Build your GaN-ICs with imec’s GaN-on-SOI MPW process

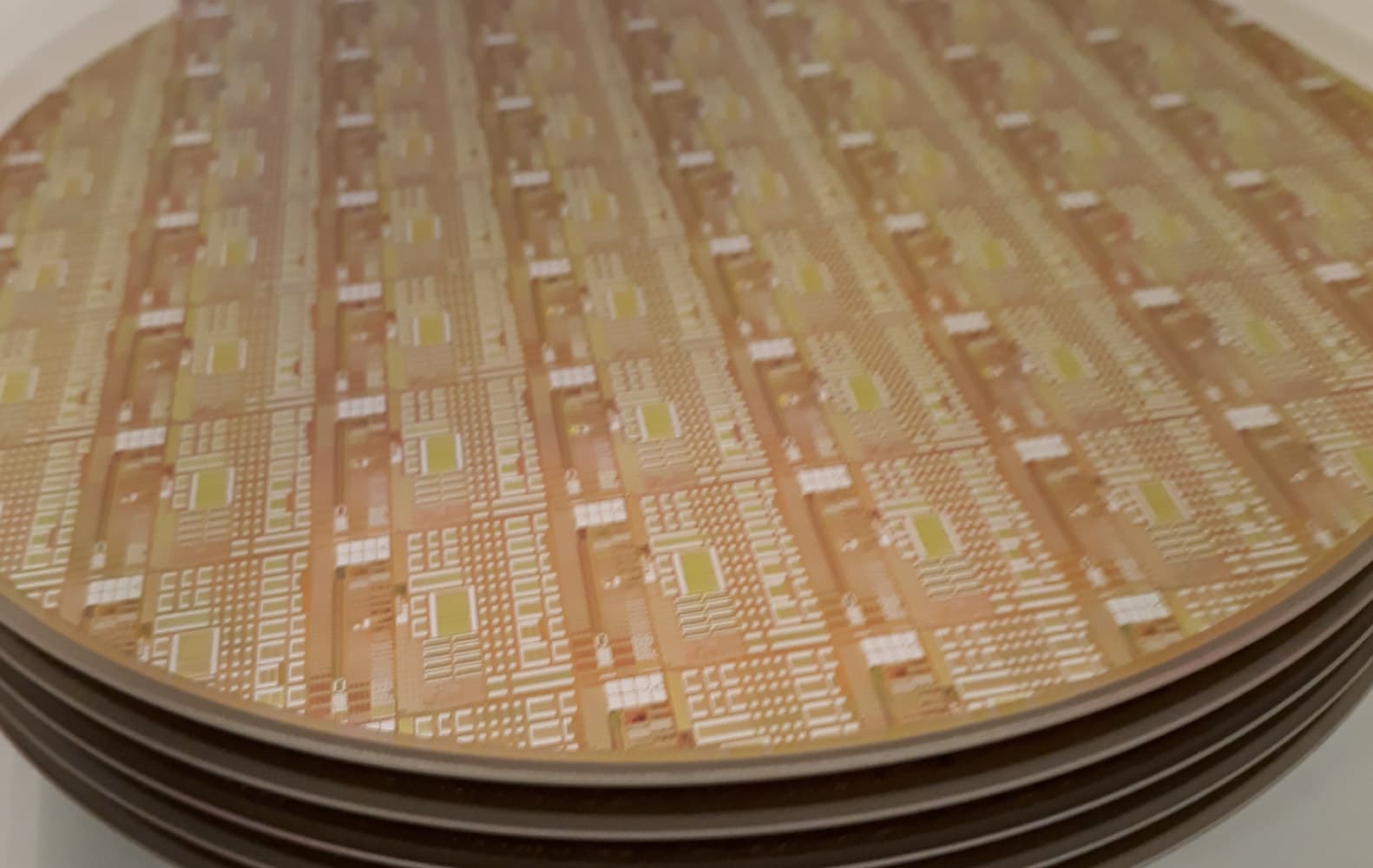

The advantages of GaN (gallium nitride) as a power conductor are increasingly obvious. So is the need to integrate GaN power devices on a single chip. Imec tackles that challenge with its unique GaN-on-SOI process. And it’s affordable to you thanks to imec’s Multi-Project Wafer service (MPW).

