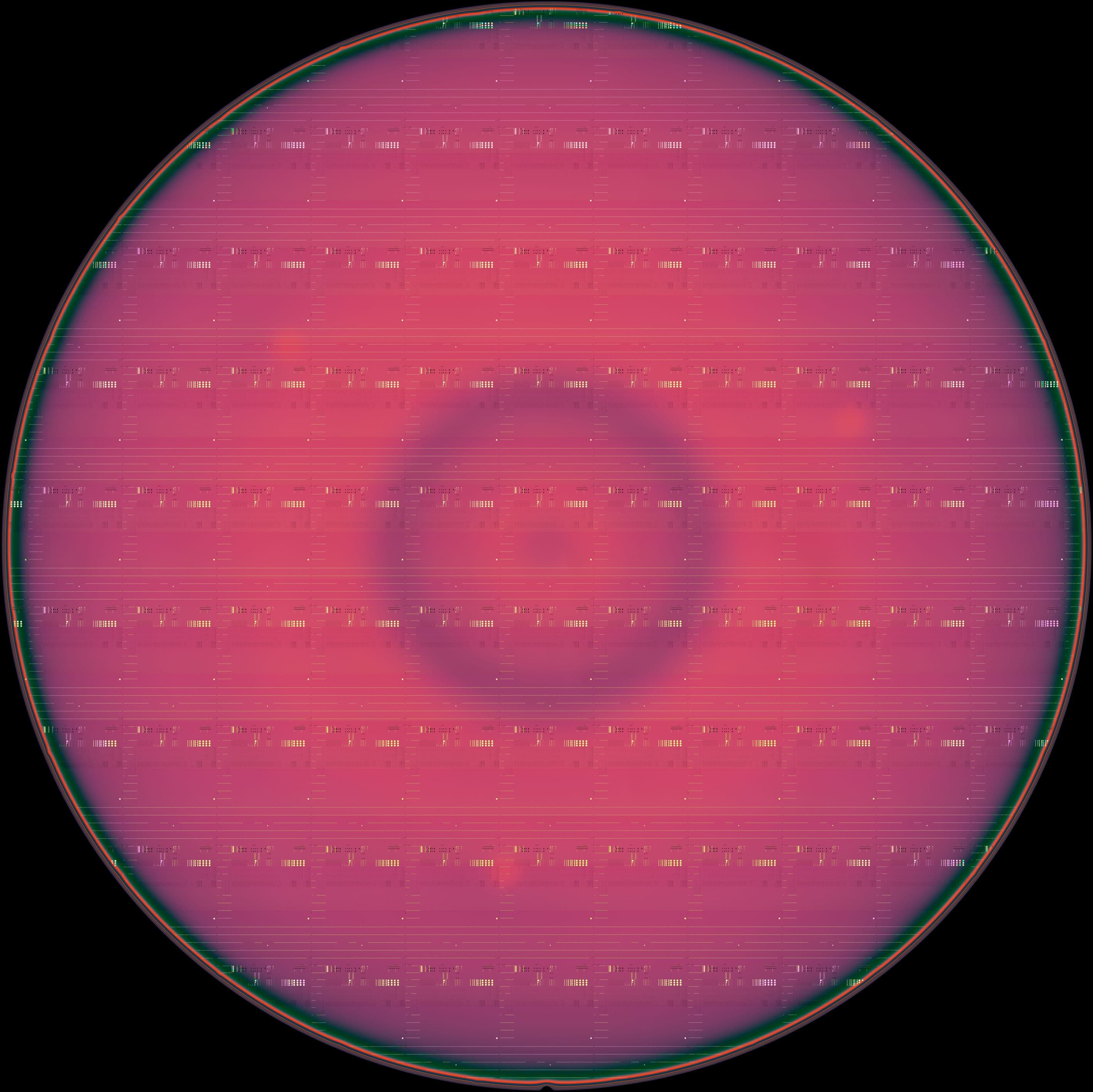

In the strategic focus domain of energy, imo-imomec generates substantial traction in developing next-generation photovoltaics (PV) and its adjacent application areas (see further reading at the end of this article). Here, the department focuses on energy generation, conversion, and storage. Lieve De Doncker: “An example of energy conversion are the activities on C02 conversion into methane or synthetic fuels, assisted by PV and hydrogen technologies. It could generate a dual gain by reducing C02 and our dependency on fossil fuels simultaneously. Here, we work closely together with the imec program called power-to-molecules. On the topic of energy storage, the most noteworthy activity is probably our research into alternatives for the widespread Lithium-ion batteries. With the aim to develop solutions that carry less weight but show similar energy-storage capacities. This could be important for range extension in electric vehicles but also for aerial applications such as drones. These strategic important research lines are being created in collaboration with a wide range of players in the field in Flanders, and here we are also increasingly getting more successful on the European level.”

Last but not least, there’s also the department’s smart and sustainable materials expertise in areas such as plastic recycling and stretchable electronics. For example, in plastic recycling, the imo-imomec experts momentarily focus on textile waste from the fashion industry to upcycle the recovered fabrics into more durable and long-lasting materials.

In stretchable electronics, the department is currently pursuing a spin-off trajectory to valorize its expertise towards industrial applications in the agro-food industry (e.g., softer grabbing arms in fruit-handling robots). But also healthcare applications are widely interesting for flexible electronics (e.g., for prostheses, to diagnose erectile disorders and underlying health conditions, wound healing, etc.).

