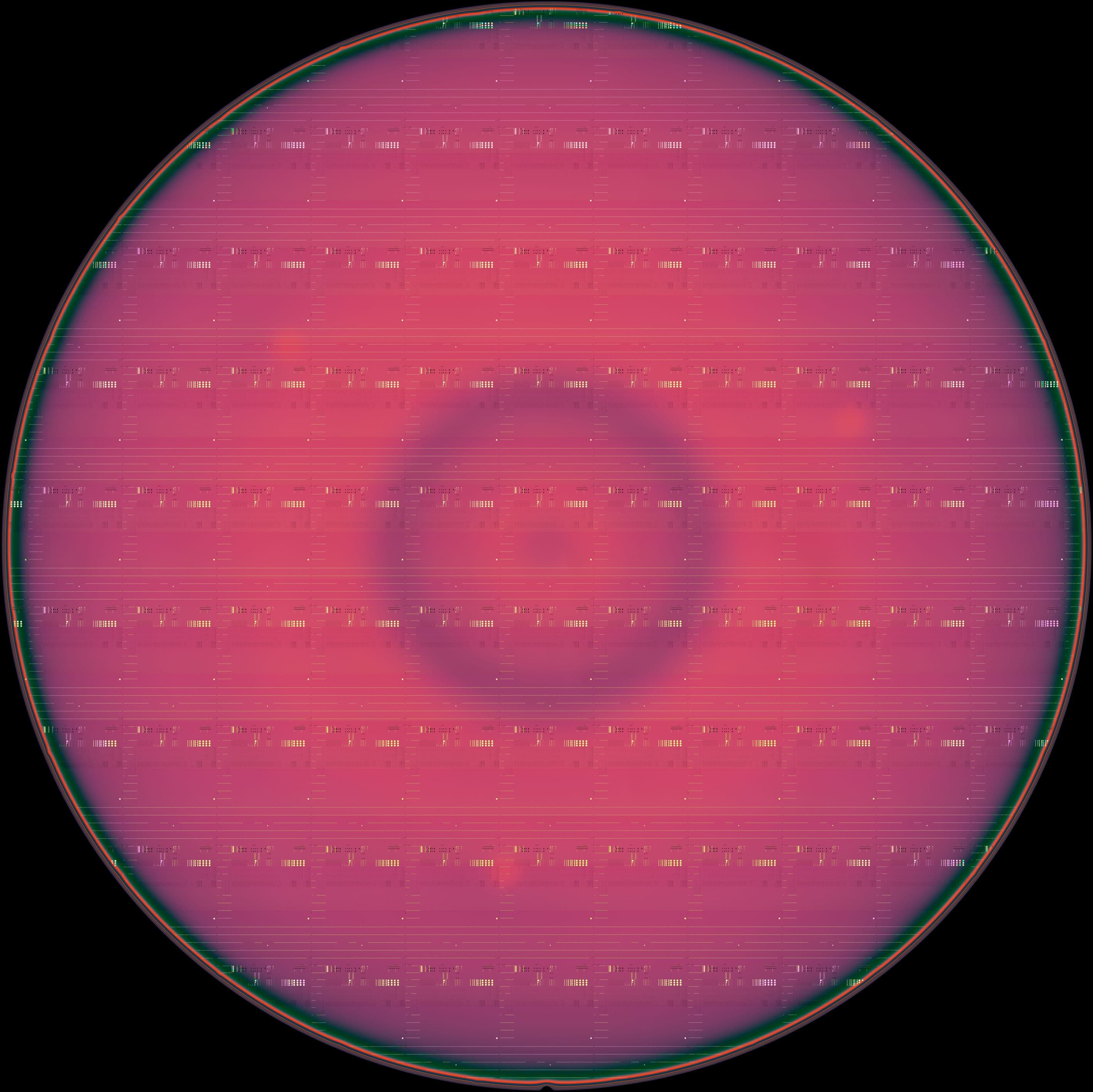

MEMS & microdevices foundry services

Take advantage of imec’s infrastructure and expertise to develop and manufacture your customized MEMS and silicon microdevices.