GaN-ICs unlock the full potential of GaN power electronics

Most current GaN-based power systems are multi-chip solutions: different components are assembled on a PCB. Not ideal, because maximum switching speeds don’t even come close to their potential values.

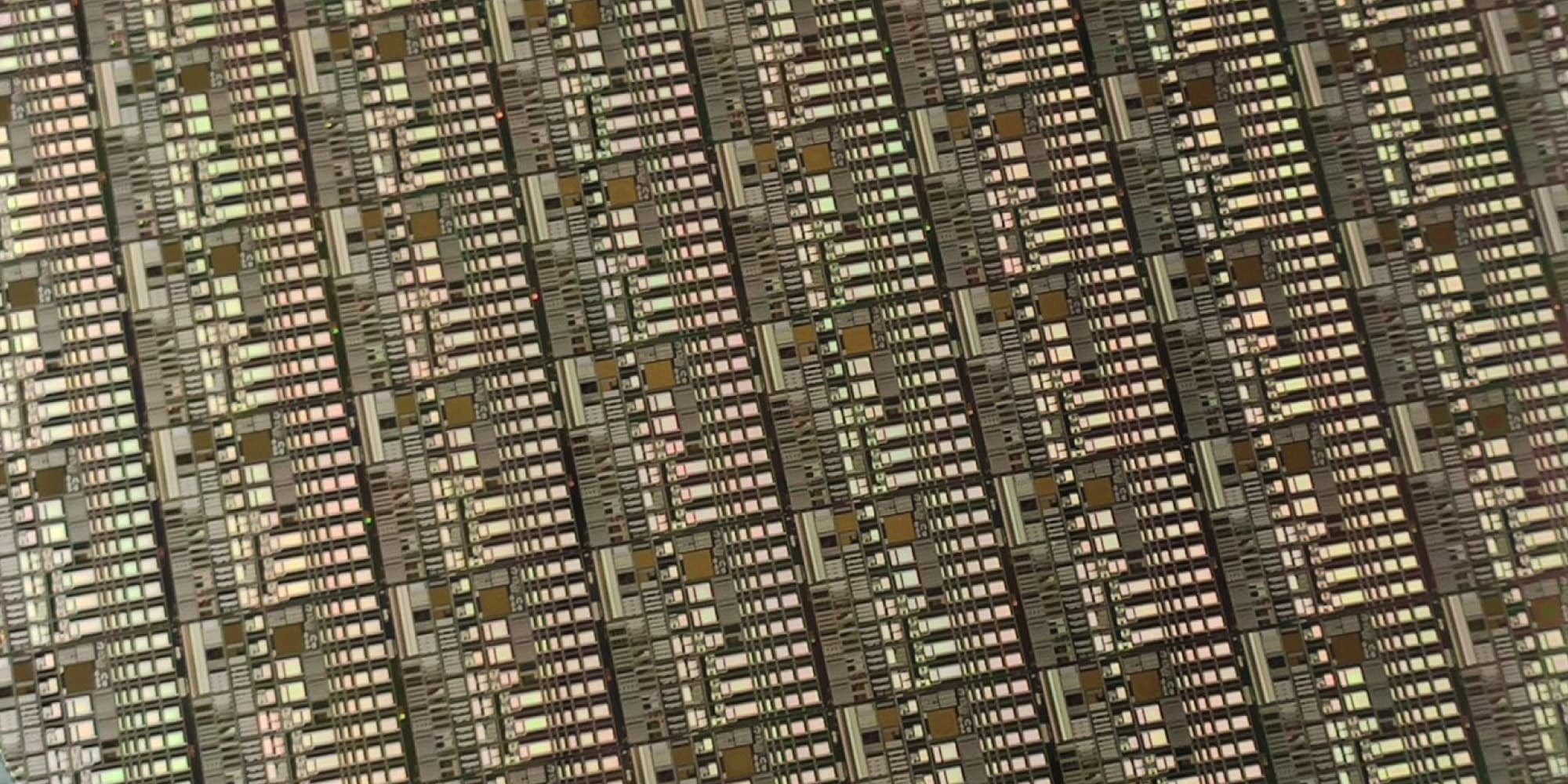

The better solution is to combine these components on one complex GaN-IC. That allows you to:

- minimize form factors

- increase switching speeds

- save on packaging costs

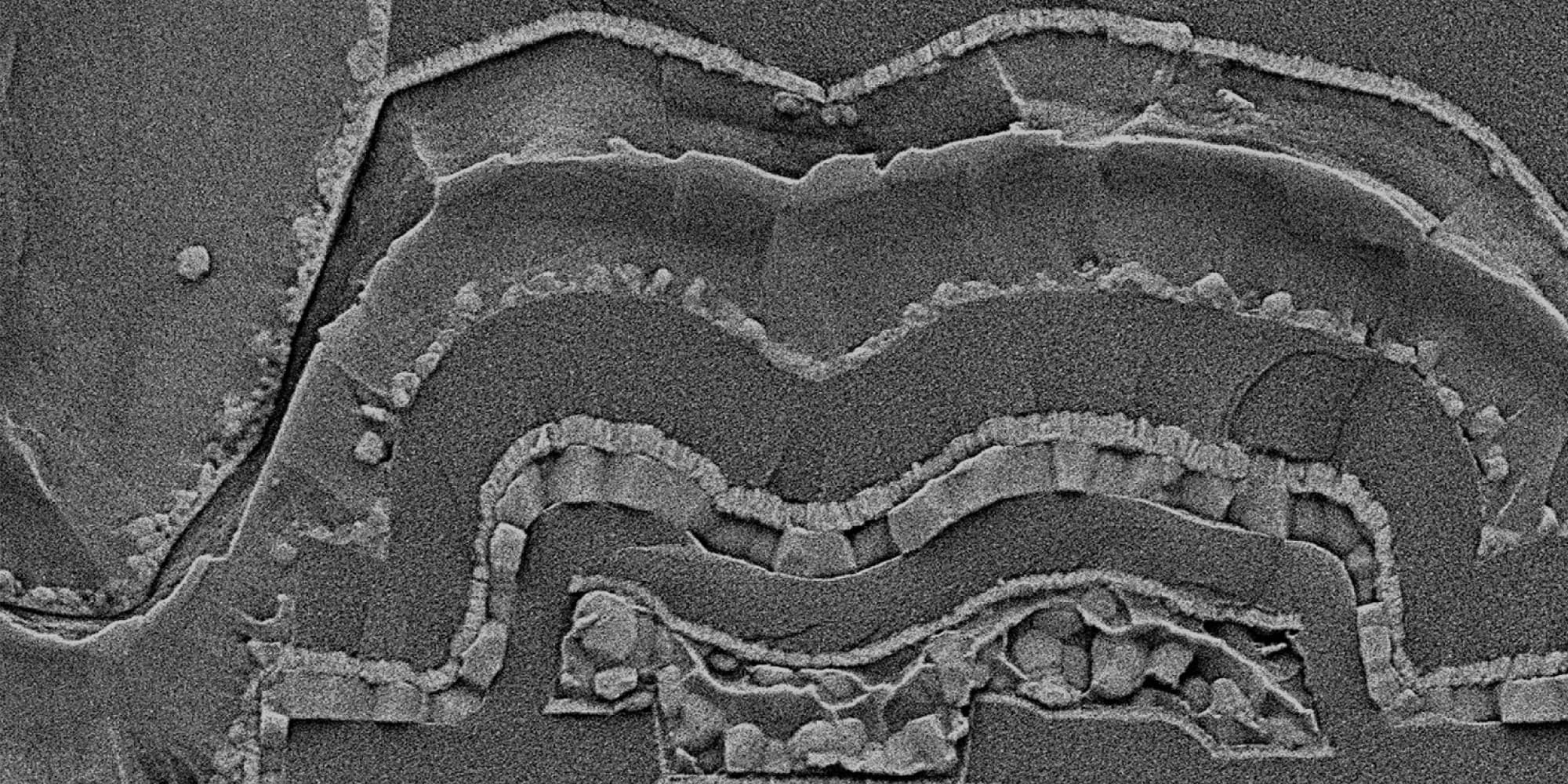

So how do you tackle that monolithic integration? The biggest challenge is the lateral isolation of the devices to minimize parasitic inductance. In GaN-on-Si devices, that’s achieved by an isolation implant or a mesa etching process. Not ideal, because the devices still share a common conductive Si substrate, which can only be referenced to a single potential at a time.

