Nano-optics

Want to integrate nanoscale optical components in your innovative products such as cameras, displays or sensor systems? Imec helps you with the full development process.

For centuries, optical instruments remained bulky and expensive. They were produced by refining mechanical parts, usually in glass, that manipulate the light in order to sense, measure, make projections, ...

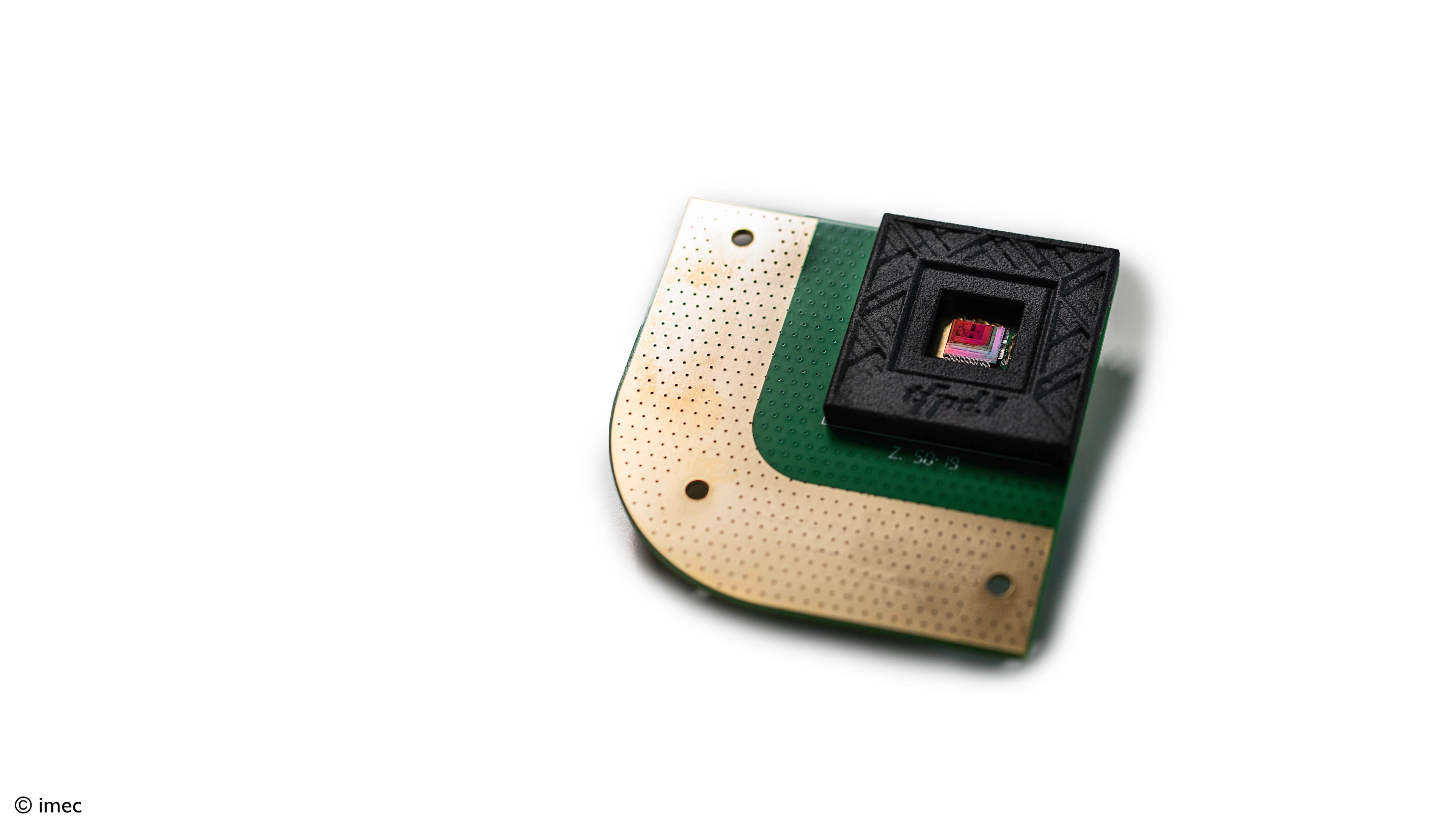

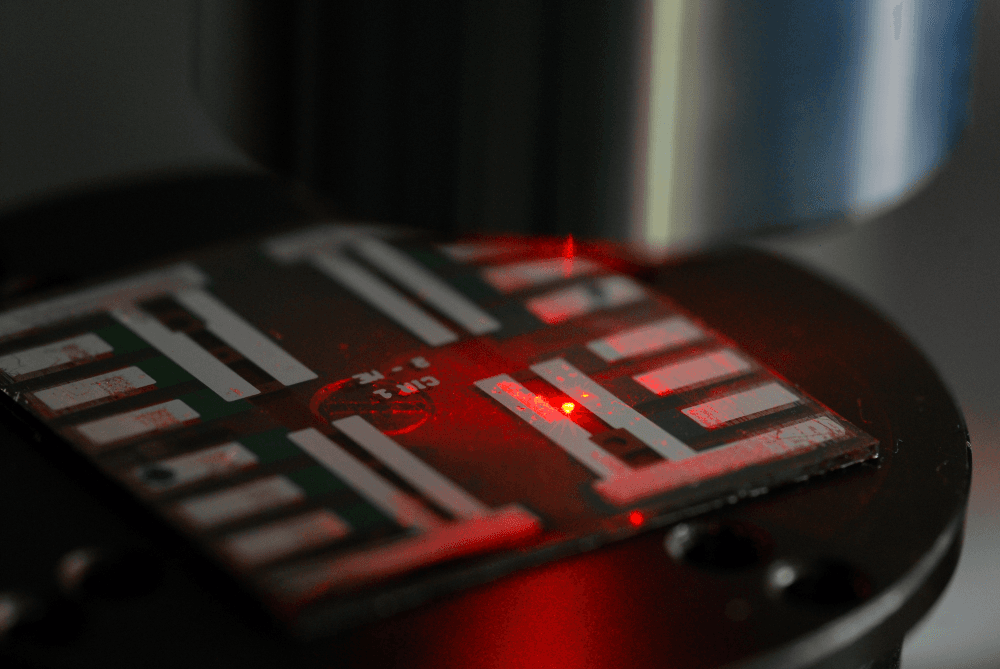

It’s only recently that there’s an alternative for this traditional approach: nano-optics delves into the toolbox of the semiconductor industry. The idea is to create nanostructures that fulfill optical functions. Examples of such functions are focusing and color splitting – at a wavelength scale and with visible as well as infra-red light.

Want to dive into this toolbox? Imec is ready to help you with the development and integration of such nano-optics components in its state-of-the art cleanrooms. And we can guide you towards large-scale manufacturing.

Advantages of nano-optics

The main advantage of nano-optics? Its compactness compared to traditional macro-optics. Moreover, nano-optics (or flat optics) components are processed using well-established techniques from the microchip industry, such as lithography and thin-film deposition. The result is that manufacturing becomes cheaper and easier to upscale.

Some other advantages of nano-optics are:

- They exhibit high design flexibility and material flexibility.

- They can be perfectly alignmed and optimized at pixel level.

- They're compatible with further post processing on complex integrated circuits.