MEMS is a broad term that refers to micro-electro-mechanical systems that go beyond typical devices, such as gyroscopes. Microdevices, on the other hand, integrate advanced functionalities on tiny surfaces and are produced using advanced micromachining capabilities.

Microdevices are often the invisible innovation engines inside disruptive products. But while their possibilities are huge, their development can be a challenge. Especially the part where you need to devise a reliable manufacturing process.

If that process involves many steps, typical MEMS and CMOS foundries are disinclined to take on your project because they’re too busy with production runs. On the other side, university labs often won’t provide you with the capabilities and expertise to realize a manufacturable process of your device.

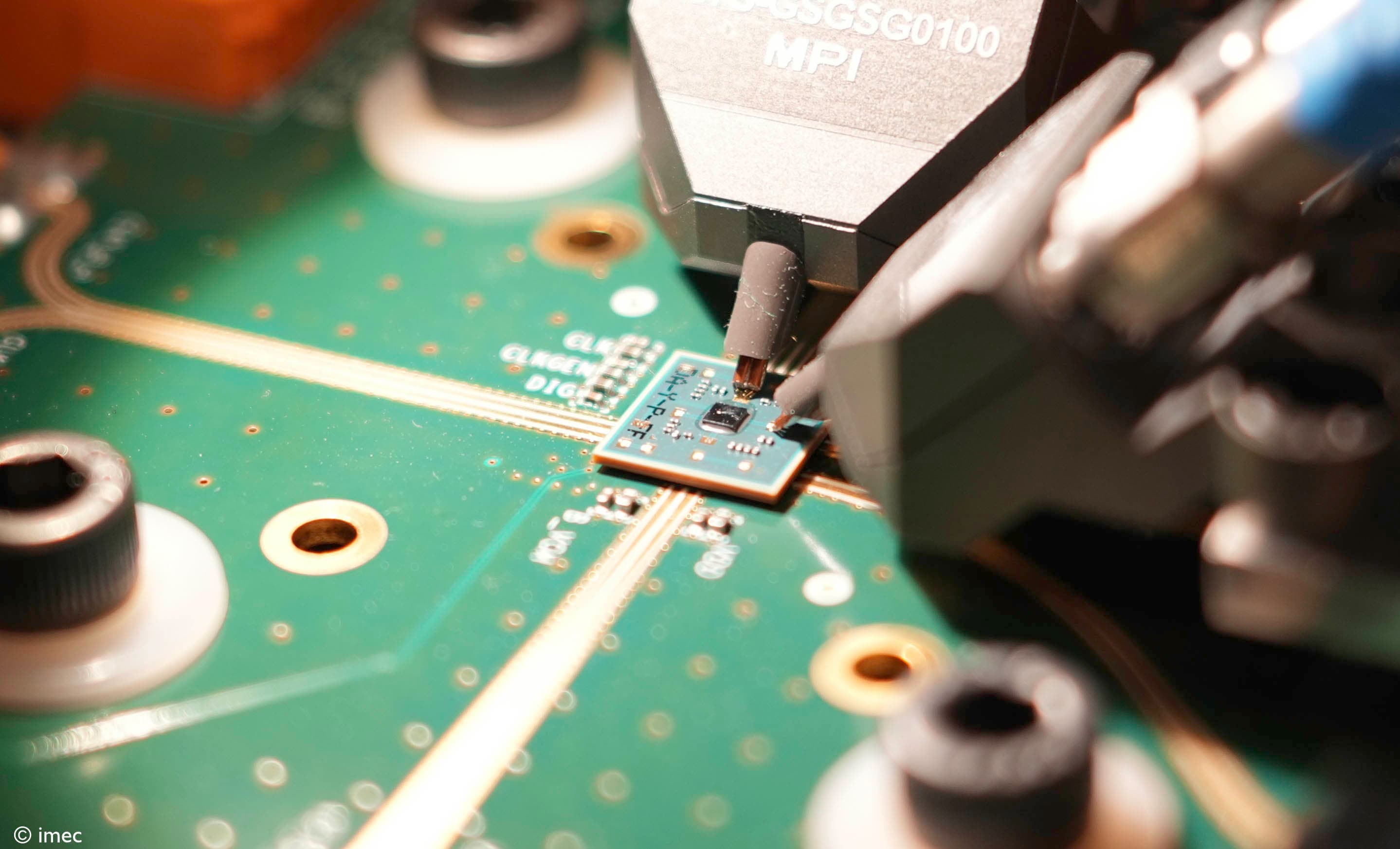

Imec’s objective is to offer its advanced silicon pilot line, technical expertise and IP to allow the development of your advanced MEMS and microdevices. And guide them all the way to prototyping and manufacturing.