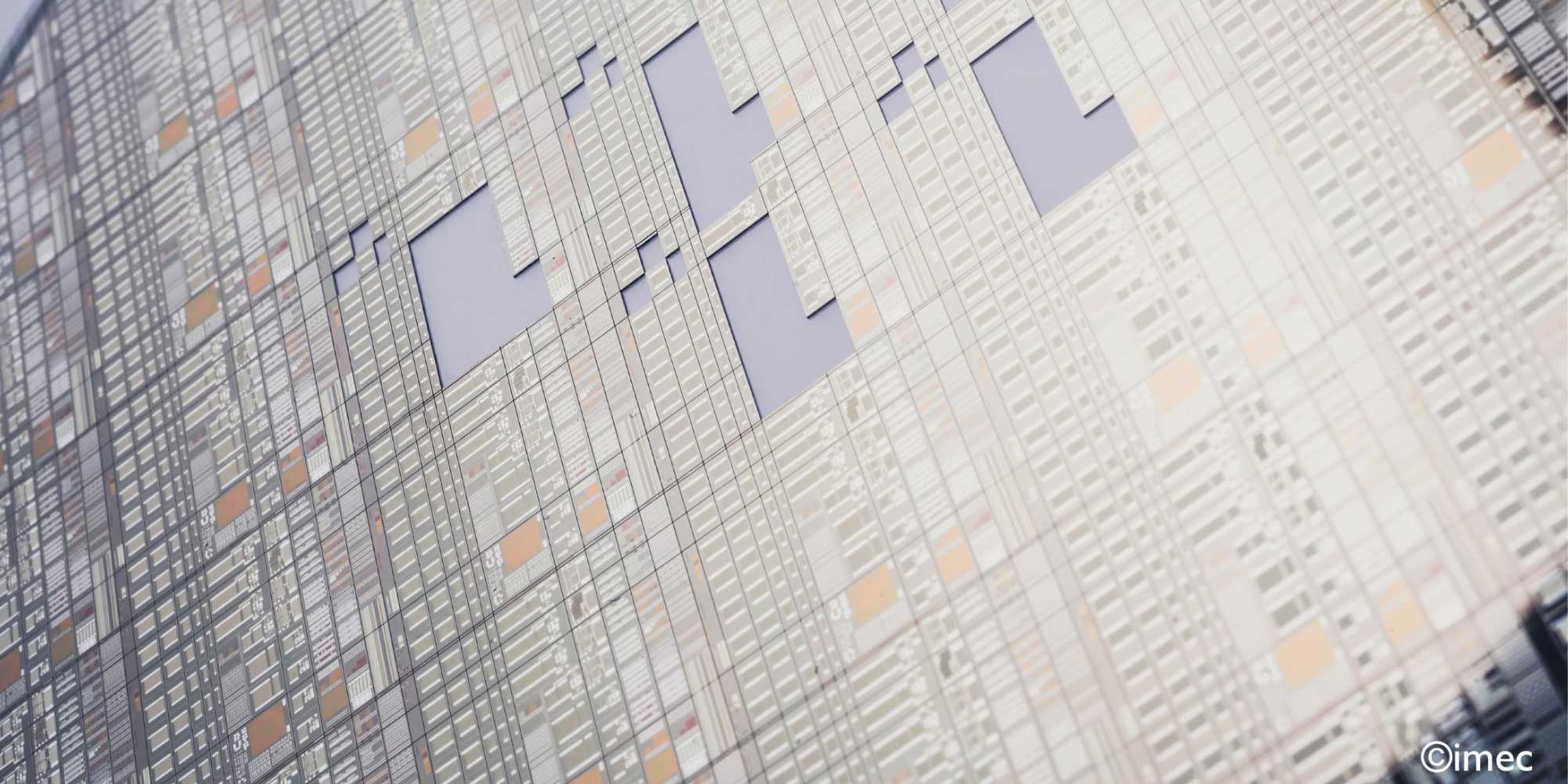

Imec researchers have worked out a better way: grow GaN on SOI wafers and use trench isolation. This technique has been extensively tested, with excellent results.