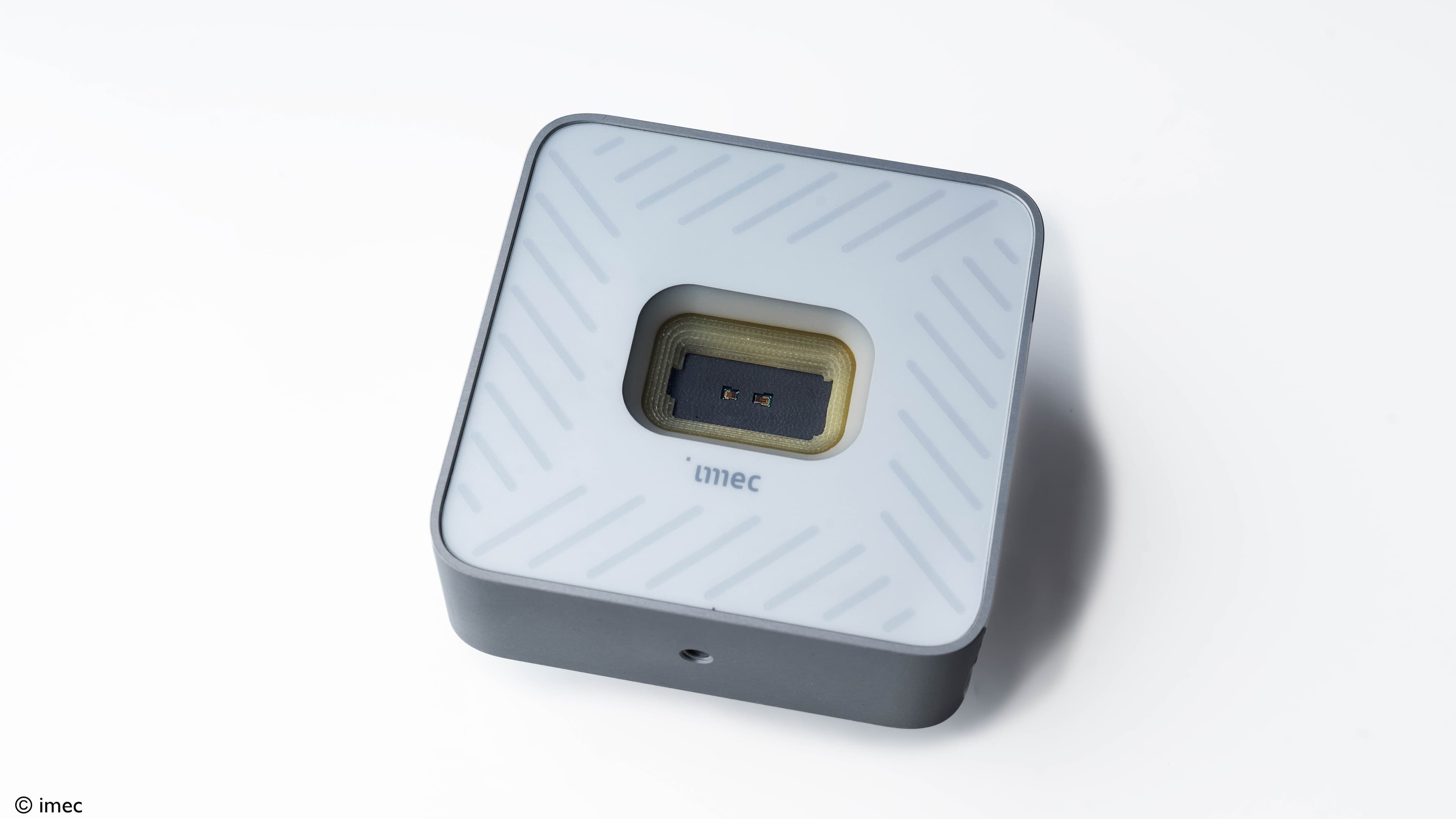

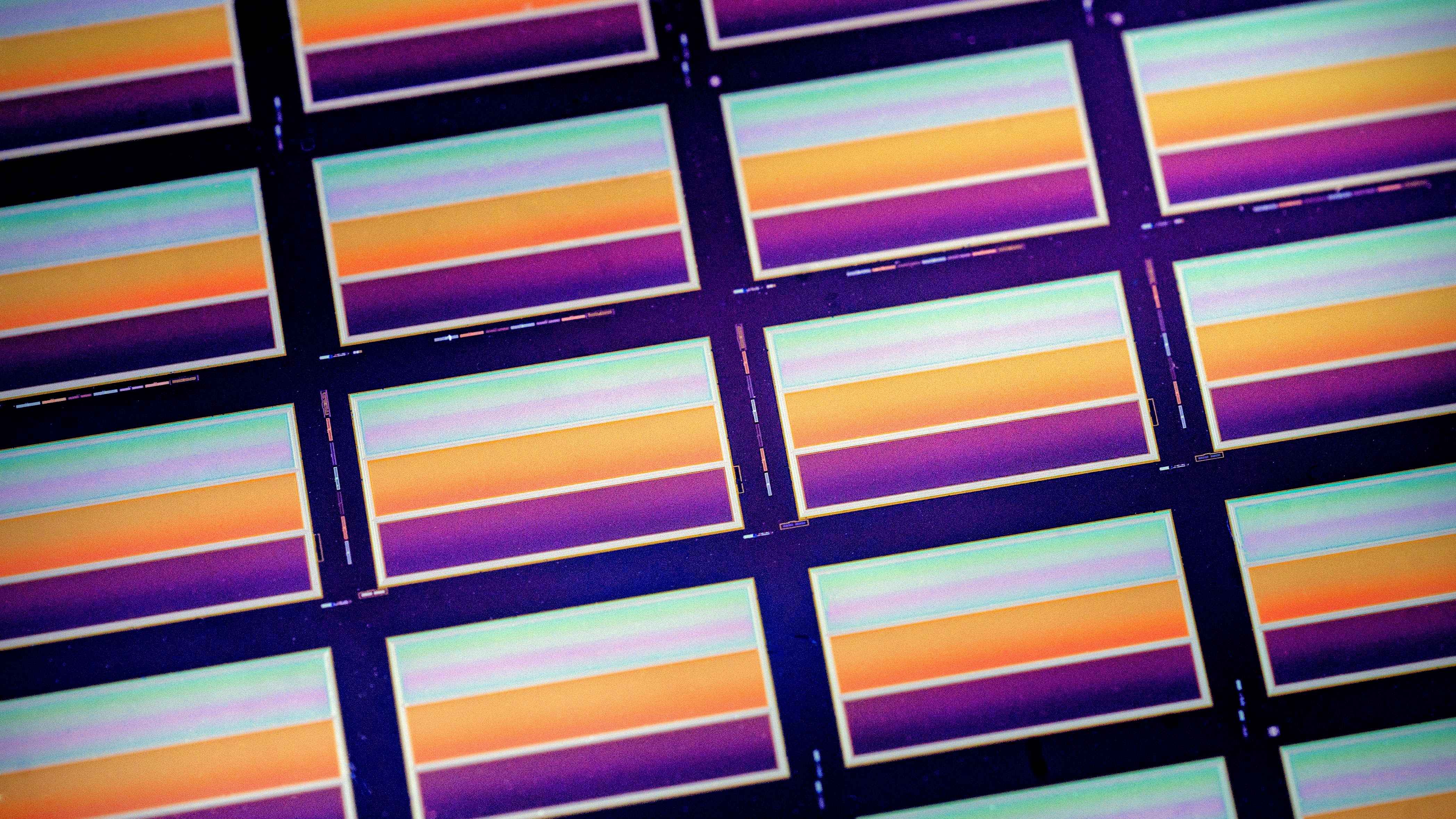

Nano-ptics processed on 200-mm/8-inch