Solid-state lidar technology

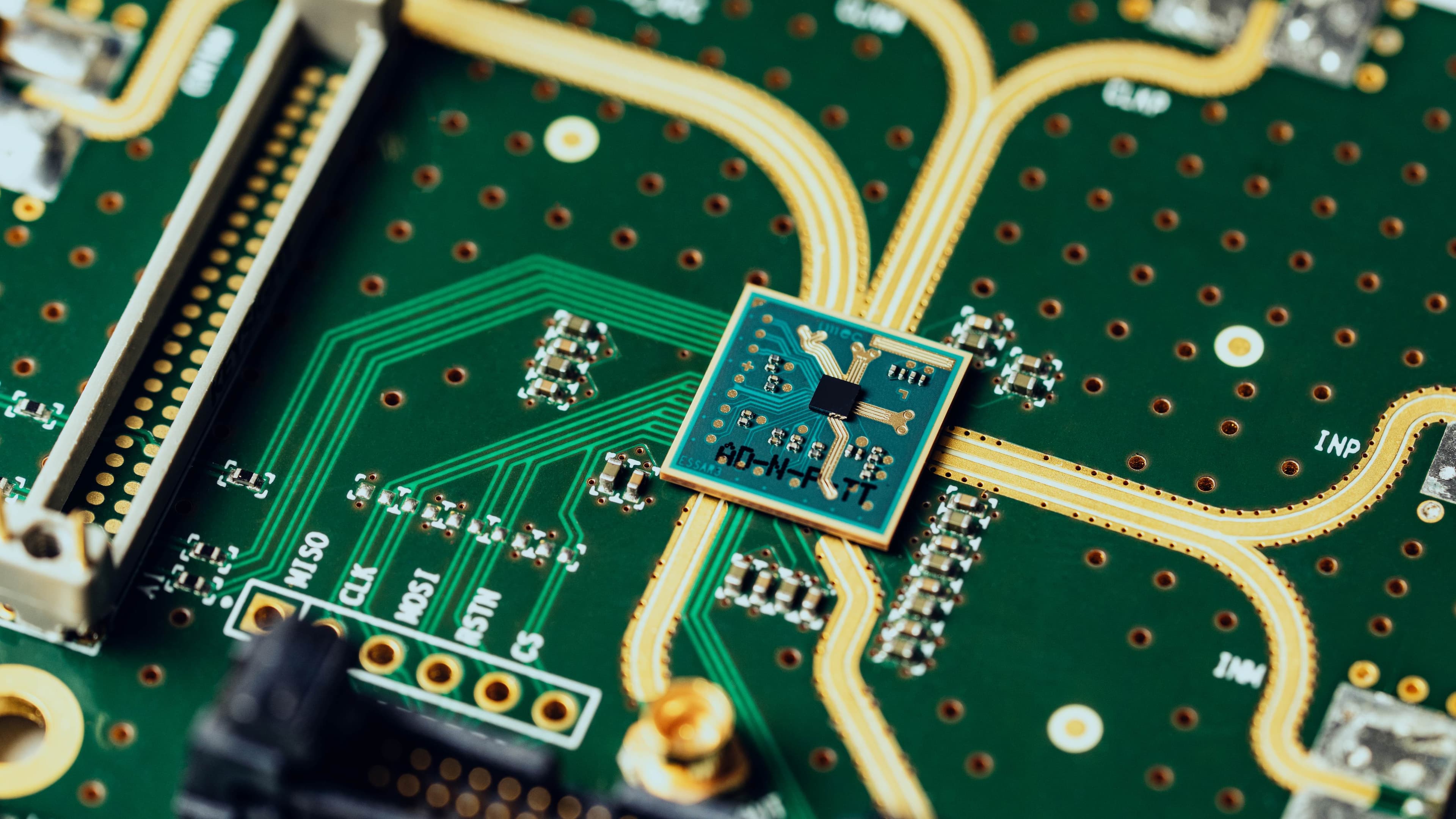

Use imec’s photonics platforms to develop your custom-made building blocks, such as optical phased arrays (OPA), for next generation on-chip LiDAR.