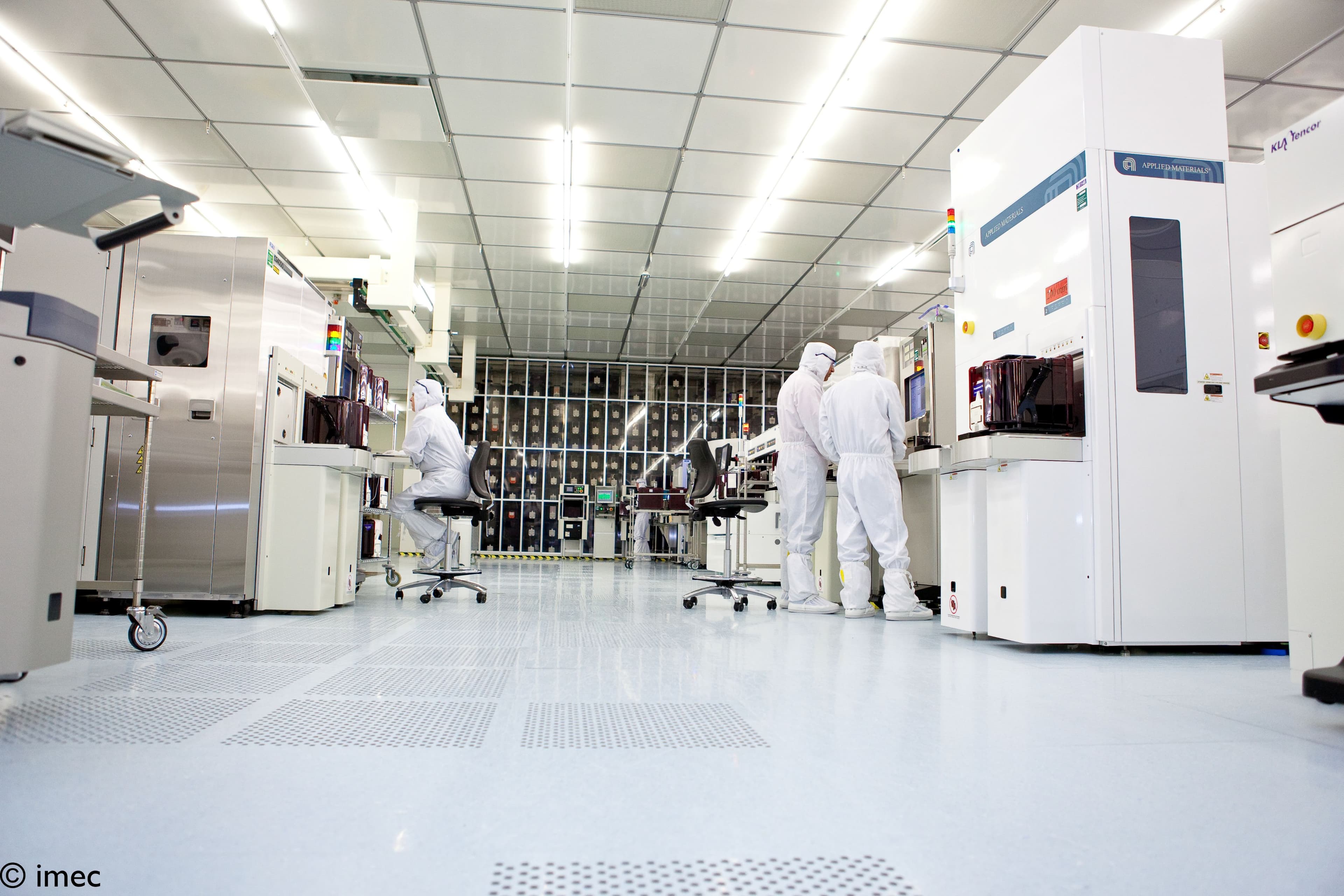

Foundry infrastructure for MEMS and microdevices development

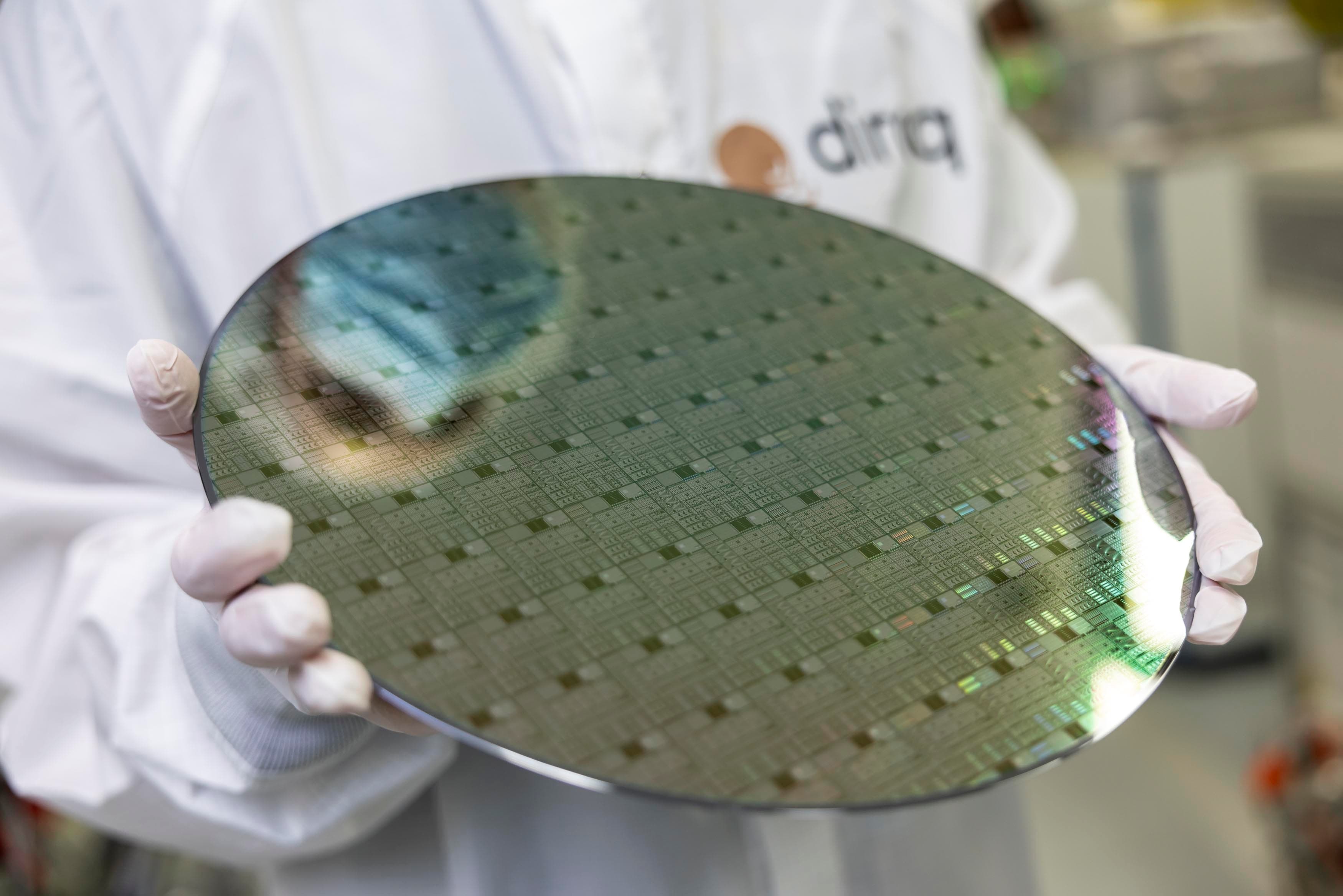