Industry compatibility as a default target

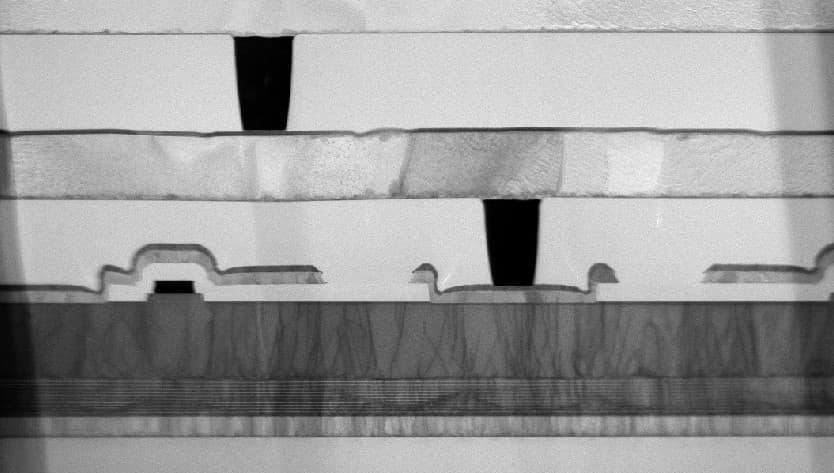

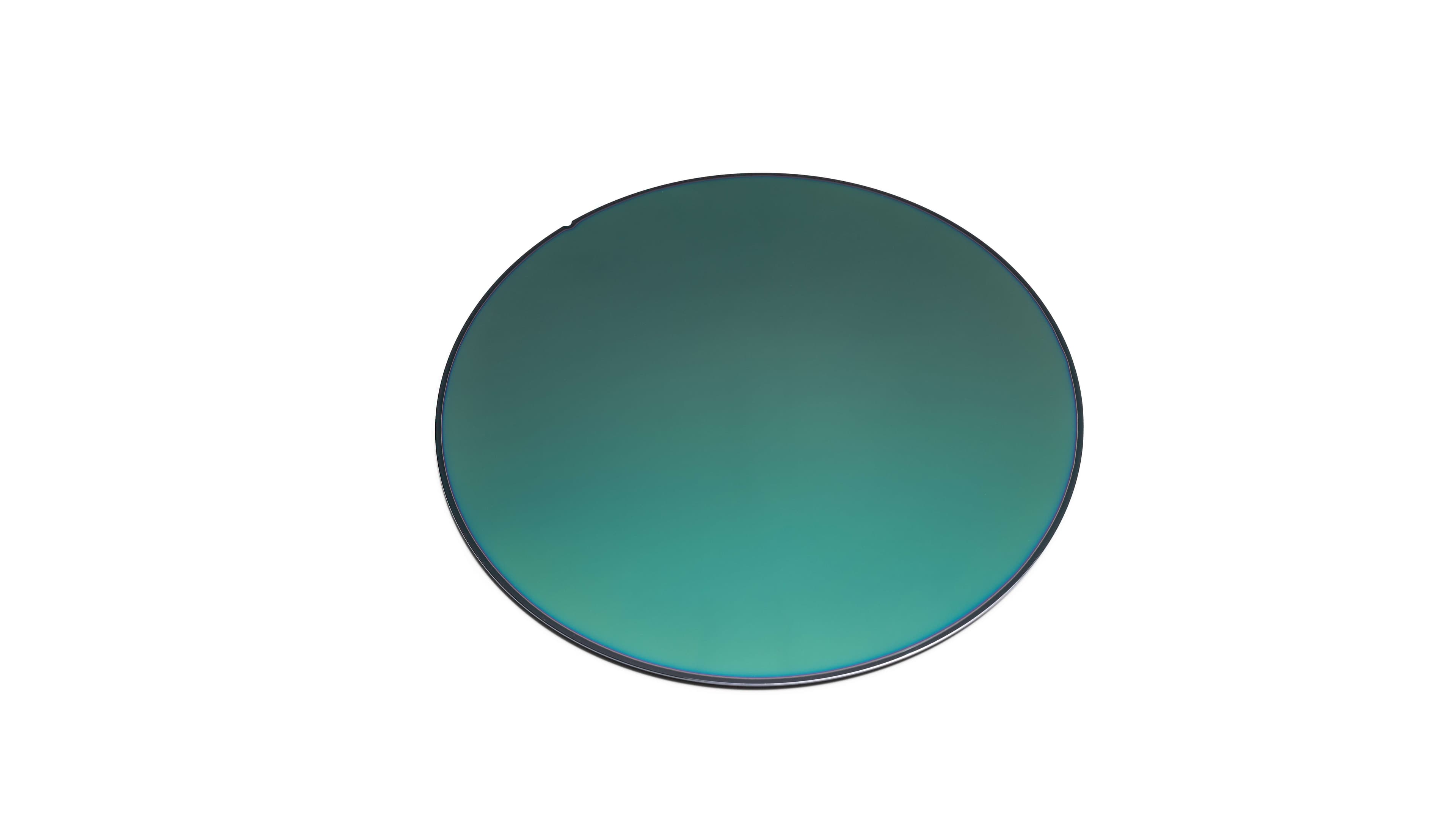

Materials development and processing are common foundations underneath all the activities and realizations above; and a historical strength of imo-imomec. With this, the investigation and improvement of intrinsic material properties are one part of the story and R&D focus. But even more important is the ability of imo-imomec to process and deposit these advanced and dedicated materials in an industry-compatible way.