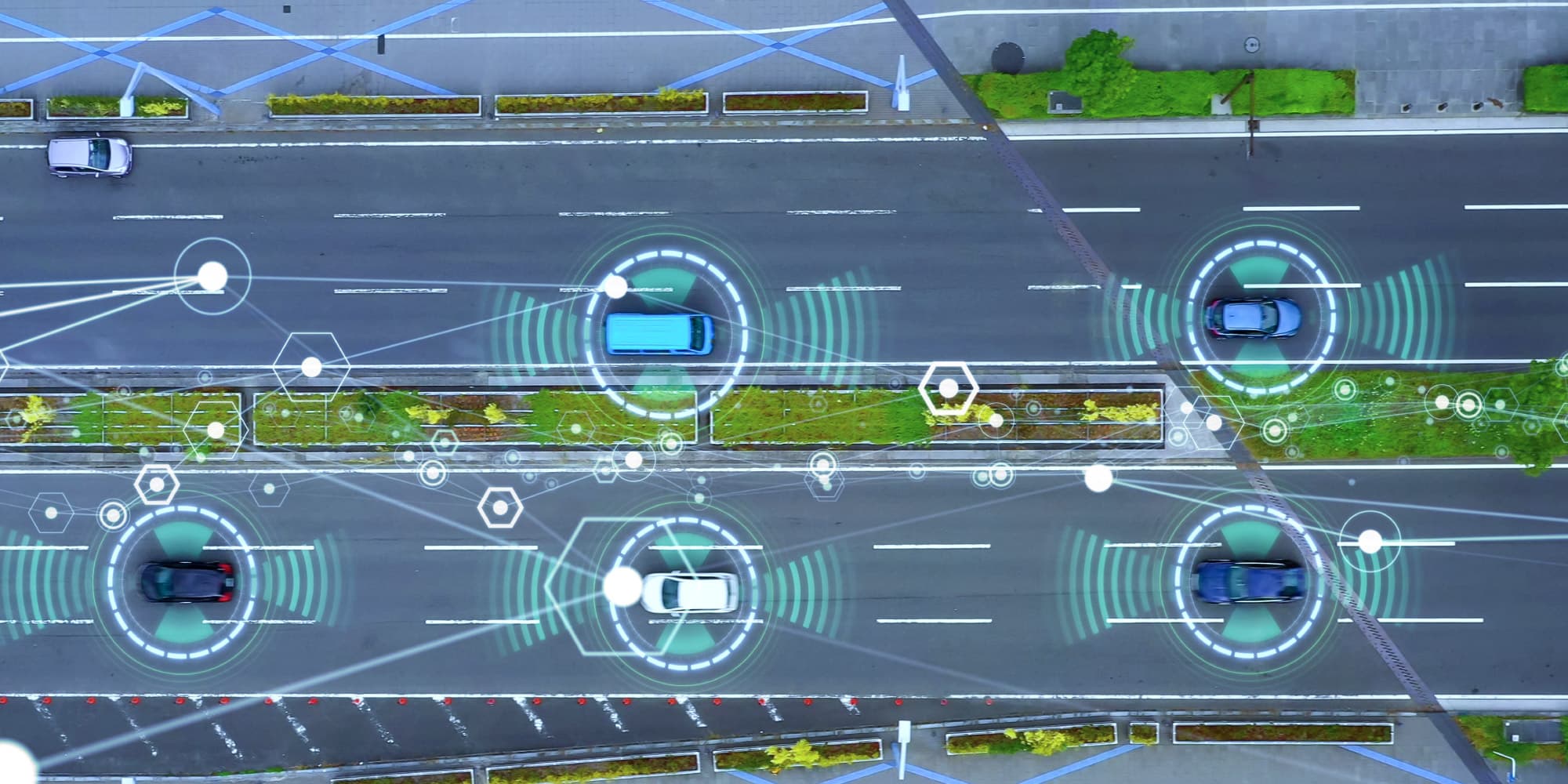

Solid-state lidar, a lidar system that has no need for moving parts, has been an exciting research topic for quite a while. And now it’s finding its way into commercial products.