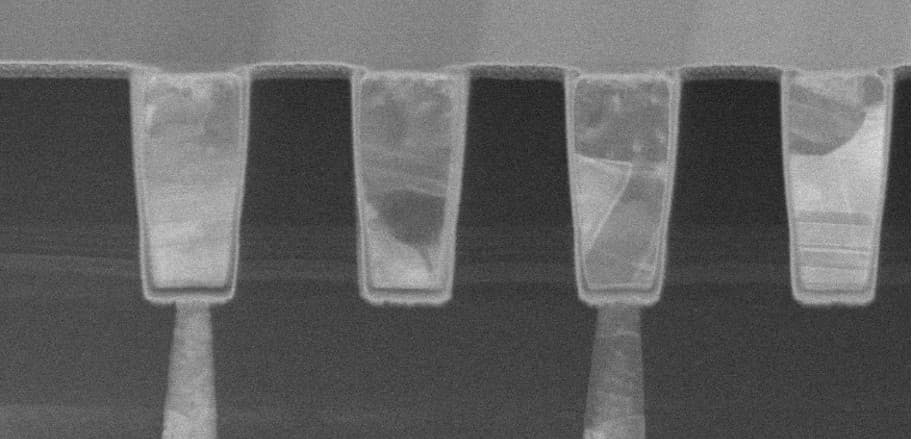

The development of a manufacturable device requires access to the equipment you find in leading CMOS and MEMS foundries. And that’s exactly what you find in imec’s 200-mm cleanroom:

- full set of CMOS-compatible flow capabilities with a wide range of lithography tools