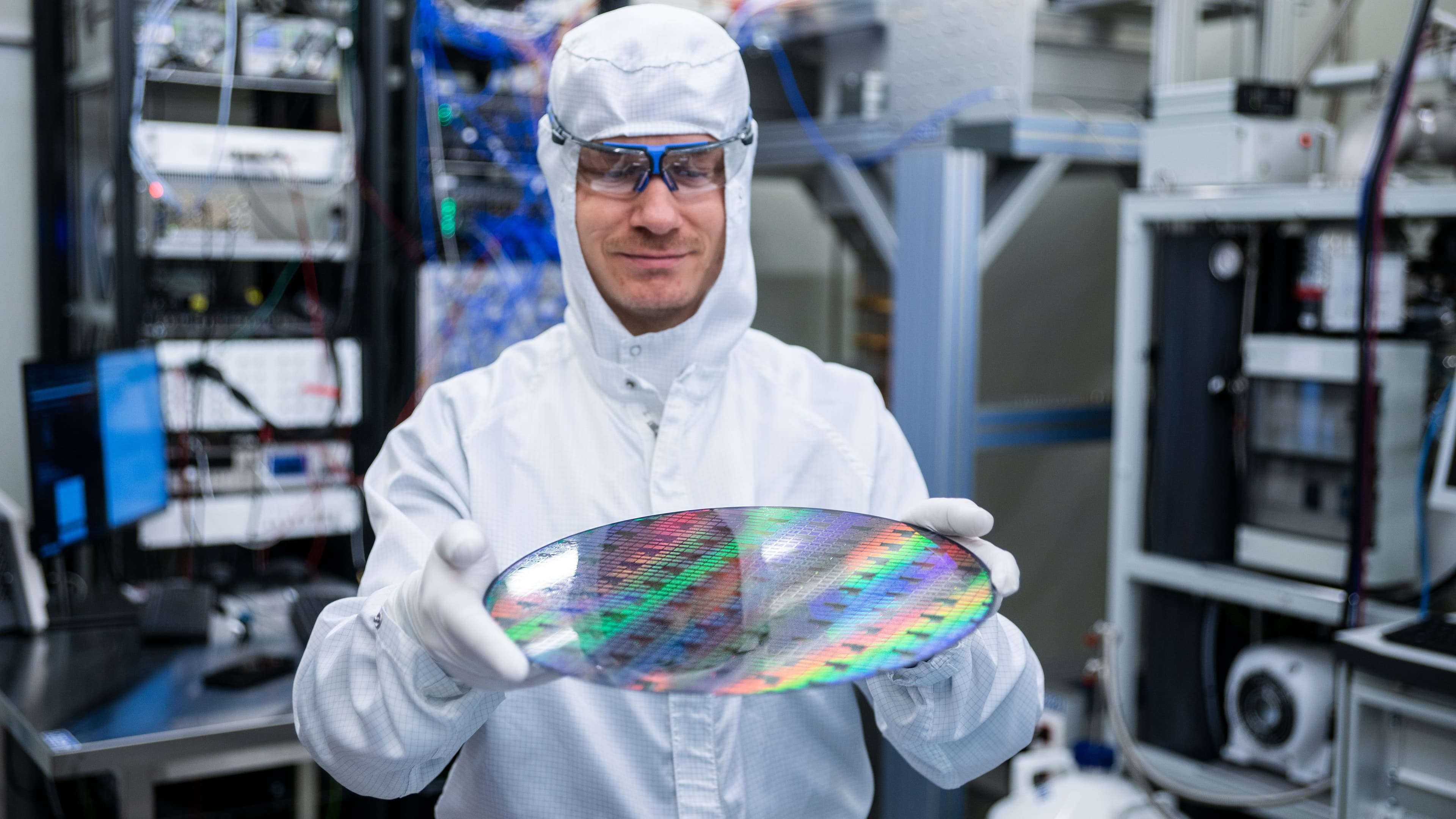

At imo-imomec, infrastructure is available to cover the entire spectrum from fundamental materials research all the way up to failure analyses or reliability testing of materials and devices. © Liesbeth Driessen

Jorne Carolus: “Think about ways to create seed layers with diamond nanoparticles on which homogeneous large-area synthetic diamond layers can grow. This seeding is usually performed on a lab scale by spin-coating on smaller surfaces for proof of concepts. For compatibility with roll-to-roll or other mass-manufacturing techniques, we transfer these processes to higher-throughput equivalents, such as ultrasonic spray coating.

In other examples, such as for specific coating applications in organic electronics, the obstacle to move towards industrial compatibility can lie in replacing processes requiring a vacuum or other controlled environment with effective equivalents in ambient conditions. In general, one could say that the aim is always to find processes with sufficient quality and throughput at an affordable cost.”

Lieve De Doncker: “Here again, it is important to have the collaboration and knowledge exchange between chemists, physicists, and engineers. Through continuous iterations, they can finetune the materials and formulations, for example, in terms of rheological properties such as viscosity, surface free energy, and substrate interaction.”

