How does it work?

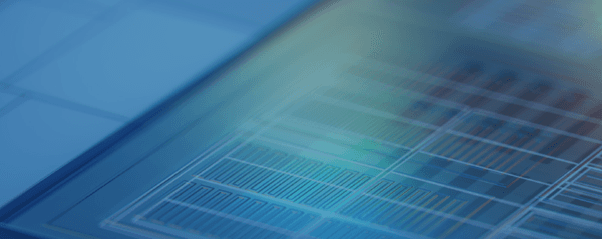

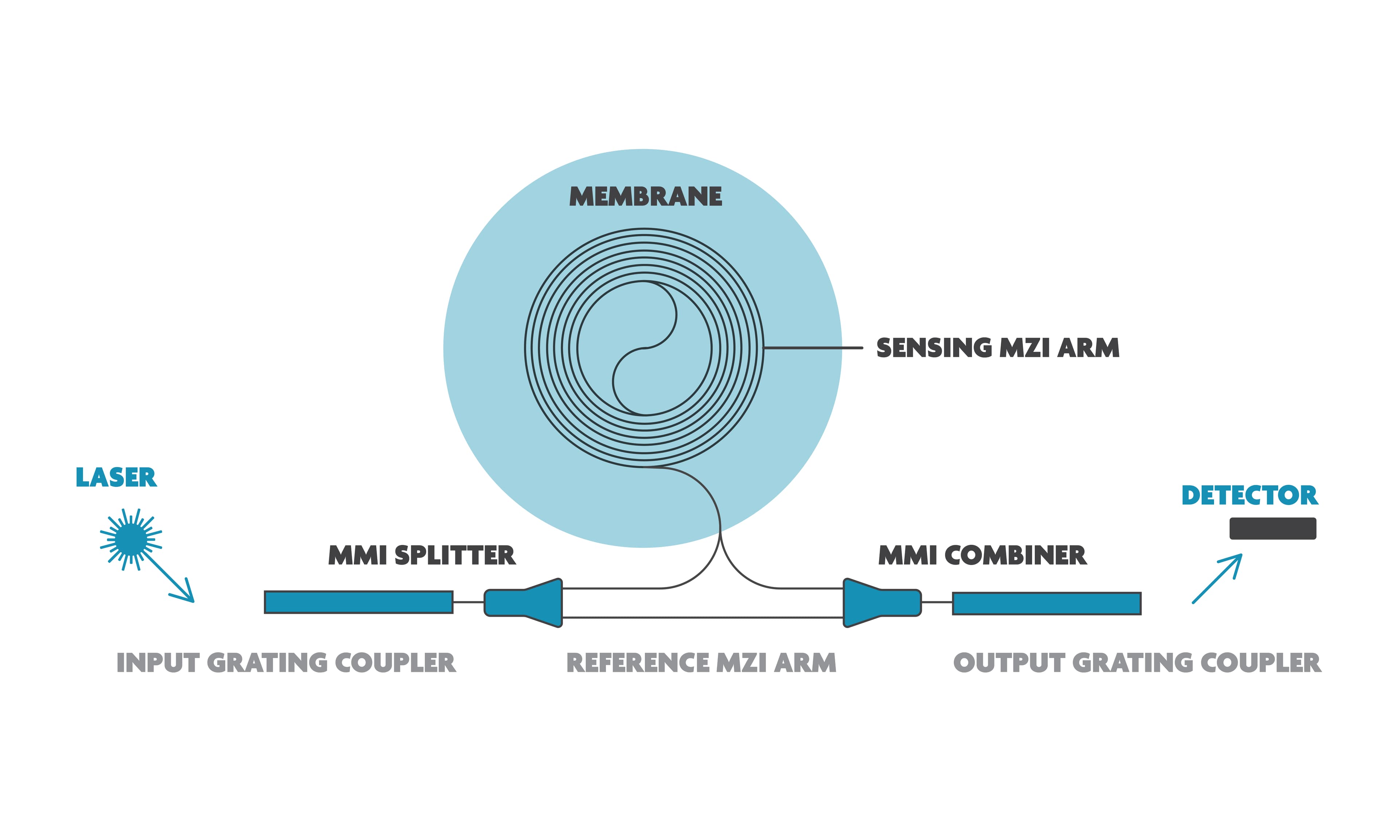

At the end of 2017, imec presented a pressure sensor based on MOMS technology (MOMS = micro-optomechanical systems). In short, it’s a sensor that converts the mechanical movement of a membrane (on micrometer scale) into an optical signal. Which works as follows: an optical circuit, e.g., a long waveguide, is built on a membrane. Subjected to a differential pressure stimulus, the membrane deforms, thus modifying the properties of the optical circuit, e.g., the phase of the light emerging from a long waveguide. By optically reading out this phase shift, one can determine the pressure that was initially applied to the sensor.

