SASS

Smart Automotive Soft Skin

The design and manufacturing of vehicle interiors are set to undergo major changes. One direction is to make the interior surfaces in vehicles smart. For example through technology that remains out of sight, no longer distracting us and forcing us to look at digital tools, but instead offering a background of unobtrusive assistance. The aim of this research project is to help realize such technology by enabling the integration of functional electronics in soft flexible and stretchable substrates.

The challenge: assembling and printing electronics on soft surfaces

Electronic assembly on rigid surfaces is well established and standardized. For soft and stretchable materials, however, there are no established industrial processes yet.

In addition, the technology of printed electronics has been developed for hard thermoplastic materials, which may be flexible but non-stretchable. However the surfaces of medium and high-end cars have much larger surfaces in all types of materials, including some that are flexible.

Adapting the printed electronics to these flexible materials is a challenging R&D topic. Moreover, the assembly should be in accordance with automotive requirements, which are very stringent, especially concerning the reliability of interconnections.

Developing an innovative technology platform

The SASS project will bring together industrial partners and research institutes to develop a new technology platform for automotive interior parts, integrating functional electronics in soft, flexible and stretchable substrates. Such technology will include:

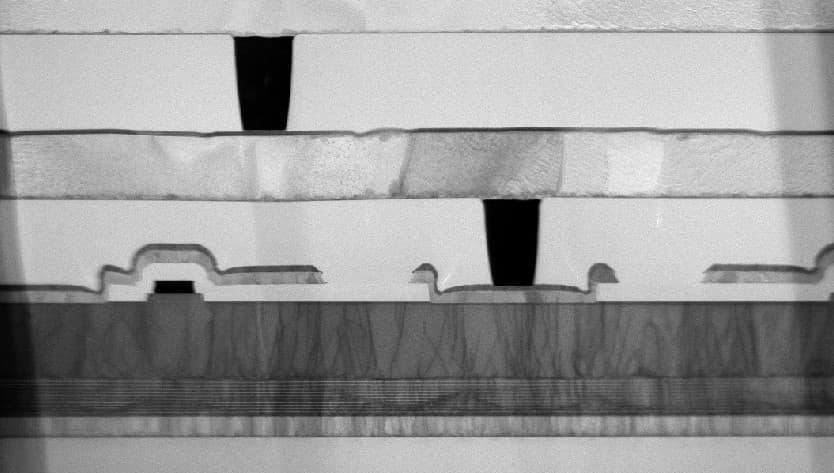

- Electronics completely hidden below the surface.

- Translucent surface materials with intuitive designs.

- Signalization with integrated light sources.