Especially automotive applications, such as ADAS technologies, are craving compact, robust and inexpensive systems for 3D mapping of a car’s surroundings. Other applications for on-chip lidar are drone-enabled land surveying, robotics, wind monitoring, surveillance, and virtual reality.

Want to build your own solid-state lidar system? Tap into imec’s integrated photonics and optical beamforming platform to gain access to all the necessary building blocks.

Solid-state lidar vs. mechanical lidar

There are many reasons why today’s mechanical and hybrid (solid-state combined with mechanical) lidar technologies don’t meet the demands of tomorrow’s applications:

- They’re too bulky and costly for elegant integration into devices such as cars, VR devices and mobile lidar systems.

- They often depend on experts for their operation and calibration, which further adds to the price tag.

- They’re composed of moving parts, making them vulnerable to vibrations and shocks.

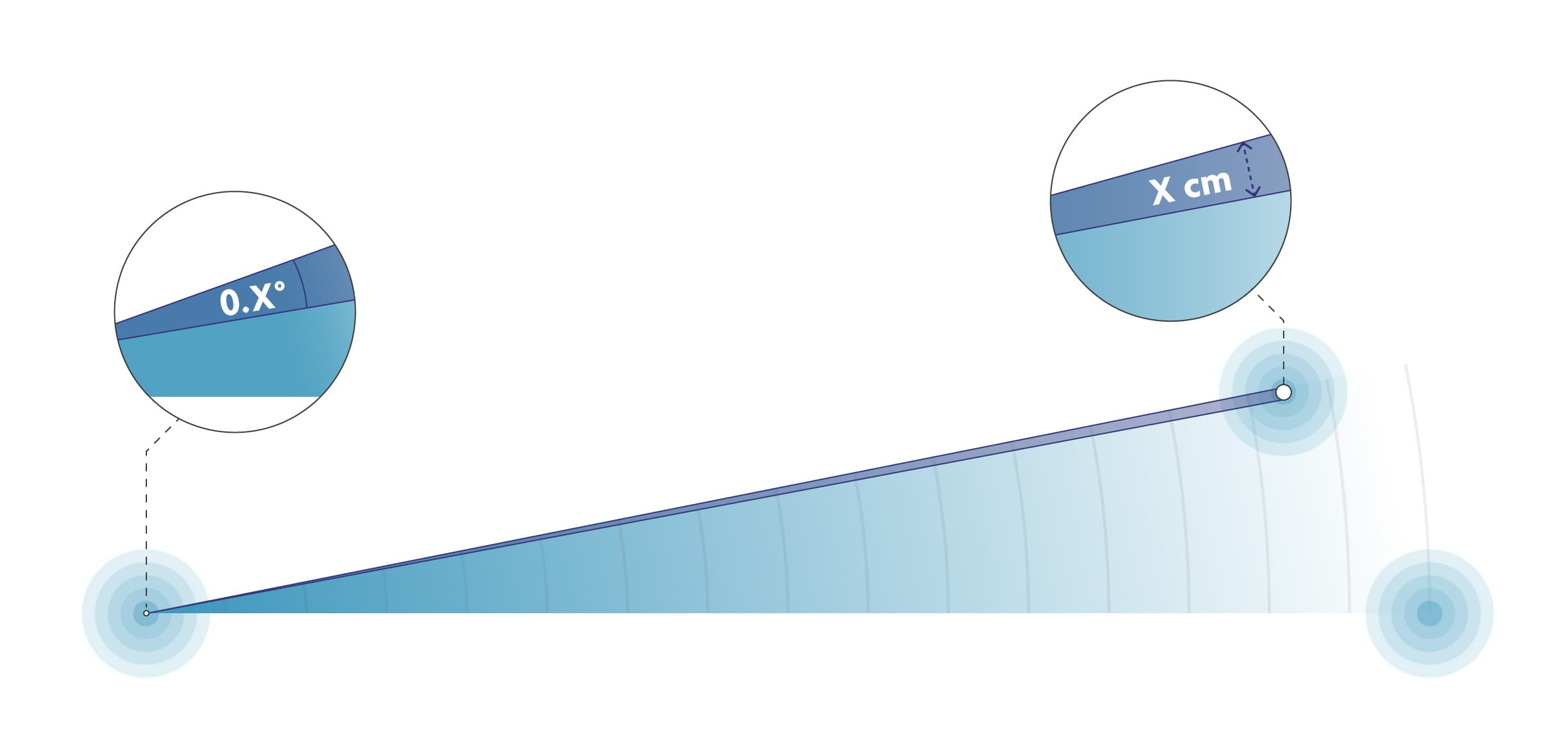

Moreover, the angular resolution of mechanical lidar does not meet the requirements needed for activities such as long-range scanning. For example: to resolve a cm-scale object from 200-300 m, you need an angular resolution in the order of 0.01°.

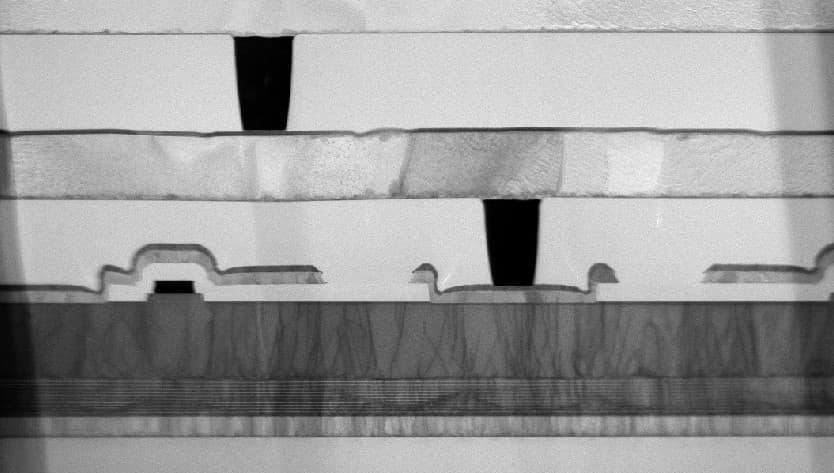

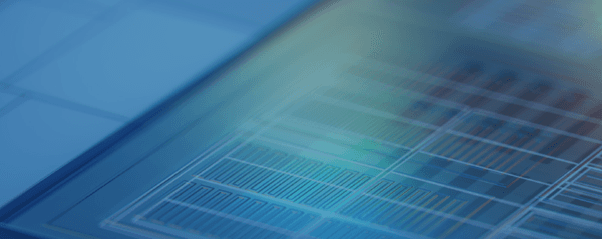

By integrating all lidar components on one integrated circuit, solid-state lidars overcome all these drawbacks. They’re compact, contain no moving parts, and can be mass-produced (wafer level) at a relatively low cost per device.

Only a solid-state lidar can direct a signal over a hundred meters of distance with an accuracy of a fraction of a degree.