The deflection of a membrane carrying an optical waveguide causes a phase shift of an optical wave and allows to calculate the applied pressure.

What can it be used for?

Two major categories of advanced pressure sensors exist in the industry: MEMS sensors and photonic sensors. Pressure sensors based on MEMS technology (micro-electromechanical systems) have a similar mechanical detection principle (deflection of a membrane), but combined with an electrical readout (changing properties of an electric current). Because of their miniaturization and performance, they are well established in areas such as the automotive and medical industry, height- and depth-measurements and flow sensing. Photonic sensors use the changing properties of an optical wave when passing through a material that’s being strained. They are popular because of their higher sensitivity and lower noise, but are not available in miniaturized and integrated systems. With MOMS technology, imec makes sensors that have the same performance as the photonic sensors and the small size of MEMS sensors. They combine great accuracy and linearity with a wide dynamic range and thus the best of two worlds.

Searching for the most demanding application

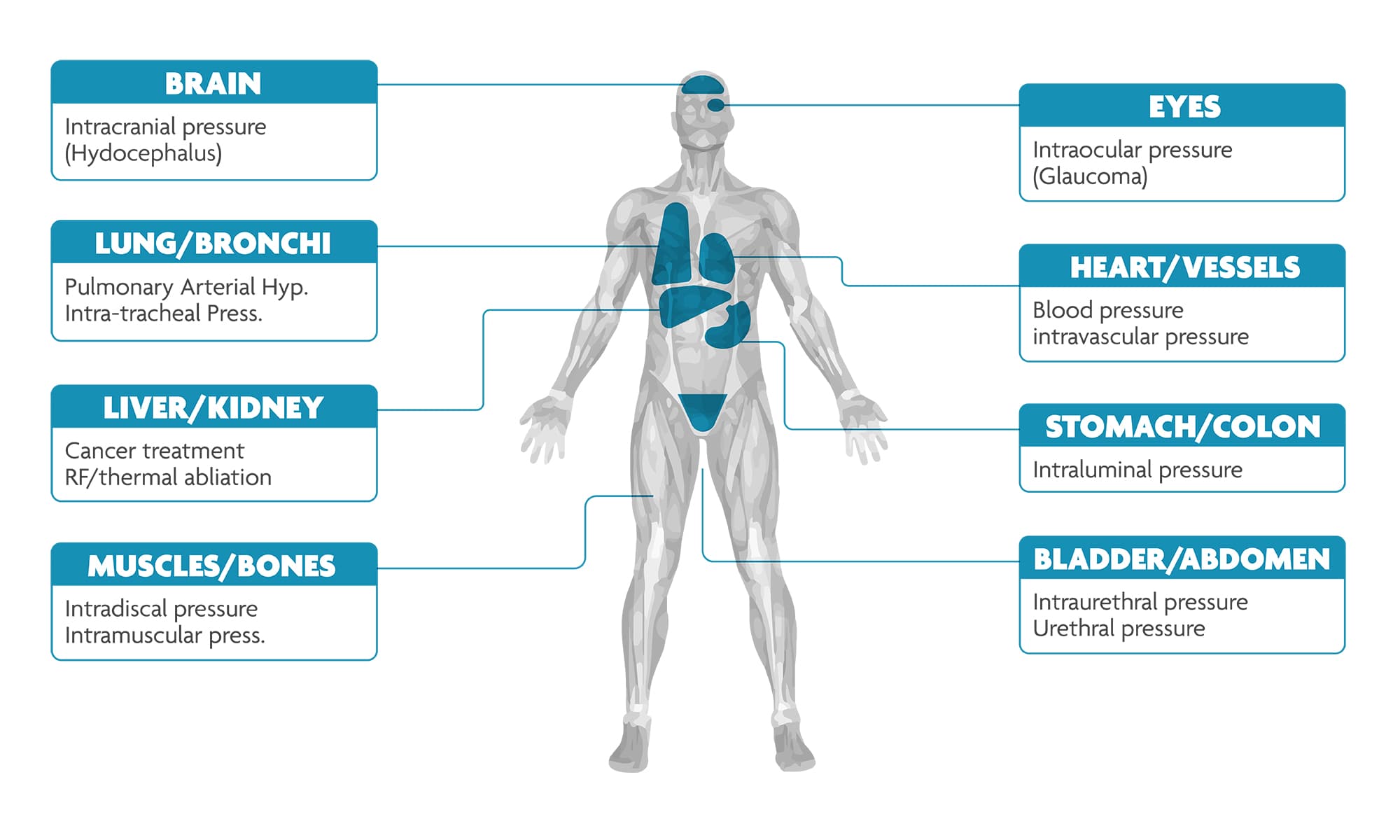

For several reasons, imec sees potential in MOMS. First because a small mechanical deflection in the sensor can induce a large optical effect and thus results in a high sensitivity. Secondly, the MOMS sensors do not contain metals, which makes them particularly interesting for medical applications. Think of sensors that are compatible with magnetic systems such as an MRI-scanner. Also, their biocompatibility has already been proven, so they are potentially suitable for implants, such as detecting intracranial pressure.