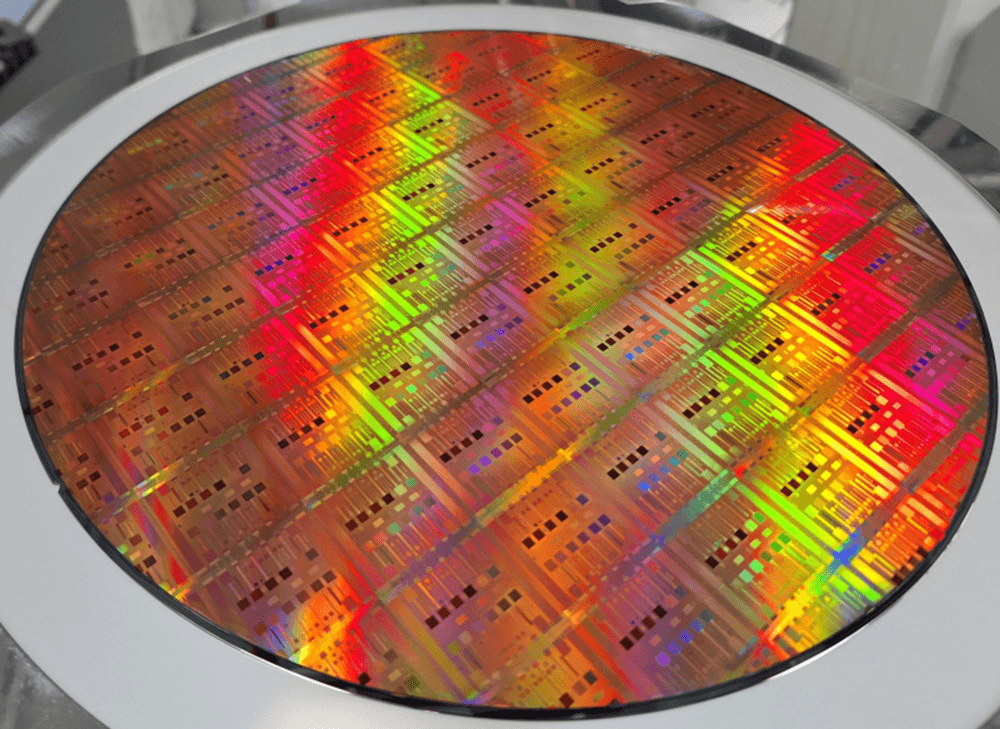

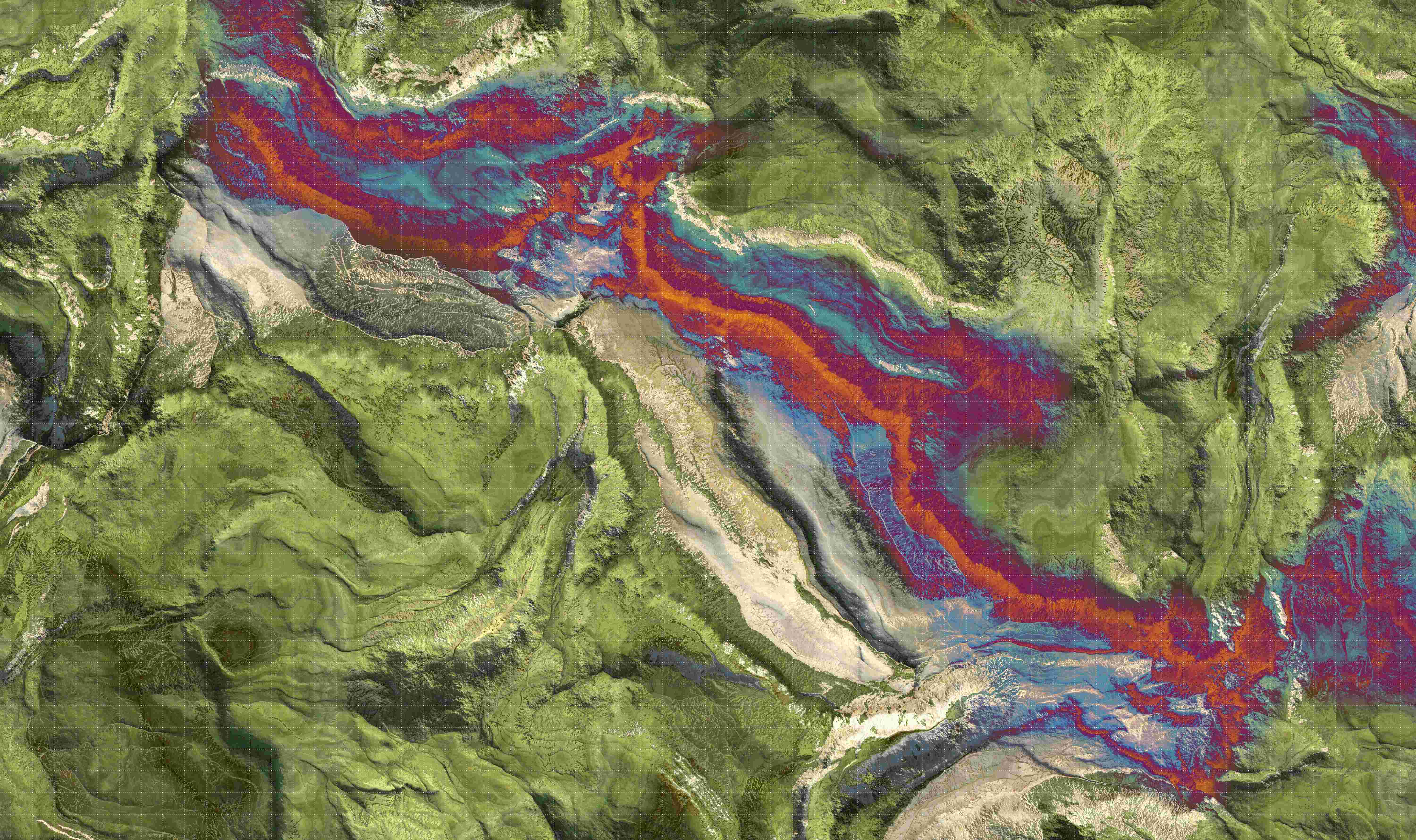

- Printed electronic foils in stretchable materials to fit with 3D-shaped polyurethane parts.