Services and R&D partnerships

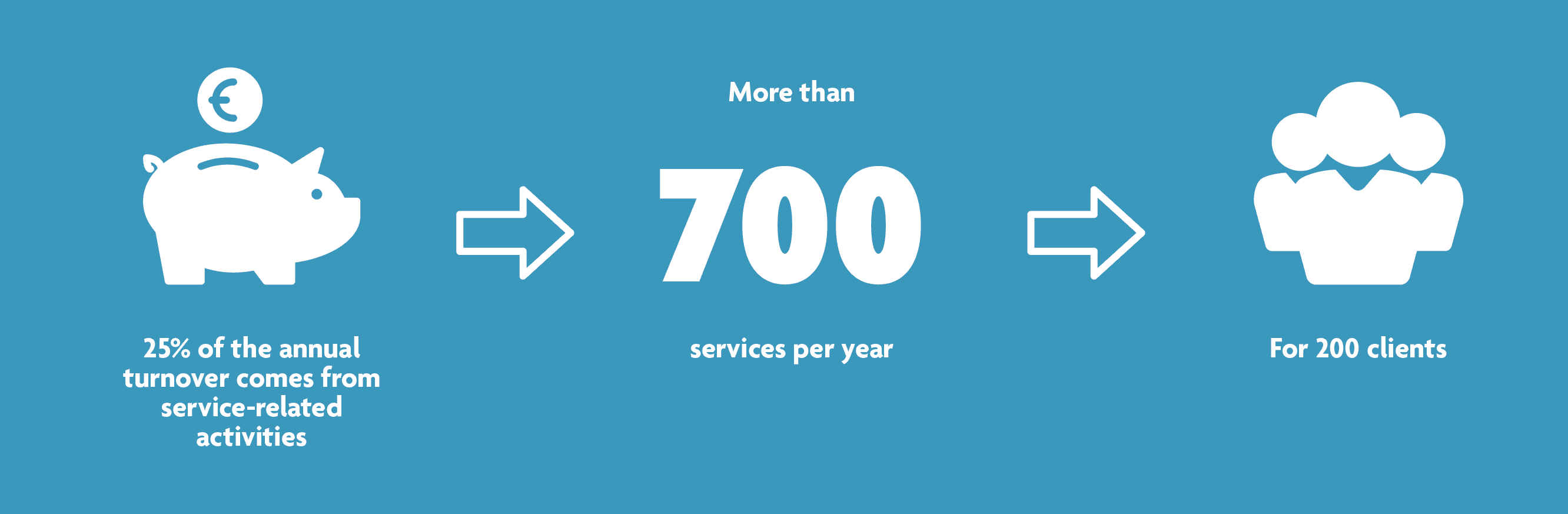

Aside from the availability of varied skillsets, an all-encompassing machine park and R&D infrastructure also belong to the imo-imomec assets. Lieve De Doncker: “Since we have the full spectrum of capabilities such as materials deposition and characterization available for our own R&D, we also put this knowledge and infrastructure to use for external parties. Companies big or small, and other research institutes can call upon our support for the development and characterization of their materials. And this is from basic research all the way up to failure analyses or reliability testing of materials and devices. We want to keep the threshold as low as possible, so don’t shy away from working with small companies or in low-volume agreements.”