- wide choice of substrates and materials

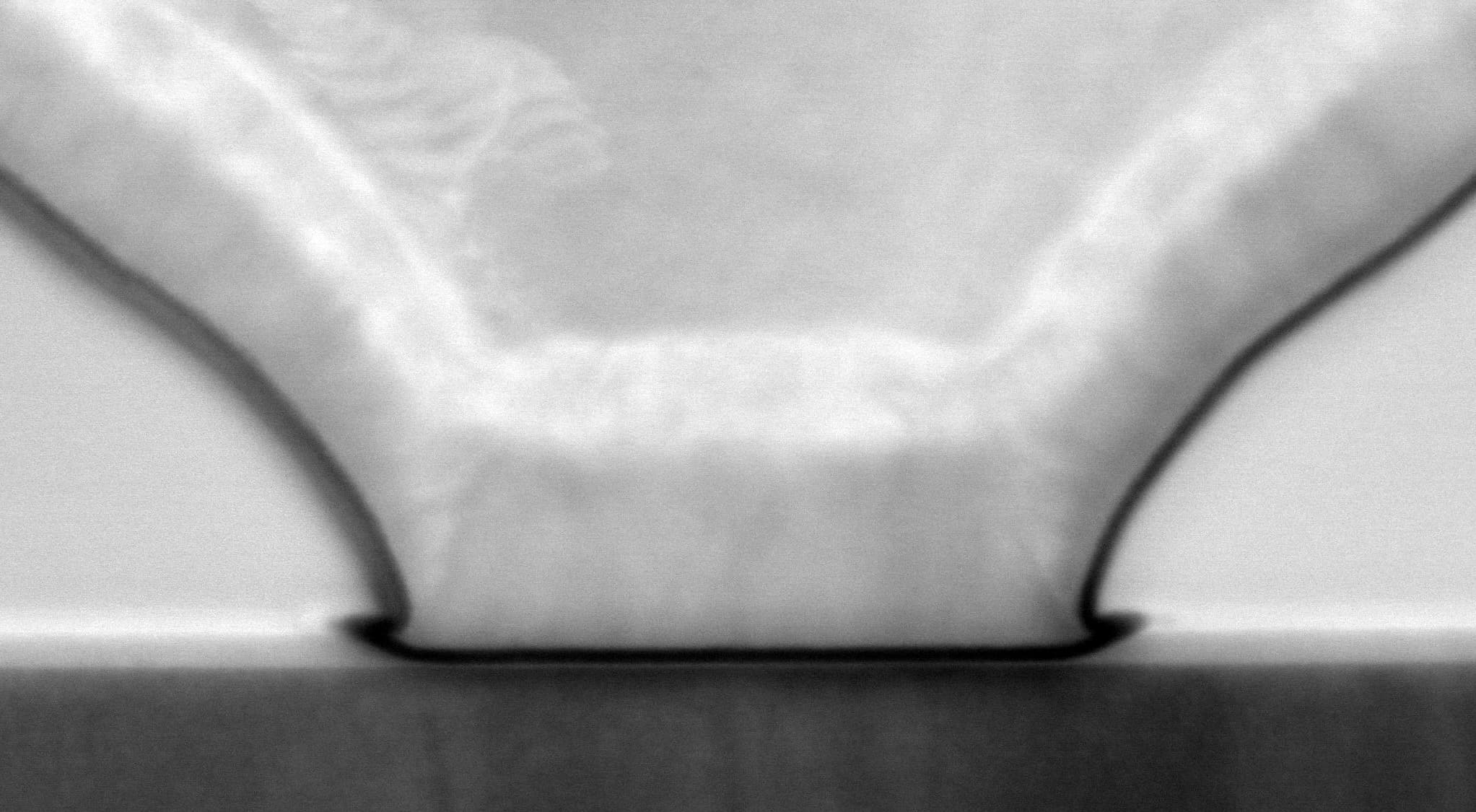

- versatile MEMS & 3D integration platform

- special features such as through-silicon wafer etching and through-silicon via

In addition, the imec facilities host several advanced labs – for instance for material and device characterization and photonics.

For a full overview of our infrastructure, visit this page or download this brochure.