In 2022, d-mode HEMTs and Schottky barrier diodes were also added to imec's GaN IC portfolio. Check out the research update

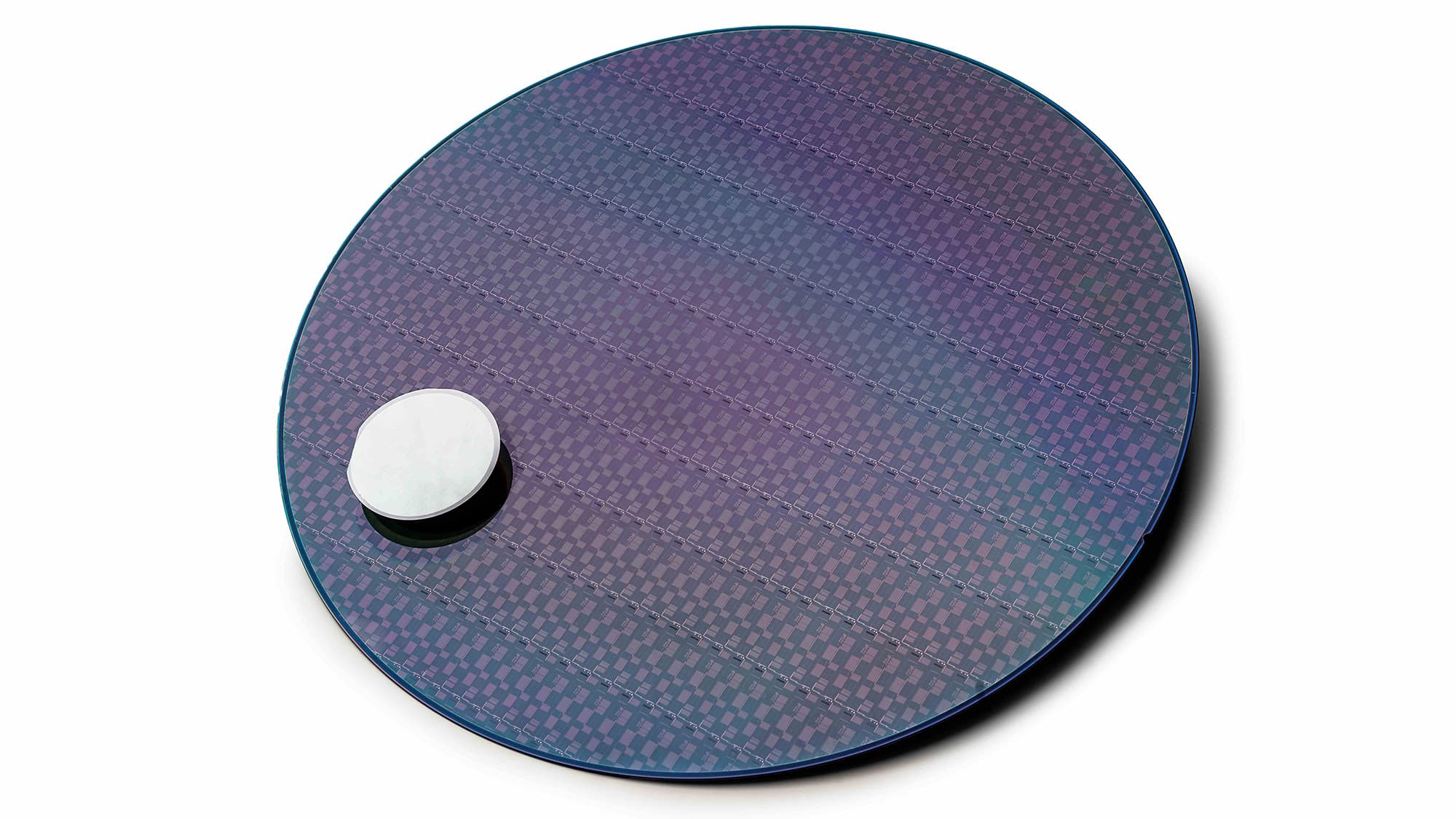

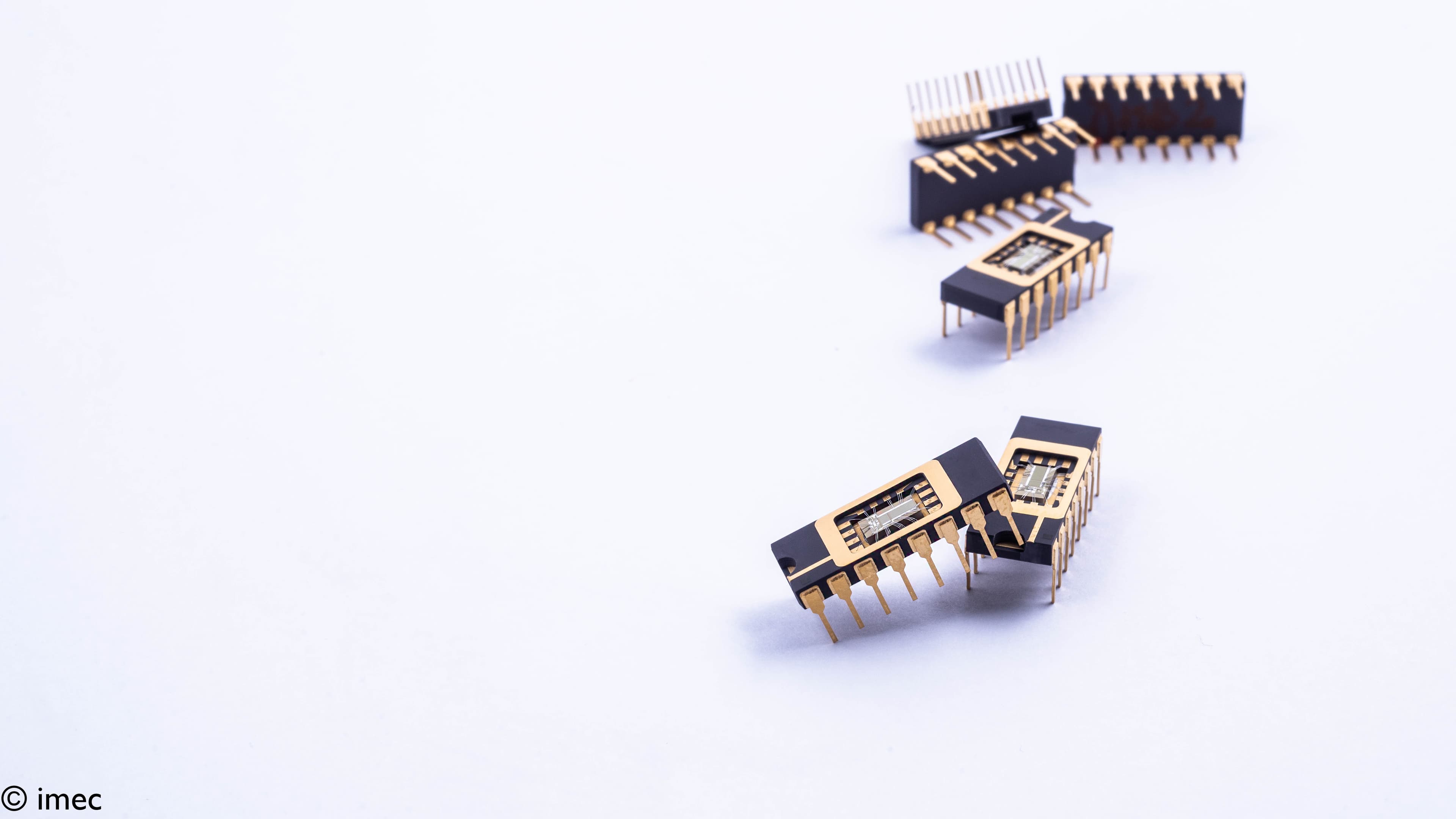

MPW makes GaN-IC’s affordable

Are you looking to produce Gan-IC’s in small quantities or prototypes? You have easy and affordable access to imec’s expertise and its state-of-the-art facilities. Take advantage of our Multi-Project Wafer service (MPW) in order to share mask, processing and engineering costs with multiple partners. And design your own GaN-IC’s using our Process Design Kit (PDK).

If you’re ready to produce medium to high volumes of GaN-IC’s, feel free to contact us for dedicated mask runs.

Visit this page for more info on the technology, run schedules and prices.