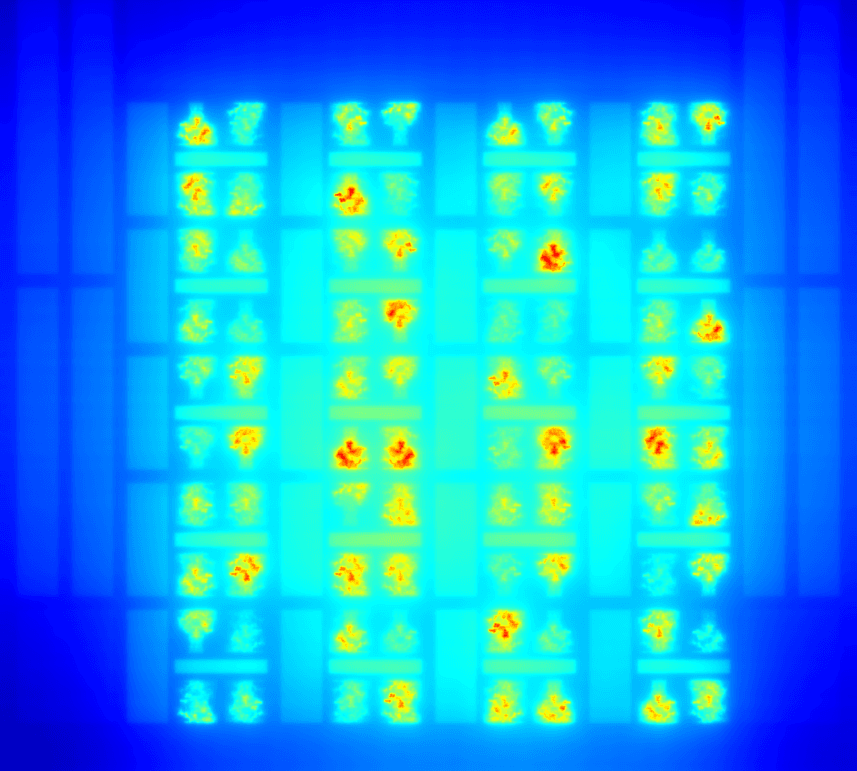

- Printed electronic foils with added components such as capacitive buttons and sliders, and proximity sensors combined with discrete components such as LEDs, actuators, or light guiding materials.

Research goals and innovation

To succeed in advancing such a new technology platform, the project will need to make breakthroughs in a number of fields:

- Substrate technologies – using new combinations of substrates and conductive inks.

- Assembly processes – combining and connecting soft foils and electronics in a way that adheres to automotive standards.

- Integrating light – defining strategies for using light and developing a balance between emitted light and integration into soft surfaces.

- Polyurethane spraying – a major leap to be taken is to integrate electronics, taking into account the strict specifications for functionality, esthetics and reliability.

One result of the project will be a demonstrator, an automotive interior that contains invisible integrated functional electronics and adheres to the specifications for automotive electronics.

“The project partners expect to gain a considerable expertise from this project, allowing them a direct valorization as suppliers to the automotive industry. In addition, the technology will also be applicable for other market segments including sport, healthcare and home interiors.”

Video

SASS

Integration of printed electronics functionalities in soft materials for automotive applications.

SASS is an imec.icon research project funded by imec and Agentschap Innoveren & Ondernemen (VLAIO).

The project has started on 01.10.2020 and is set to run until 30.09.2022.

Project information

Industry

- Connect Group

- Recticel UREPP Belgium

- Quad Industries

Research

- imec – CMST – Ugent

- KU Leuven – ESAT-TELEMIC

Contact

- Project lead: Yvan Vanluchene

- Research lead: Frederick Bossuyt

- Proposal manager: Frederick Bossuyt

- Innovation manager: Annelies Vandamme