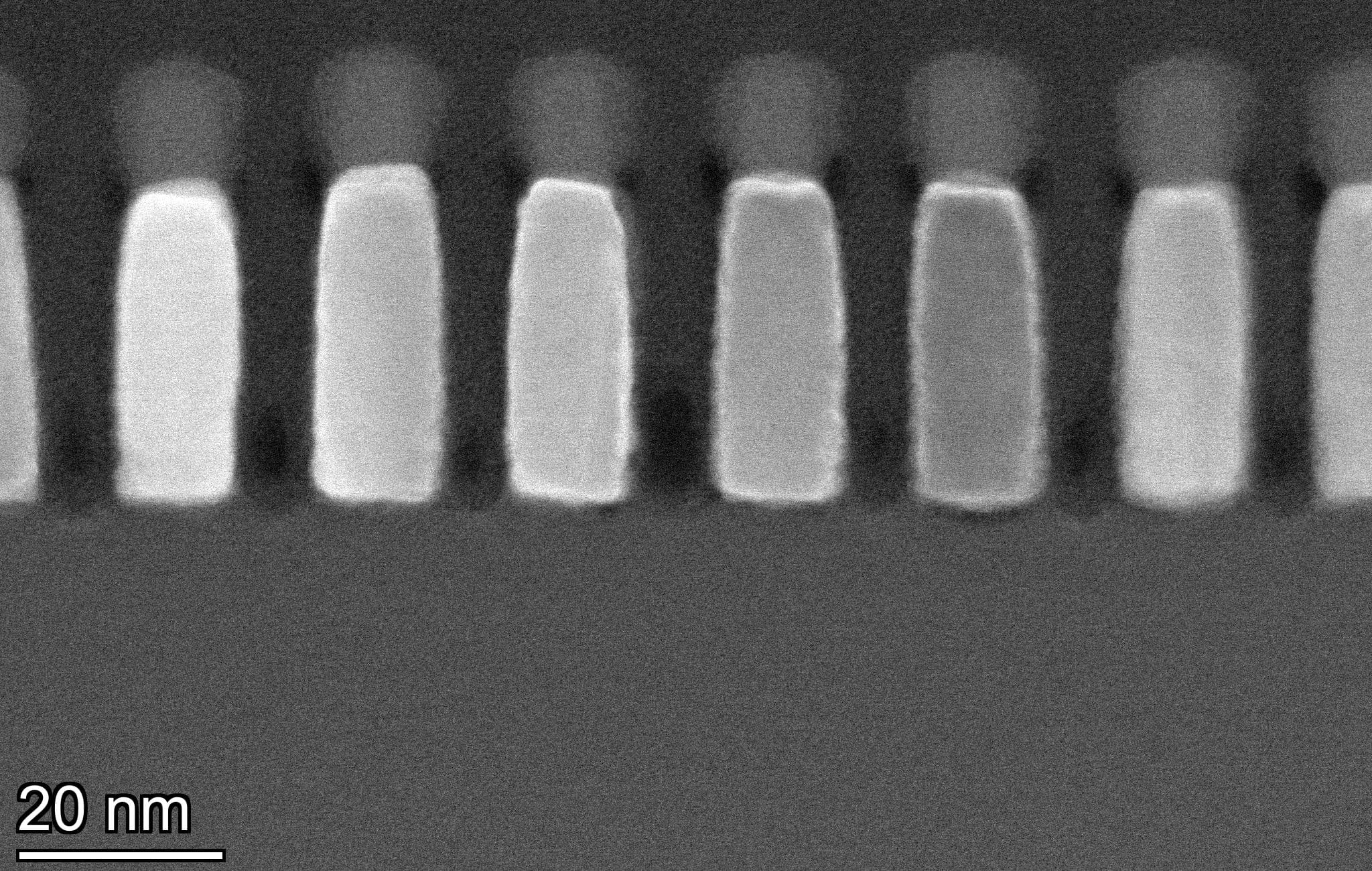

Advanced microdevices technology toolbox

Draw from our vast technology portfolio to enable your chip application or tackle the challenges that come with manufacturing your device:

- customized CMOS imaging

- silicon photonics

- silicon nitride-based photonics

- solid-state optical beamforming

- ultrasound transducers

- flat optics

- silicon microfluidics

- nanoimprint lithography

Development process of your MEMS and microdevices

Do you already have a prototype? Then imec helps you to make it manufacturable. Do you only have a rough idea? Then we guide you through all the steps to a functional product:

- Our experts look at your challenge from different angles to come up with a solution that meets your specifications and that’s manufacturable.

- If needed, we carry out a feasibility study.

- If needed, we design your device and develop the process.

- We realize a first prototype.

- We optimize the design and process technology to assure your device meets the agreed specifications, and then perform a process macro qualification to increase yield and reproducibility.

After that, your device is ready for production:

- Below 1,000 wafers per year, your device can be manufactured in the imec cleanroom

- Above 1,000 wafers per year, the process developed at imec can be easily transferred to a foundry.

Watch a video of how ASML and imec collaborated on EUV image sensors:

Are you ready to talk about your customized MEMS or microdevice challenge with us?