quartz in imec’s CMOS line

Applications

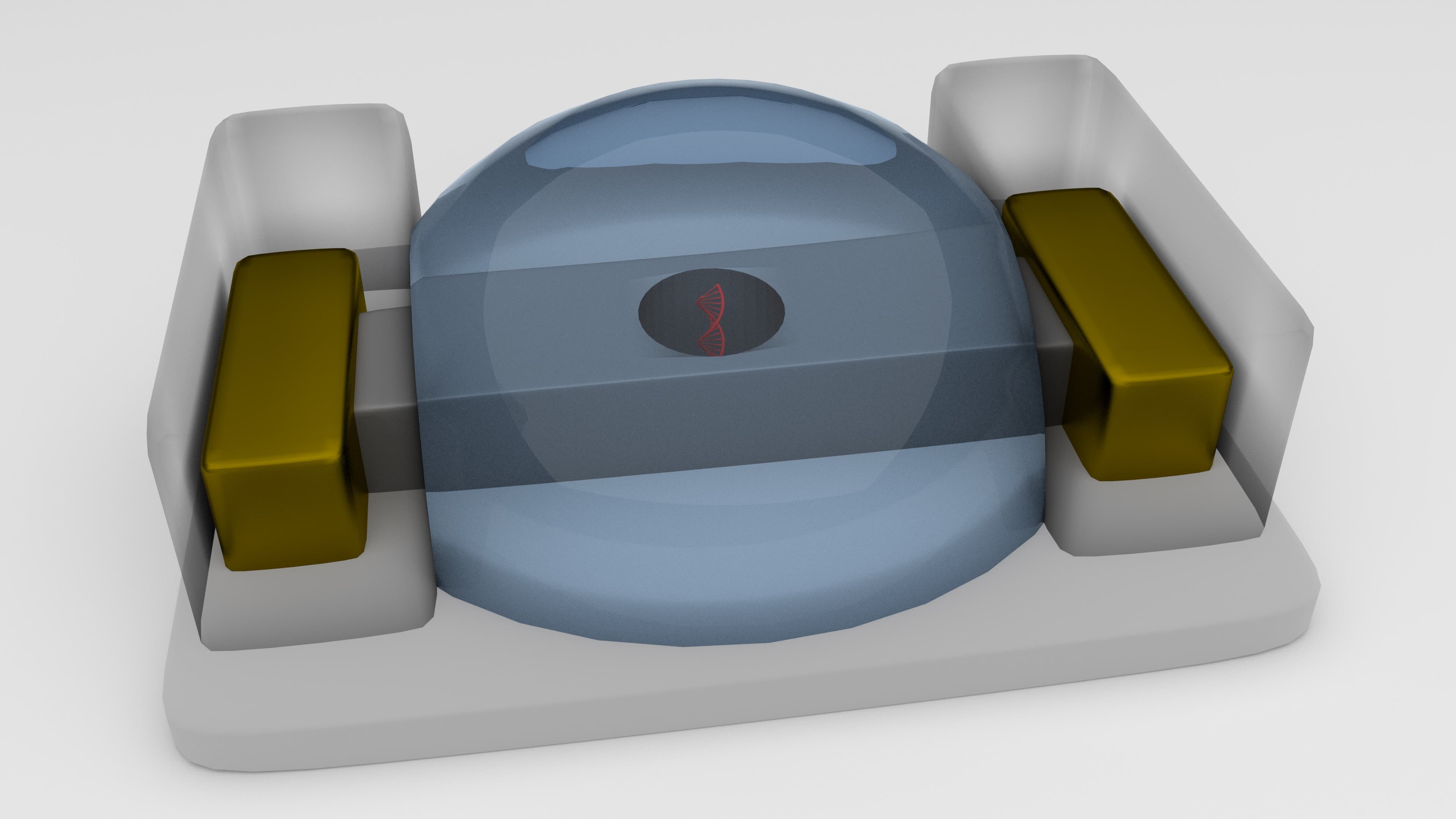

The miniaturization of optical components enables their integration into complex systems-on-chip. This opens the door to product innovations in markets such as:

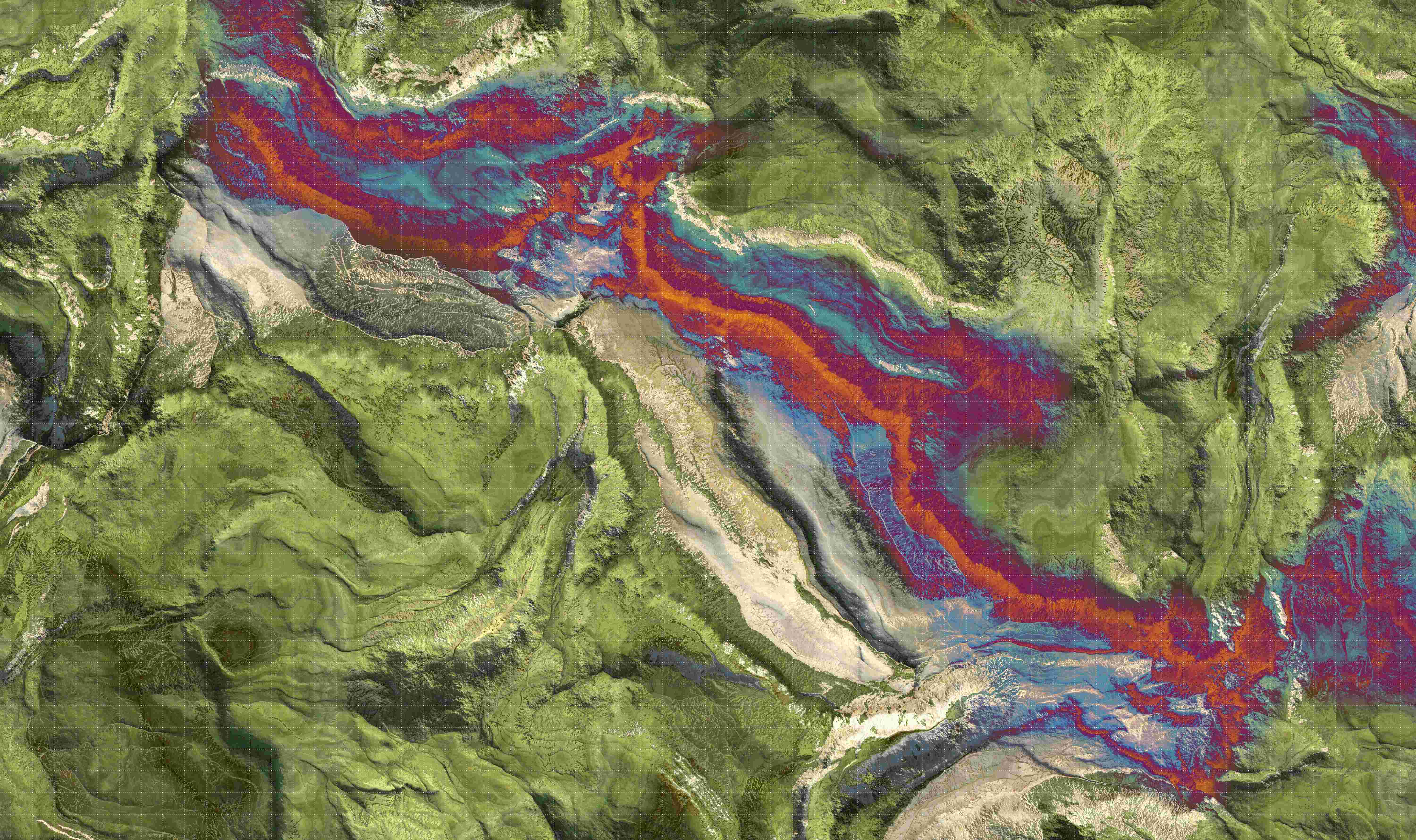

- cameras: 3D, light pipes, spectral imaging, ...

- displays: directive, 3D, microLEDs, ...

- glasses: mirrors, diffusers, scatters, ...

- sensors: spectrometers-on-chip, fluorescence imaging, sorting, ...

Develop your nano-optics components with imec

At imec, we support the full development of flat optics components such as filters, polarizers and lenses. Based on your requests, we:

- Assess the feasibility of your flat optics component.

- Design the component and develop the process.

- Realize a first prototype.