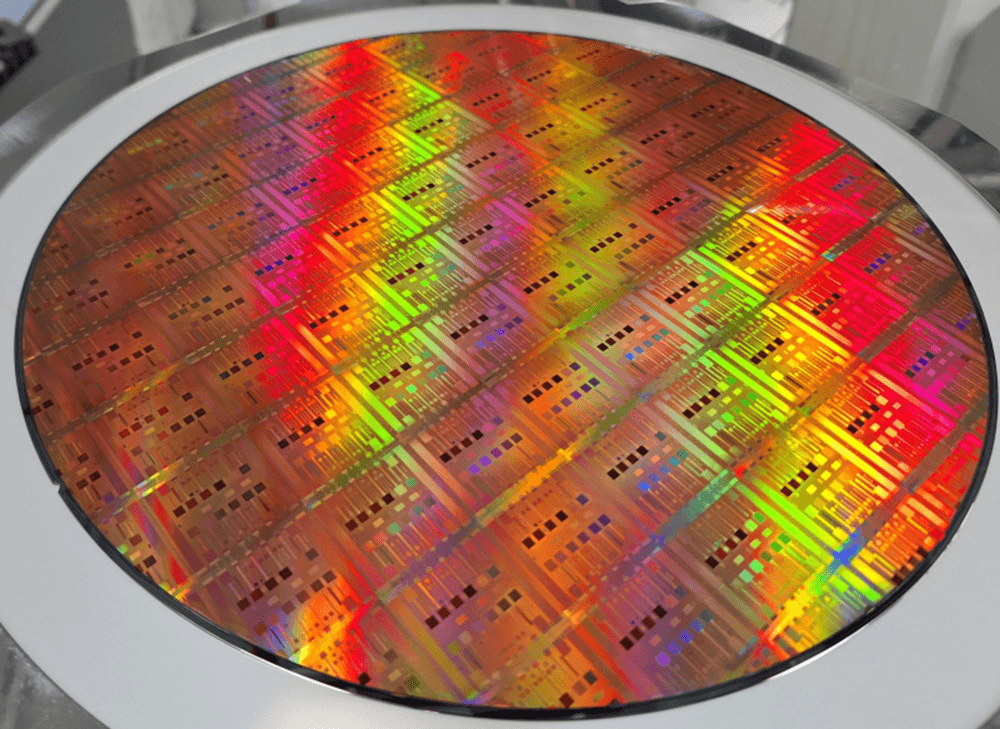

Imo-imomec makes its expertise and infrastructure available for industrial and academic clients and partners. © imec

Jorne Carolus: ”We can scale our efforts towards the specific needs and size of our industrial clients and partners. Depending on the type of company and challenge, we can act as a supplier or work more closely together as a development partner. For larger companies, we can tap into specific collaborations and funding schemes that are offered by our regional or national governments or by the EU. We can also leverage our strategic partnerships, such as the one with imec, which allows us to align research roadmaps and use each other’s expertise and technical infrastructure. For similar reasons, there is our participation in EnergyVille, where next-generation technologies are developed and matured for energy generation, conversion, and storage.

Further in-depth reading:

- In the picture #1: Oscar-Qube: diamond-based magnetic sensing in space

- In the picture #2: Quantum technology R&D at imo-imomec

- In the picture #3: The potential of thin-film materials for energy generation and conversion

Want to know more?

Website imo-imomec: IMO - IMOMEC (uhasselt.be)

Dr. Jorne Carolus received his master’s degree in engineering in 2015 from Hasselt University and KU Leuven in Belgium and his Ph.D. degree in 2019 from Hasselt University for his work on potential-induced degradation of photovoltaic solar cells and modules. He is currently a business developer at the institute for materials research (imo-imomec), an imec research group at Hasselt University. He is also affiliated with imec (Leuven, Belgium) and EnergyVille (Genk, Belgium).

Dr. Lieve De Doncker received her master's in physics from KULeuven in 1984 and her Ph.D. in solid-state physics in 1990, also from KULeuven.

She was an active researcher at the Belgian Nuclear Research Centre SCK/CEN for a year in the safeguards field. After that, she worked for 23 years at IWT (now VLAIO), starting as a scientific advisor for the Impuls New Materials program. Then she moved into a coordinator role in IWT activities/funding in materials chemistry and processing, which allowed her to see relevant innovation throughout Flanders and Europe, thus building a broad network in Flanders' industry and research environment.

In search of new challenges, she brought her expertise, knowledge of funding, and network to UHasselt/imec, in 2016. Today Lieve is a business developer at the institute for materials research (imo-imomec), an imec research group at Hasselt University, and is also affiliated with imec (Leuven, Belgium) and EnergyVille (Genk, Belgium).

Published on:

28 August 2021