The imec sensor is radiation-hard and biocompatible, so it is extremely suitable for potential medical applications.

Another advantage of MOMS is that the mechanical movement and the optical reading are decoupled and independent from electric currents. It makes MOMS radiation-hard and insensitive to electromagnetic interference. And at least as important: it allows massive multiplexing: the parallel readout of an unprecedented number of sensors via an optical bus, not requiring integrated support electronics. Imec reaches out to industry to jointly find the killer application that would require such performance. For example, for the existing vision of a surgical glove with thousands of integrated MOMS sensors, which can be used for haptic detection of tumors.

Increasing popularity

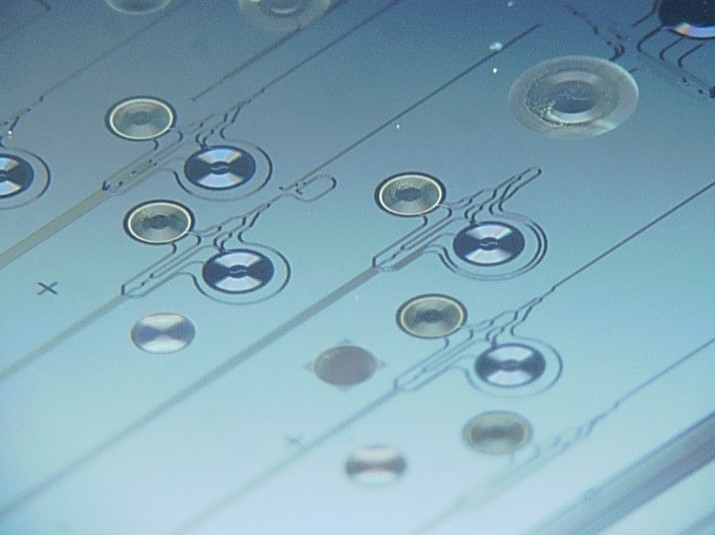

MOMS technology, however, is not new. First references in scientific literature date back to the nineties. Nevertheless, the technology is still in its infancy. Largely because advanced miniaturization and process technology are required for MOMS to reach their full potential compared to classic photonic sensors. It is therefore no coincidence that in recent years the popularity of MOMS has increased in parallel with accelerated developments in the area of photonics. At least, this is what happened at imec, where research on MOMS started a few years ago, by combining imec's robust SiN-based photonics platform with the imec expertise in MEMS technologies. Meanwhile, MOMS have their own process flow in the imec pilot line, based on low-temperature SiN deposition (PECVD) and 200 mm deep UV lithography. This level of process integration improves the quality of the sensors and also allows post-processing on optical imagers. But the biggest gain in performance of imec’s MOMS sensor came from its design.