- Optimize the design and process technology

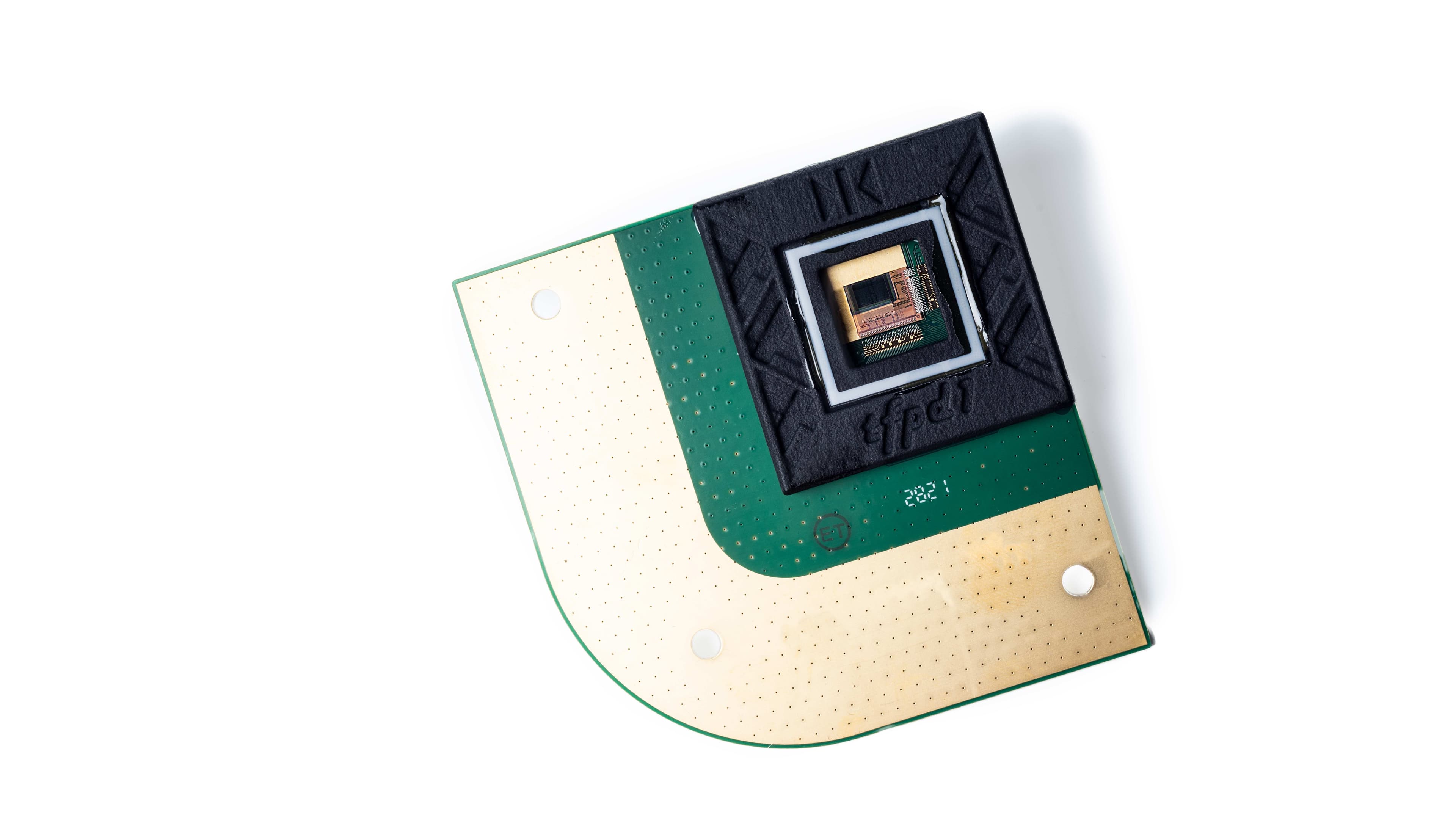

In our 200- and 300-mm cleanrooms, we're able to:

- Process on glass for standalone applications.

- Post-process on top of device wafers for integrated applications.

Are you ready to work with us?