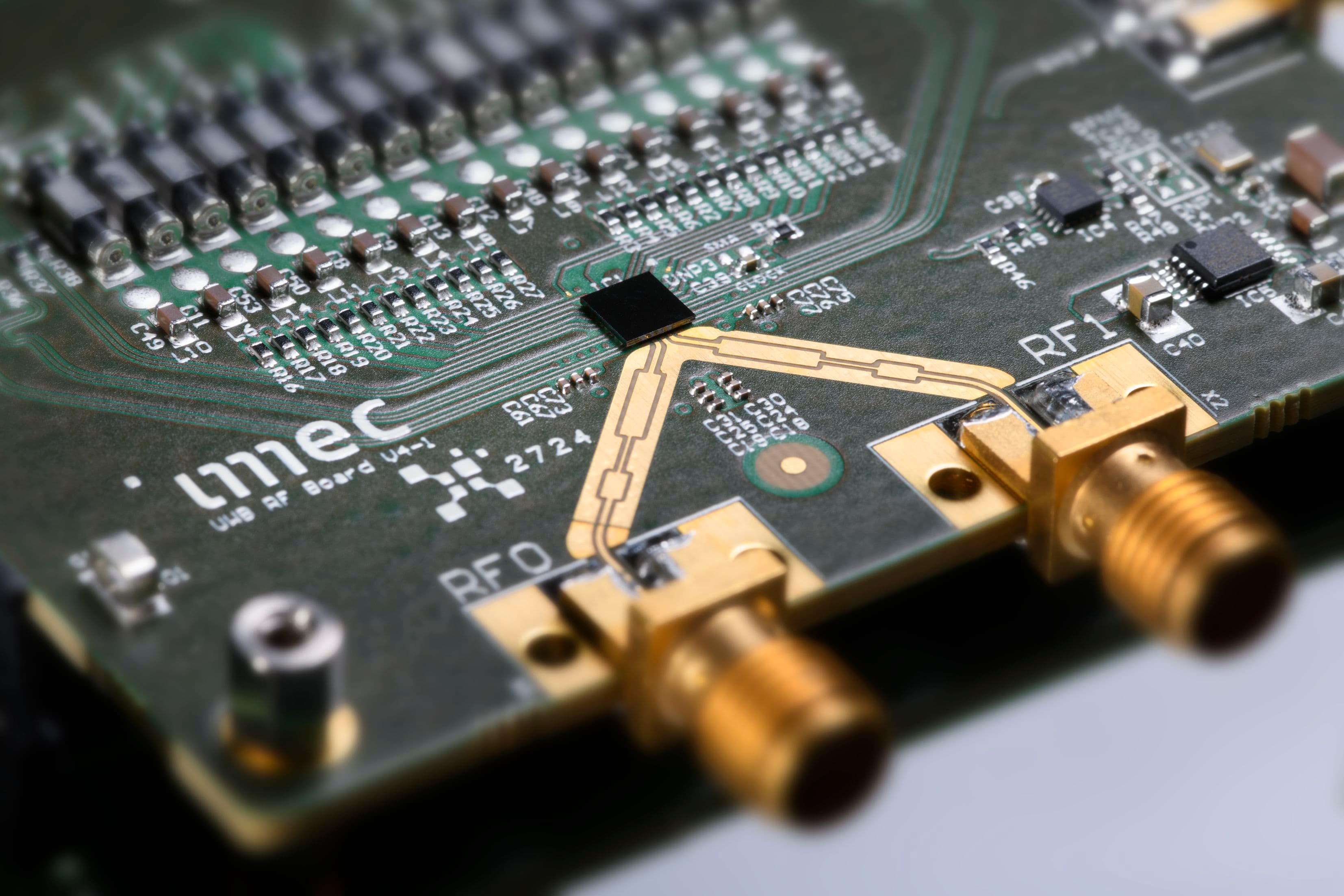

Imec’s building blocks for solid-state lidar

Whether you’re building a time of flight (ToF) or frequency-modulated continuous wave (FMCW) lidar system, imec’s generic platform offers you the mature building blocks you need. Both standalone SiN and SiN-on-SOI technologies combine:

- the high-power handling, low propagation loss, and low phase noise of SiN

- the efficient phase shifting, compact circuits, and integrated detectors of silicon

Explore this article for a deep dive into the technology. And this press release on our collaboration with Scantinel.

Moreover, imec’s solid-state lidar technology uses an on-chip detector array to ease the calibration without looking at the far field. This capability for on-chip calibration will reduce the complexity and maintenance cost of your lidar system even more.

This project received funding from the PhotonDelta National Growth Fund program.

Want to work with us on your next-generation lidar application? Get in touch for access to imec's building blocks and expertise, including electronics, algorithms, IC/circuit and system design.