Smart system design

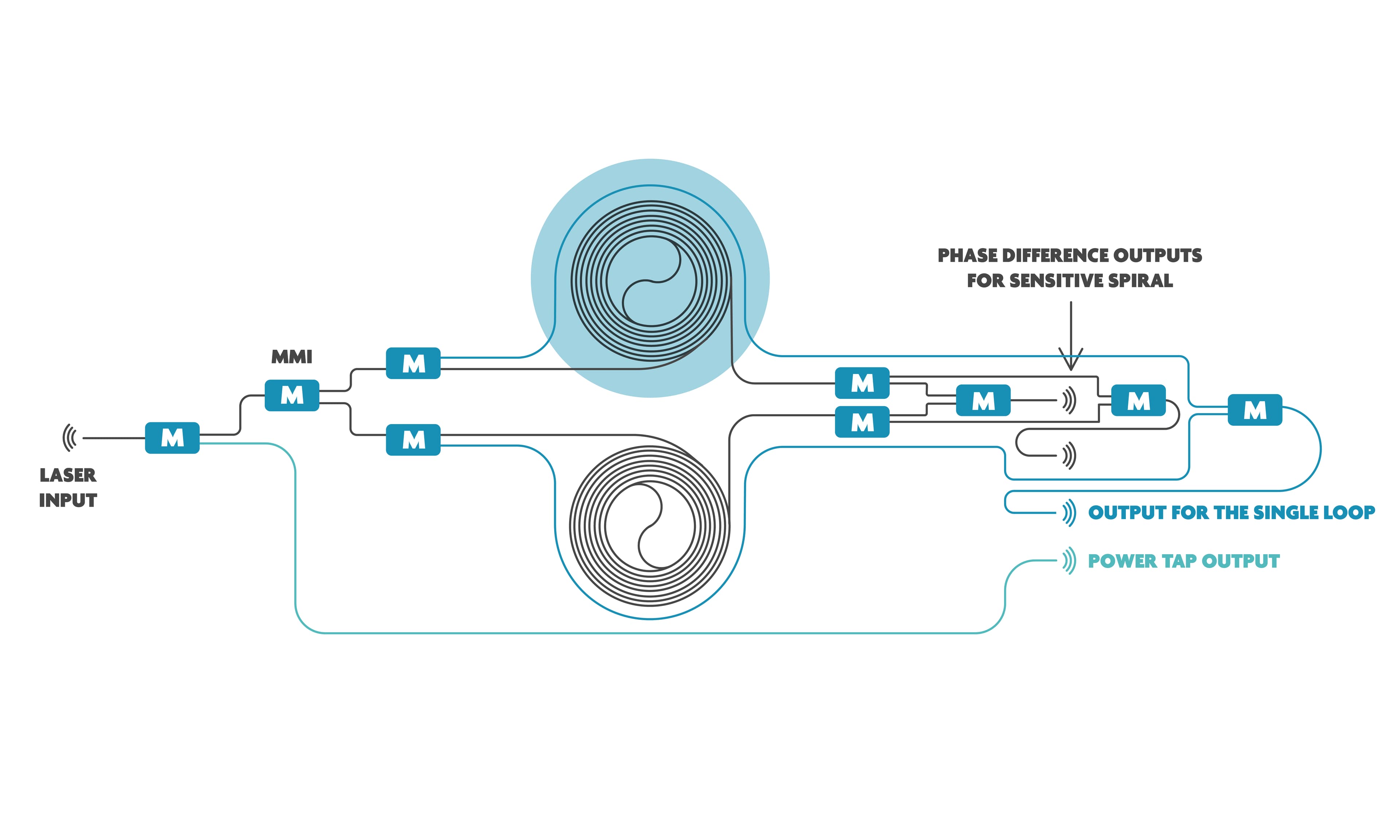

The common way to design a MOMS pressure sensor is based on Mach-Zehnder Interferometers (MZI) or ring resonators. Imec applied a clever approach to the design of the MZI, giving them a wider range thanks to the number of loops and their shapes.

From top to bottom: Classic MZI design and the new design by imec (scheme and photo), in which multiple loops of different shapes result in a high sensitivity across a wide range.

Adding loops increases the sensitivity of the sensor but decreases its unambiguous measurement range. The imec design therefore combines short (single loop) and long spiral waveguides on a single membrane. By cleverly combining the signals from both waveguides, the imec sensors maintain a high sensitivity and a wide range. First measurements indicate a standard deviation of less than 1Pa at a range that can go beyond 100kPa, which is similar to commercial sensors, but without the electromagnetic sensitivity of MEMS sensors and in a smaller form factor than typical photonic sensors.

The future

For imec, the pressure sensor is a first example of how MOMS technology can complement MEMS and photonic sensors. The aim is to eventually develop a robust MOMS platform with a wide range of sensors.

At the same time, imec is reaching out to industry to discover in which applications the sensor’s high performance and broad applicability can prove their added value.

Want to know more?

- End 2017 imec issued a press release on a MOMS pressure sensor.

Xavier Rottenberg is scientific director and group leader wave-based sensors and actuators at imec. He received the MSc degree in Physics Engineering and a supplementary degree in Theoretical Physics in 1998 and 1999 from "Université Libre de Bruxelles", Belgium. He received further his PhD degree in Electrical Engineering in 2008 from KU Leuven, Belgium. He worked one year at the Royal Meteorological Institute of Belgium in the field of remote sensing from space and joined imec in 2000.

Published on:

6 February 2019